Rechargeable battery and its electrolyte formulation

A technology for rechargeable batteries and non-aqueous electrolytes, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, lithium batteries, etc., can solve the problems of increasing volume, weight complexity and cost, damaging battery performance and life, and limiting battery applications, etc. Achieve the effect of improving battery charge-discharge cycle efficiency, improving power, and reducing gassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0095] Example 1: Electrolyte Formulation

[0096] Example electrolyte formulations according to the present disclosure include: LiPF 6 , 1.0M; LiTFSI, 0.15M; EC, 40vol.%; EMC, 45vol.%; DEC, 10vol.%; PC, 5vol.%; ES, 1.5wt.%; VC, 1wt.%; wt.%.

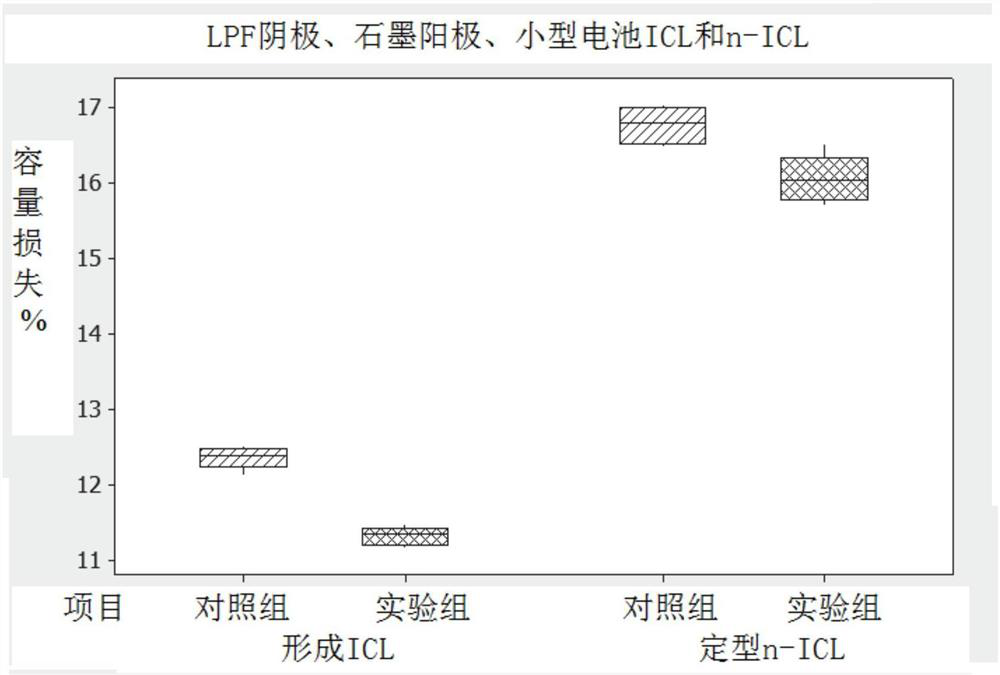

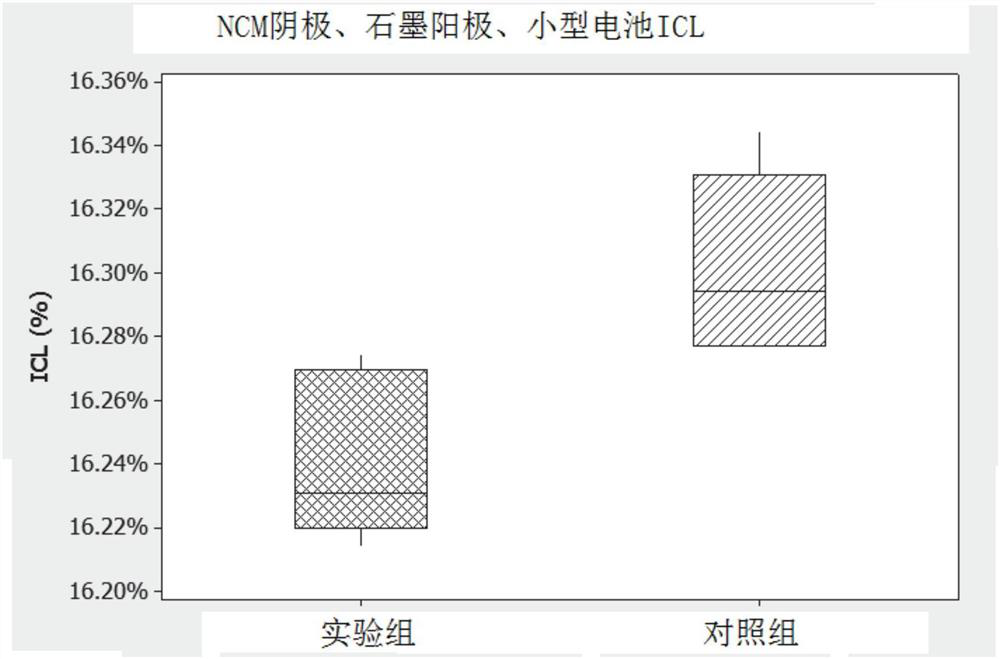

