a mos 2 /c/livpo 4 f Composite cathode material and preparation method thereof

A composite positive electrode material and composite material technology, which is applied in the field of lithium ion battery materials, can solve the problems of poor high-temperature cycle stability of lithium vanadium phosphate positive electrode materials, and achieve the effect of improving electronic conductivity, good electronic conductivity, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

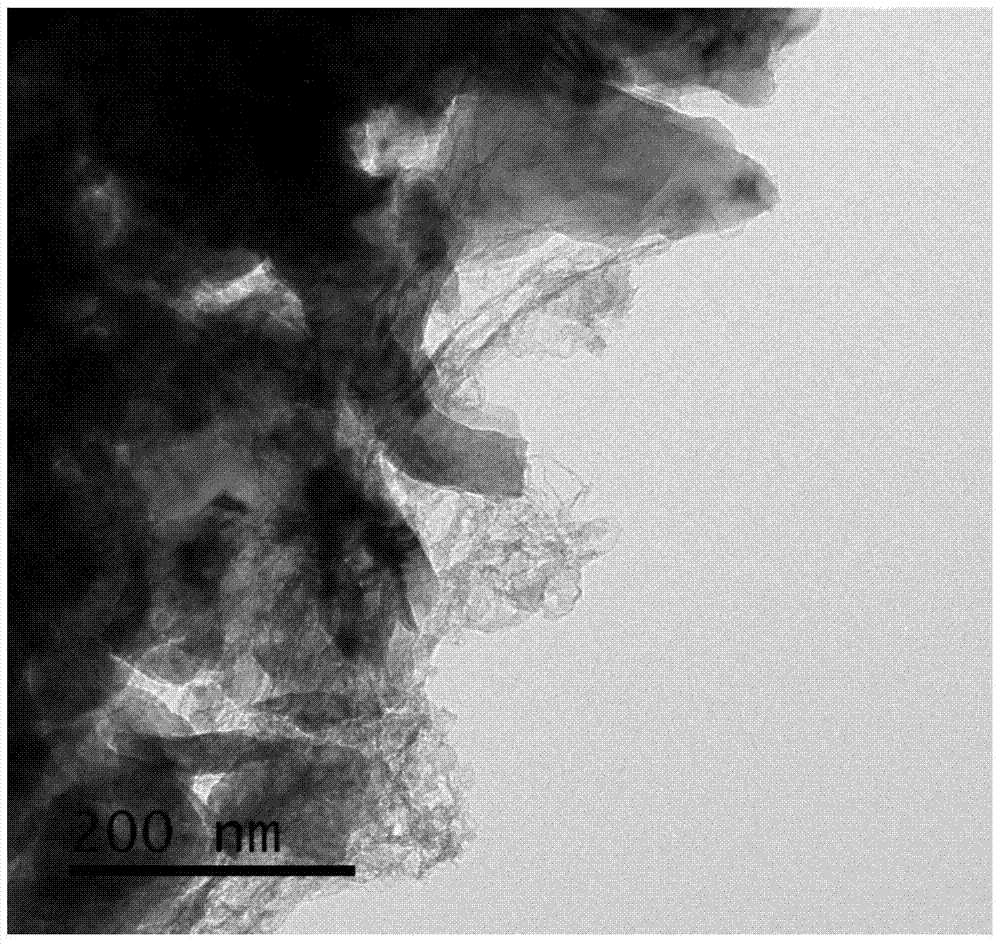

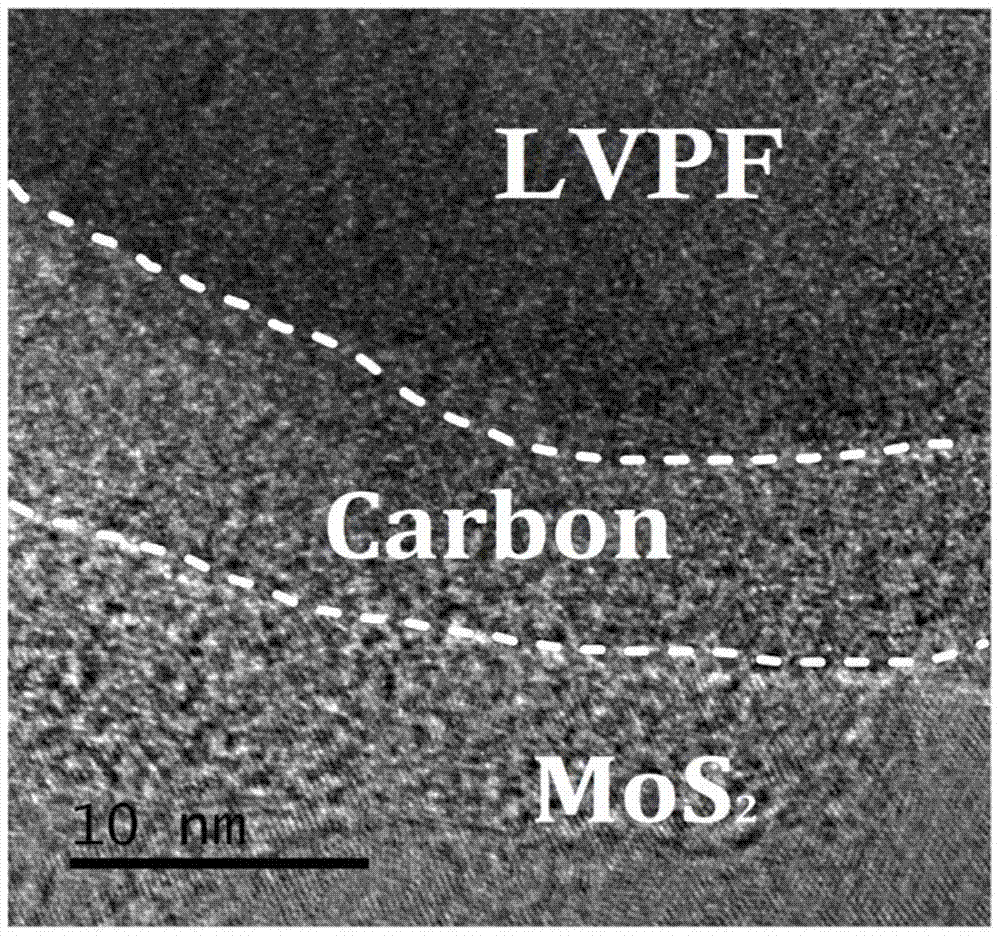

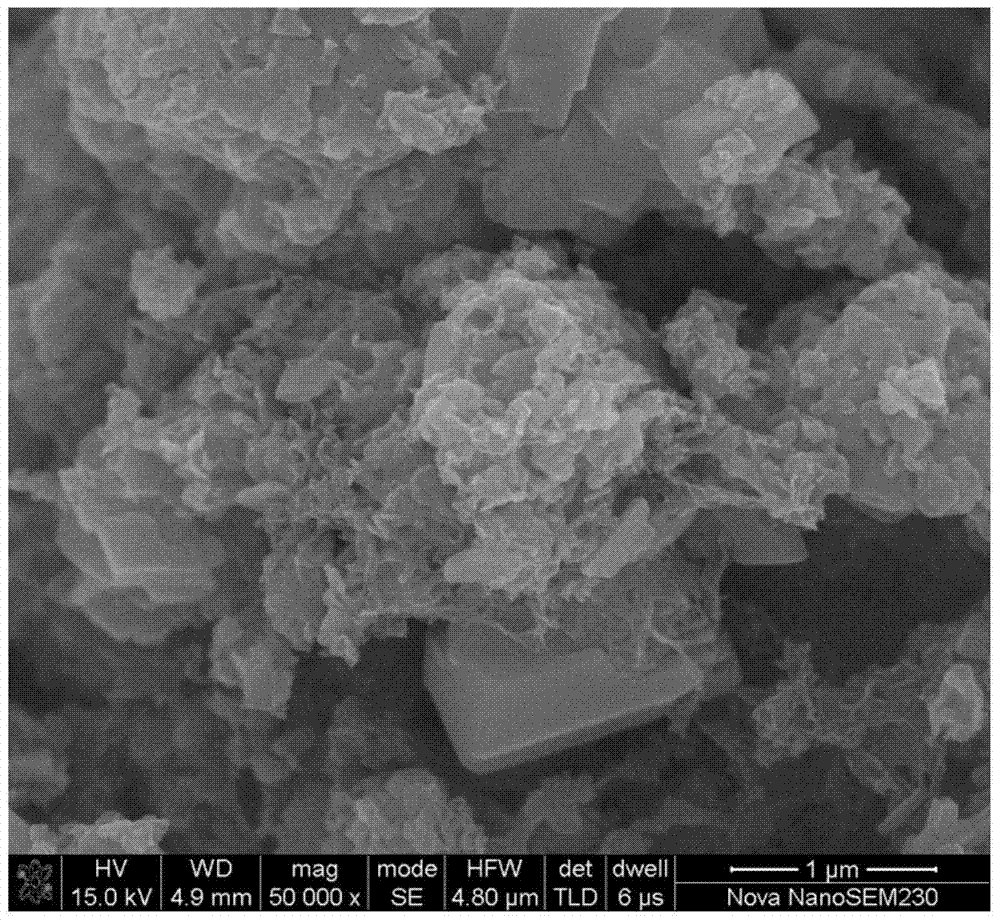

[0042] A kind of MoS of the present invention 2 / C / LiVPO 4 F composite cathode material, multilayer core-shell structure, with LiVPO 4 F is the inner core, the middle layer is amorphous carbon, and the outermost layer is MoS 2 ;MoS 2 The mass accounted for LiVPO 4 2 wt% of the mass of F; the mass of amorphous carbon accounts for LiVPO 4 1.56 wt% of F mass.

[0043] MoS of this example 2 / C / LiVPO 4 The preparation method of F composite cathode material, comprises the following steps:

[0044] (1) Preparation of C / LiVPO coated with amorphous carbon by mechanical activation 4 F composite material; the mass of C in the synthesized composite cathode material accounted for LiVPO 4 1.56 wt% of F mass.

