Modular nozzle having wear-resistant housing part

A component and nozzle technology, applied in the field of modular nozzles with wear-resistant shell components, can solve the problems of large expenditure, high manufacturing cost, and insufficient economy, and achieve the effects of rapid manufacturing, reduced manufacturing cost, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

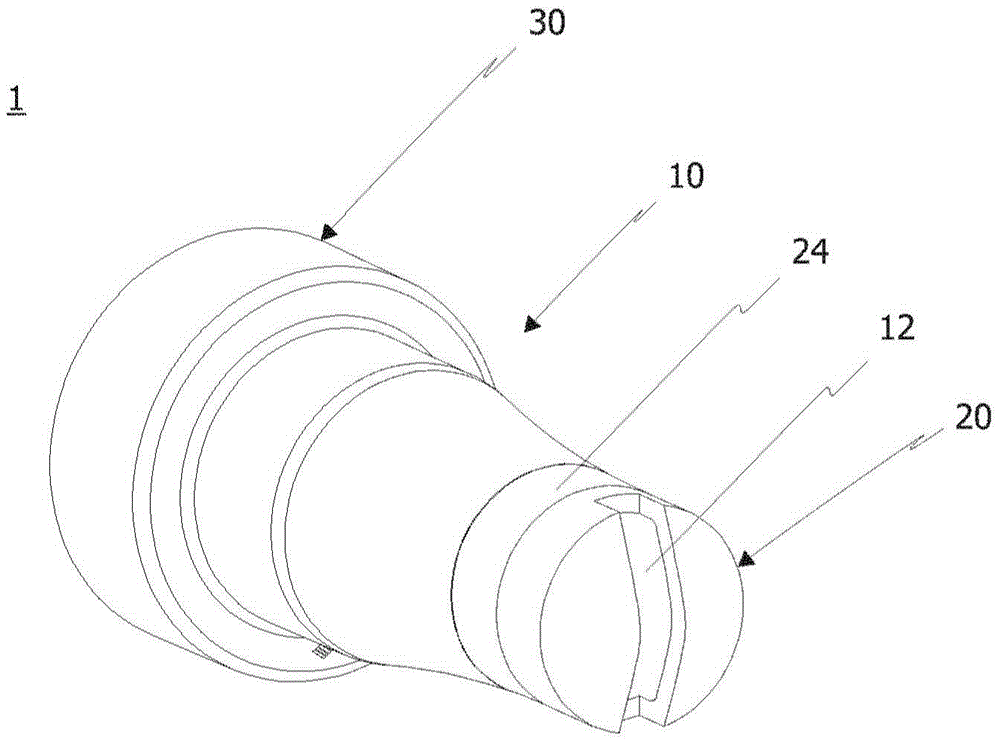

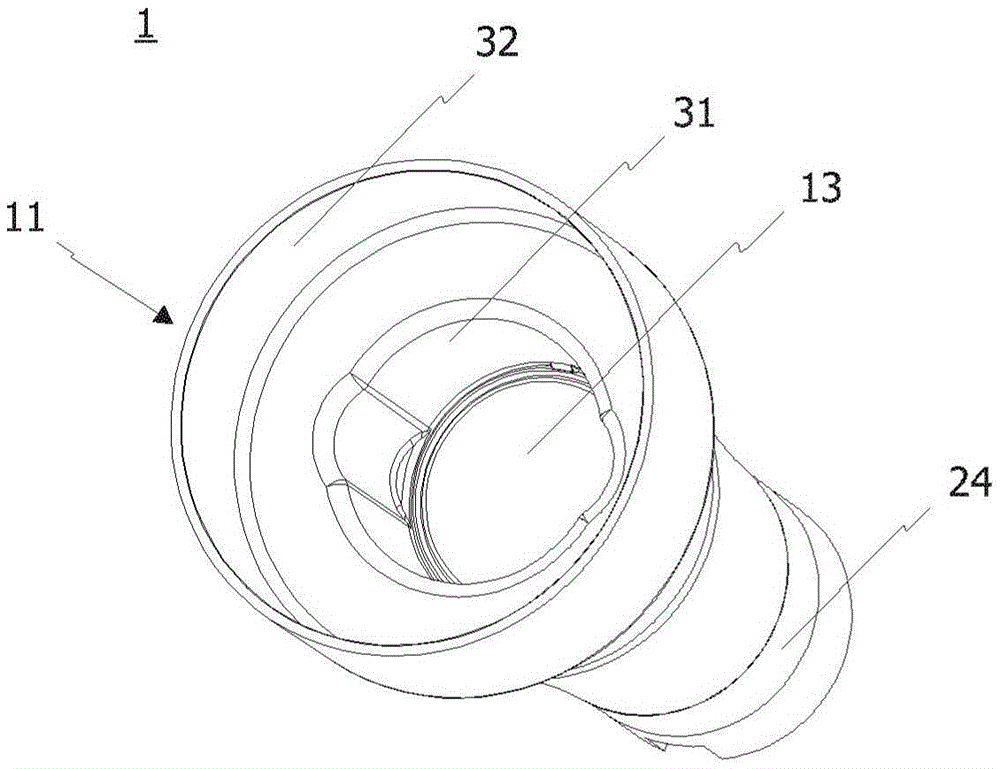

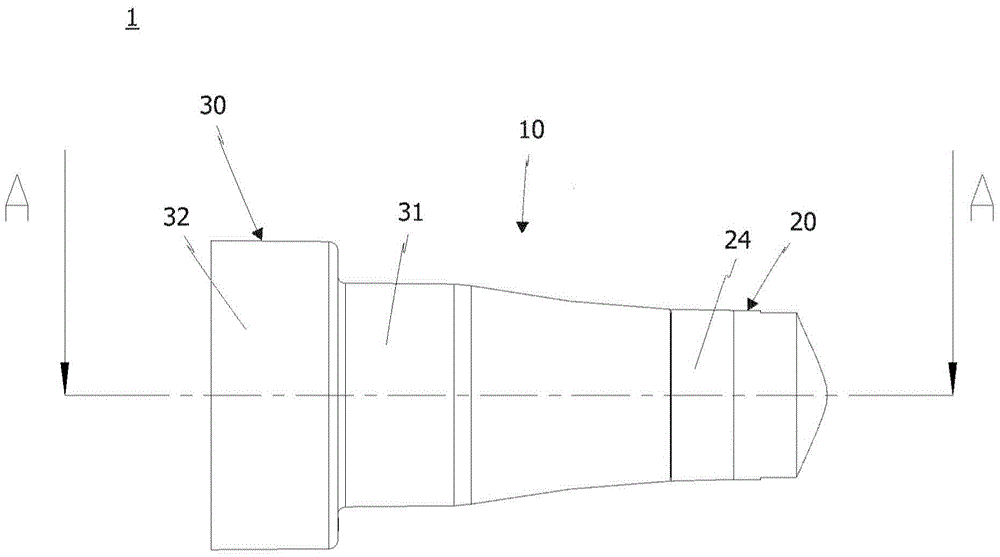

[0028] Figure 1a with Figure 1b A perspective view of a first embodiment of a nozzle 1 according to the invention for spraying a coating material is shown. The nozzle 1 for spraying coating material, in particular coating powder, has a housing with a first opening 11 on the input side and a second opening 12 on the output side. In this case, the two openings 11 and 12 are at least partially connected to one another by means of a through-channel 13 , which in the embodiment shown is in particular cylindrically designed. The through-channel 13 serves to enable coating material, eg coating powder, to flow through the nozzle 1 . For this purpose, the nozzle 1 is detachably connected to a spraying device (not shown) in such a way that the through-channel 13 is aligned with the powder discharge channel of the spraying device.

[0029] about Figure 3a , Figure 3b as well as Figure 4a with Figure 4b It will also be described that the housing has an inner housing part 20 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com