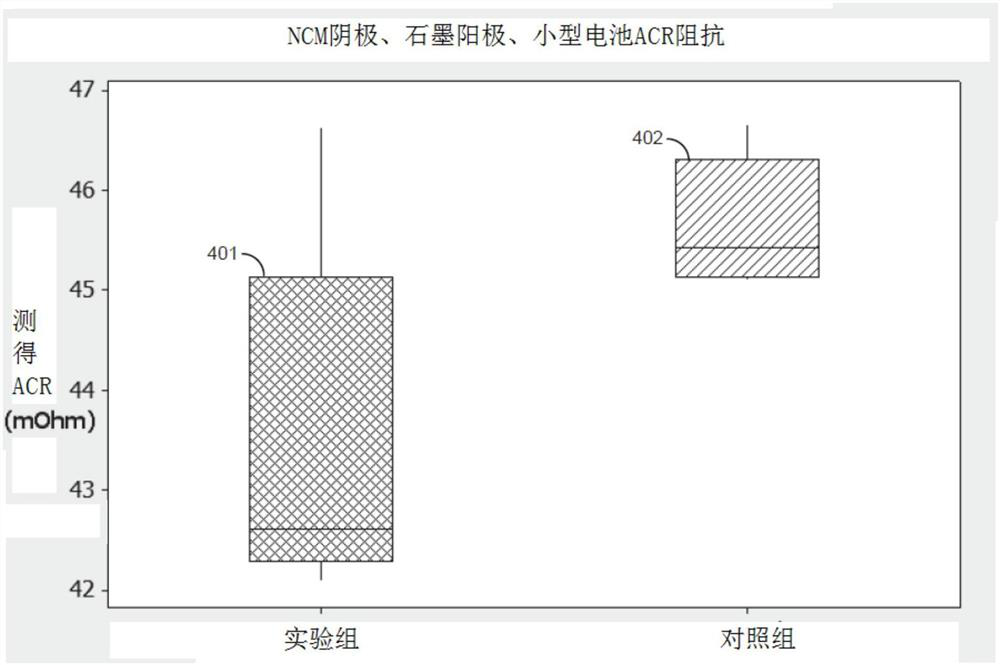

[0097] The electrolyte formulations were compared with the control electrolyte formulations, as follows and with reference to Figure 1 to Figure 10 discussed. The electrolyte formulation exhibits improved performance in low and high temperature tests relative to a control electrolyte formulation.

[0098] The first control electrolyte formulation contains: LiPF 6 EC, 30 vol.%; EMC, 55 vol.%; DEC, 10 vol.%; PC, 5 vol.%; ES, 1 wt.%; and VC, 2 wt.%. The first control electrolyte formulation contained the sulfonyl-containing first additive ES, but did not provide the salt solution and anti-gassing additives of the present application.

[0099] The second control electrolyte formulation contains: LiPF 6 , 1.15M; EC, 35vol.%; EMC, 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com