A low-speed wind tunnel model powered flight test power system

A power system and flight experiment technology, applied in aerodynamic tests, measuring devices, instruments, etc., can solve the problems of aircraft model design difficulties, low engine power density, and inability to install aircraft models, etc., and achieve good engineering application prospects, Low frictional resistance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

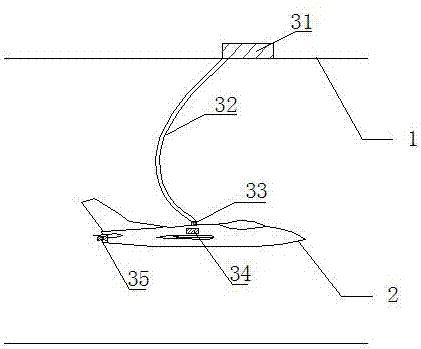

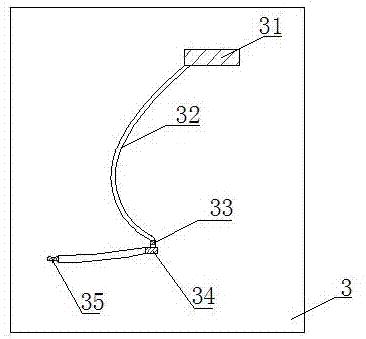

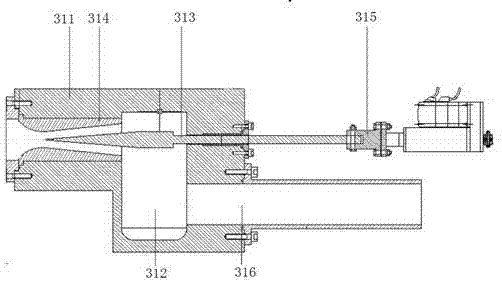

[0029] In Example 1, see figure 1 and figure 2 As shown, the present invention proposes a low-speed wind tunnel model driving force flight test power system, including a wind tunnel test section 1, an aircraft model 2 and a power system 3, and the power system 3 includes a needle valve 31, a high-pressure hose 32, Swivel joint 33, resident chamber 34 and nozzle pipe 35; the needle valve 31 is arranged outside the wind tunnel test section 1, one end of the high-pressure hose 32 is connected to the needle valve 31 and the other end of the high-pressure hose 32 is connected to the rotary The rotating end of joint 33, the fixed end of described rotary joint 33 is fixed on the top of aircraft model 2, and described resident chamber 34 places the inside of aircraft model 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com