An automatic batching and mixing granulation system

An automatic batching and mixing technology, which is applied in the direction of granulation in static tanks/troughs, etc., can solve problems such as the impact of feeding accuracy, long feeding time, and low work efficiency, so as to avoid dust leakage, facilitate inspection, and improve efficiency. and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

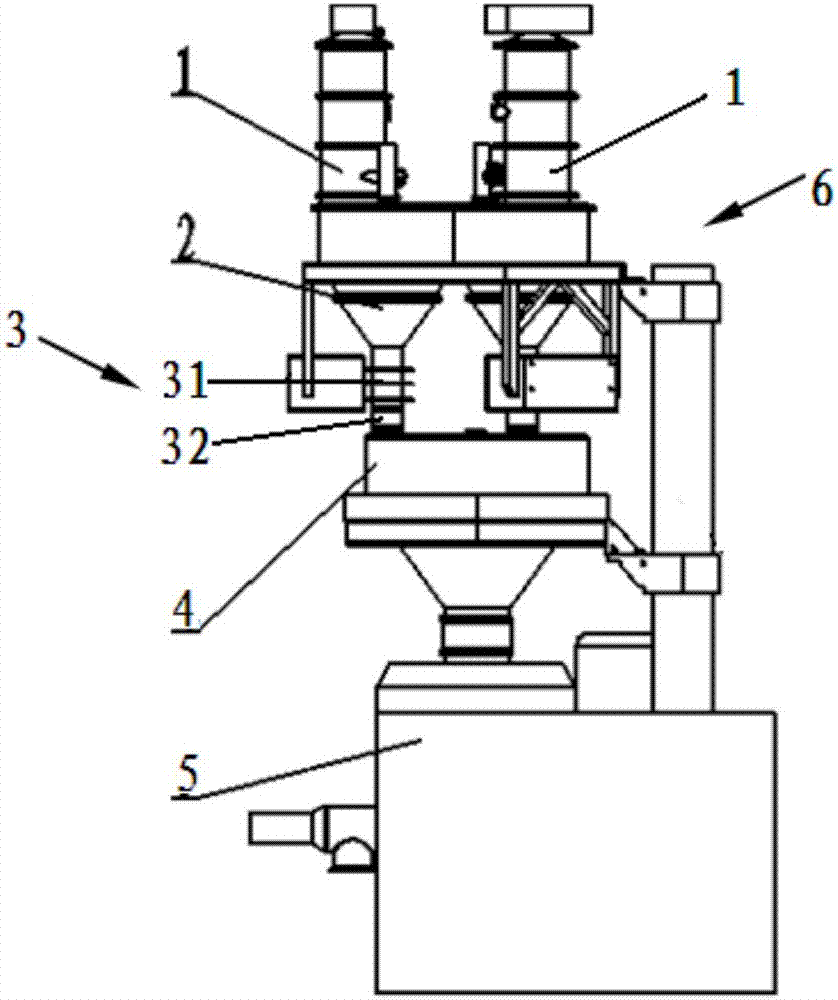

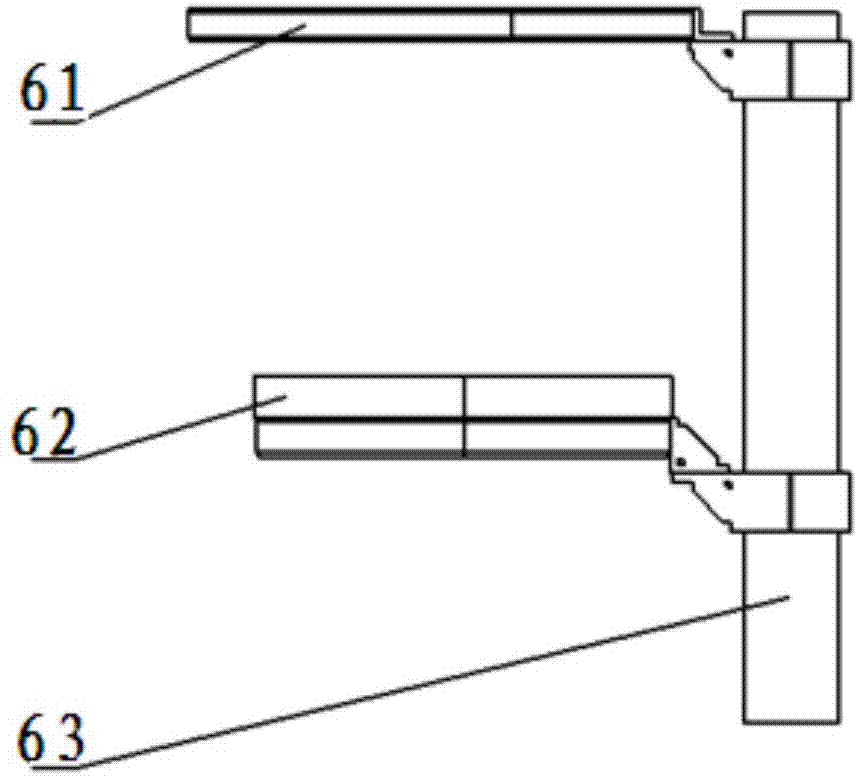

[0027] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0028] In the prior art, dust is easily generated during wet mixing granulation, which affects the health of operators and production safety, and also causes deviations in the weight of materials used for granulation, which affects the quality of granulated products. In addition, in the prior art, it is impossible to accurately measure the materials during the granulation process, which seriously affects the production efficiency. The invention avoids dust leakage by designing the automatic batching, mixing and granulating system into a closed structure; realizes automatic feeding through negative pressure and gravity; and automatically completes the metering of materials through a metering unit....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com