Double-station seamless underwear hot press

A technology of seamless underwear and hot press, which is applied in the direction of sewing tools and other directions, can solve the problems of many product wrinkles, slow processing, low degree of automation, etc., and achieve the effect of improving automation performance, smooth surface and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical scheme in the embodiment of the present invention is described below in conjunction with accompanying drawing:

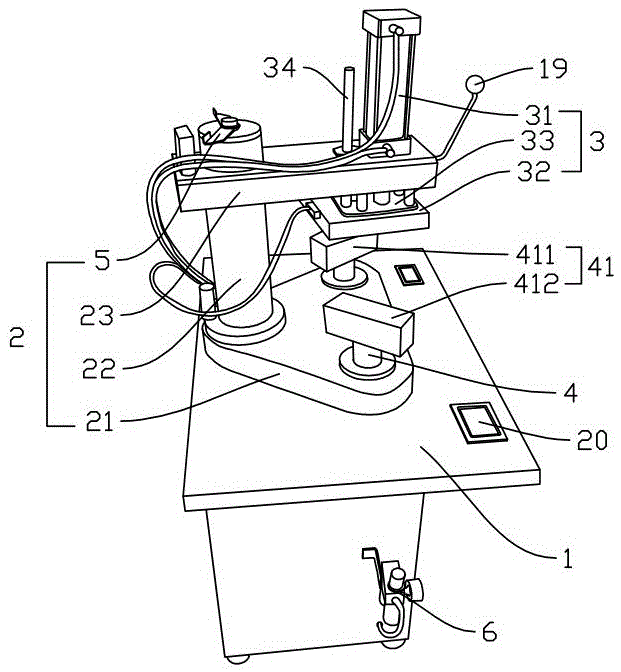

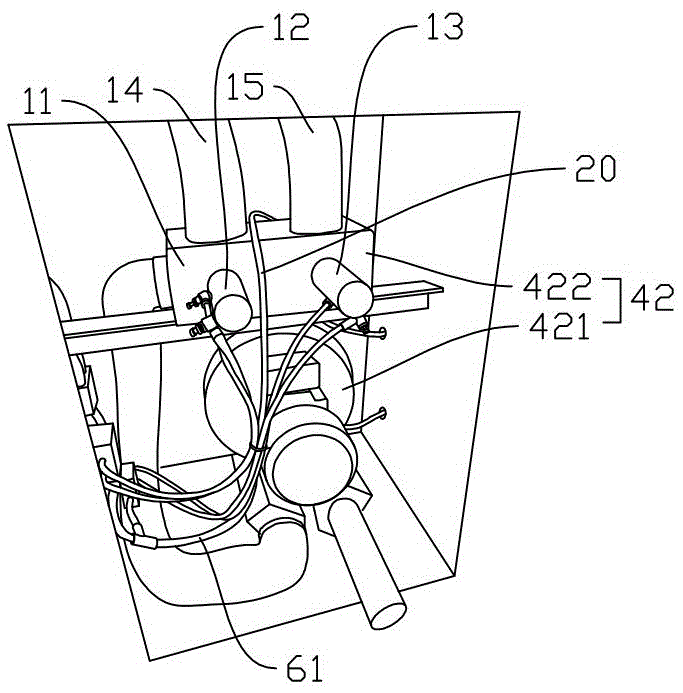

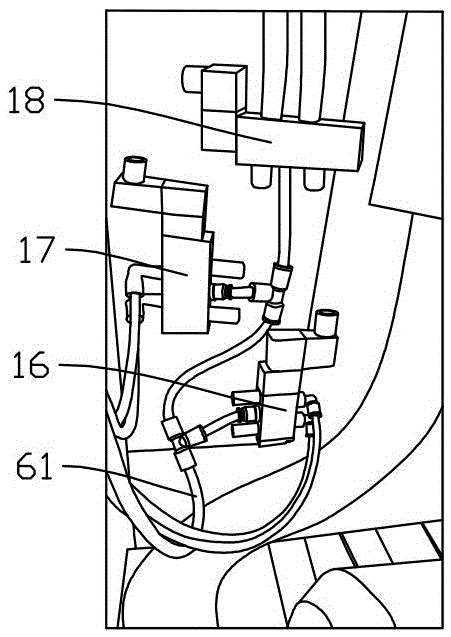

[0030] figure 1 It is an overall schematic diagram showing a double-station seamless underwear heat press, including a workbench 1, a head swing device 2, a heat press device 3 and a pressure device 4, and the heat press device 3 and the pressure device 4 are both arranged on the swing On the head device 2, the head swing device 2 is arranged on the workbench 1.

[0031] The swing head device 2 includes a base 21, a rotating shaft 22, a support member 23 and a limiter 5, the base 21 is arranged on the table top of the workbench 1, the rotating shaft 22 is vertically arranged on the base 1, and the supporting member 23 is vertically arranged on the rotating shaft 22, The limit device 5 includes a limit switch 51 and a limit member 52, the limit switch 52 is arranged on the top of the rotating shaft 22, the limit switch 51 is arranged at the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com