[0045] (2) Dissolve ammonium molybdate and thiourea in distilled water to prepare a solution, and react in a reactor at 180 °C for 20 h to synthesize layered MoS 2 .

[0046] (3) The layered MoS prepared in step (2) 2 , slowly added to the alcohol, accompanied by continuo...

Embodiment 2

[0054] A kind of MoS of the present invention 2 / C / LiVPO 4 F composite cathode material, multilayer core-shell structure, with LiVPO 4 F is the inner core, the middle layer is amorphous carbon, and the outermost layer is MoS 2 .

[0055] MoS of this example 2 / C / LiVPO 4 The preparation method of F composite cathode material, comprises the following steps:

[0056] (1) Preparation of C / LiVPO coated with amorphous carbon by mechanical activation 4 F composite material; the mass of C in the synthesized composite cathode material accounted for LiVPO 4 1.3 wt% of F mass.

[0057] (2) Dissolve ammonium molybdate and thiourea in distilled water to prepare a solution, and react in a reactor at 180°C for 16 hours to synthesize layered MoS 2 .

[0058] (3) The layered MoS prepared in step (2) 2 , slowly added to the alcohol, accompanied by continuous stirring and ultrasonic assistance during the addition process, continued ultrasonic assisted oscillation for 1 hour after the a...

Embodiment 3

[0067] A kind of MoS of the present invention 2 / C / LiVPO 4 F composite material, a multilayer core-shell structure, with LiVPO 4 F is the inner core, the middle layer is amorphous carbon, and the outermost layer is MoS 2 ;MoS 2 The mass accounted for LiVPO 4 2 wt% of the mass of F; the mass of amorphous carbon accounts for LiVPO 4 2.0 wt% of F mass.

[0068] MoS of this example 2 / C / LiVPO 4 The preparation method of F composite material, comprises the following steps:

[0069] (1) Preparation of C / LiVPO coated with amorphous carbon by mechanical activation 4 F composite material; the mass of C in the synthesized composite cathode material accounted for LiVPO 4 2.0 wt% of F mass.

[0070] (2) Dissolve ammonium molybdate and thiourea in distilled water to prepare a solution, and react in a reactor at 220°C for 14 hours to synthesize layered MoS 2 .

[0071] (3) The layered MoS prepared in step (2) 2 , slowly added to the alcohol, accompanied by continuous stirring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com