Sub-critical miniature reactor driven by neutron tubes

A neutron tube and reactor technology, which is applied in the field of subcritical micro-reactors, can solve the problems of small geometric size, high mobility, uneven spatial distribution of neutron flux density, etc., and achieves small geometric size and neutron output. The effect of stabilizing and simplifying the core design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

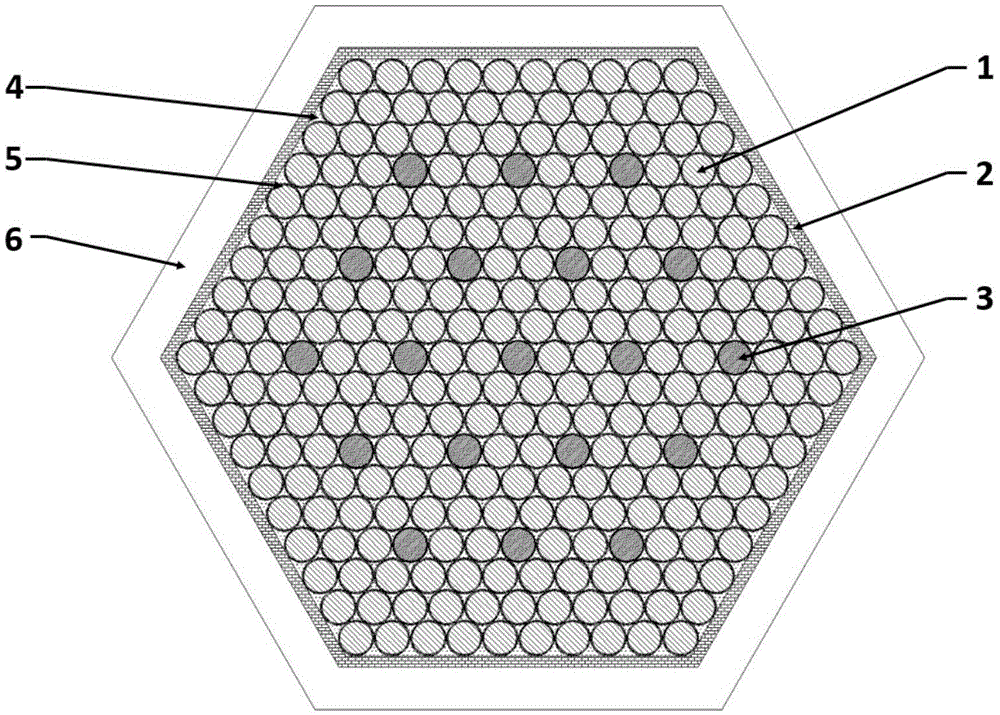

[0017] Such as figure 1 As shown, the present invention includes: cylindrical fuel rod 1, hexagonal reflector 2 at the core boundary, cylindrical neutron tube neutron source 3, liquid coolant 4, cylindrical rod cladding tube 5, outside the core area Hexagonal shield 6. Cylindrical neutron tube neutron sources are arranged in a uniform and dispersed manner, and the specific number of cylindrical neutron tube neutron sources and the specific location of cylindrical neutron tube neutron sources are not limited.

[0018] When the reactor is started, there is no need to add other external sources, all cylindrical neutron tube neutron sources are started at the same time, and the neutron flux density configuration required for the normal operation of the reactor can be obtained in a short time, which is different from the start-up of a conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com