Atomized electronic cigarette based on electromagnetic induction heating

An electromagnetic induction heating and electromagnetic induction coil technology, which is applied in the field of electronic cigarettes, can solve the problems of dry burning of oil-absorbing cotton, difficult heat diffusion, and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

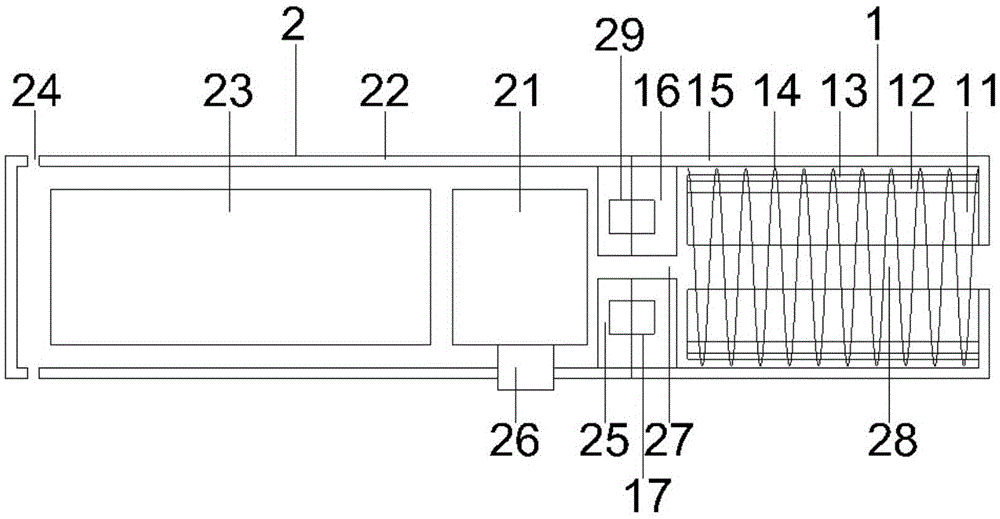

[0022] Such as figure 1 As shown, an atomized electronic cigarette based on electromagnetic induction heating includes an atomizer module 1. The atomizer module 1 includes a right housing 15, and an e-liquid storage part 11 is arranged inside the right housing 15. The e-liquid storage part 11 The metal heating tube 12 is set on the outside, and the metal heating tube 12 is wrapped with a heat insulating layer 13, and the heat insulating layer 13 is wrapped with an electromagnetic induction coil 14;

[0023] The atomizer module 1 is connected with a power module 2, the power module 2 includes a left casing 22, and a power supply 23 is arranged inside the left casing 22, and the power supply 23 is connected with a PCB control circuit board 21, and the PCB control circuit board 21 is provided with a Switch 26 external to housing 22 .

[0024] Right housing 15 is provided with right connector 16, and right connector 16 is provided with right electrode column 17, and right electro...

Embodiment 2

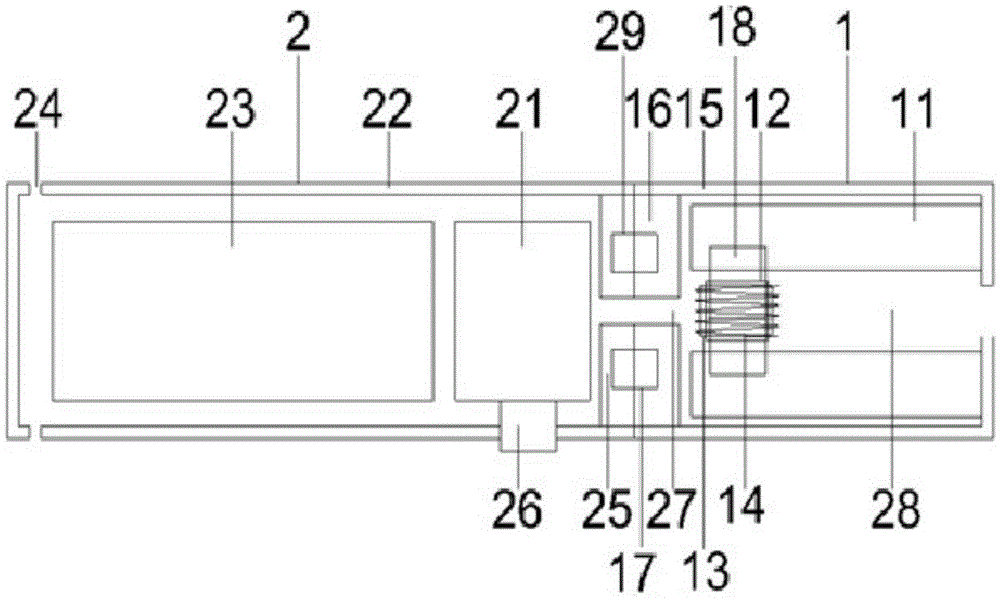

[0027] Such as figure 2 As shown, an atomized electronic cigarette based on electromagnetic induction heating includes an atomizer module 1 and a power supply module 2. The atomizer module 1 includes a right housing 15, and the right housing 15 is equipped with an e-liquid storage component 11. There is a channel 28 in the center of the oil storage part 11, and an oil guide part 18 is connected to the channel 28 of the smoke oil storage part 11, and the oil guide part 18 is used to conduct smoke oil or other liquids from the smoke oil storage part 11; the oil guide part 18 is covered with a metal heating tube 12, the metal heating tube 12 is covered with a heat insulation layer 13, and the metal heating tube 12 is wrapped with an electromagnetic induction coil 14;

[0028] The power supply module 2 and the connection method between the power supply module 2 and the atomizer module 1 are the same as in the first embodiment.

[0029] combine figure 2 As shown in the schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com