Electrostatic adsorption disc for preventing circulating liquid from leaking

An electrostatic adsorption and circulating liquid technology, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of increasing the concentration of total volatile organic compounds, falling out of internal circulation droplets, and increasing metal loss defects. The effect of reducing deployment and replacement costs, ensuring high yields, and preventing metal loss defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

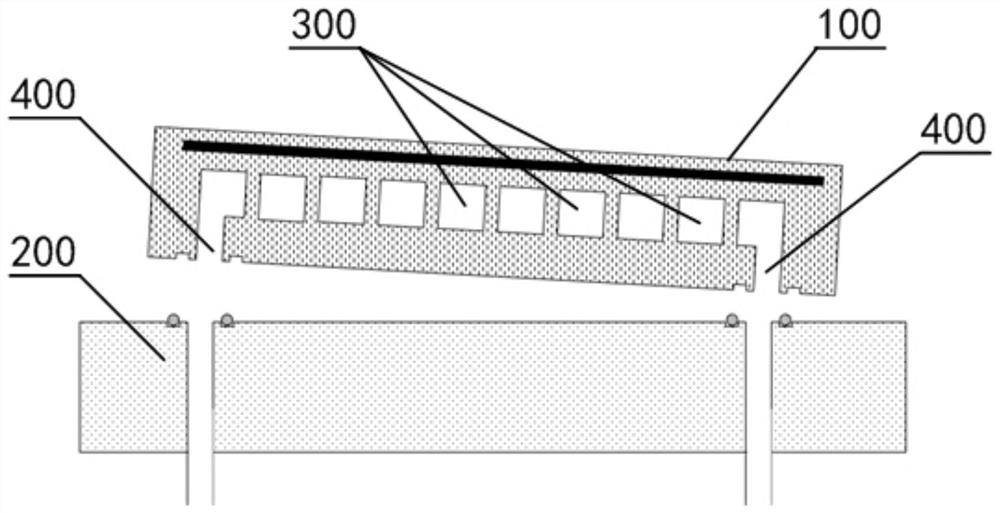

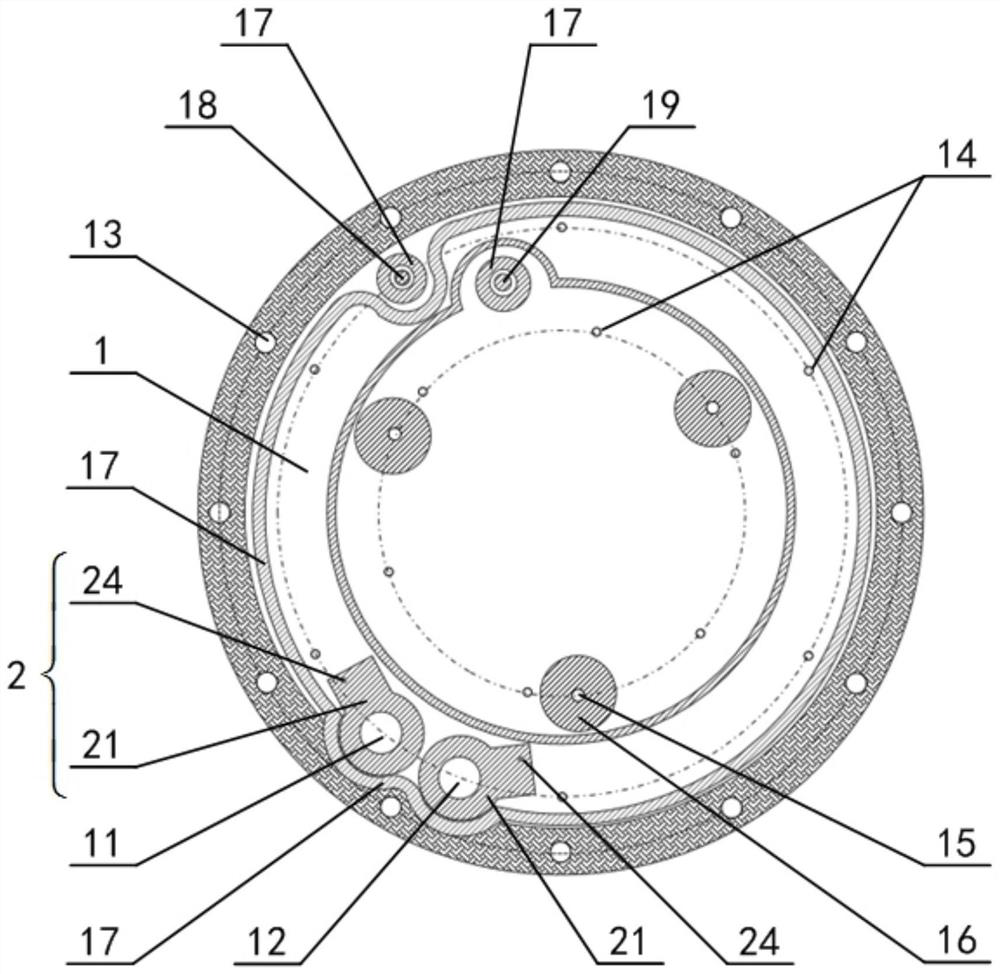

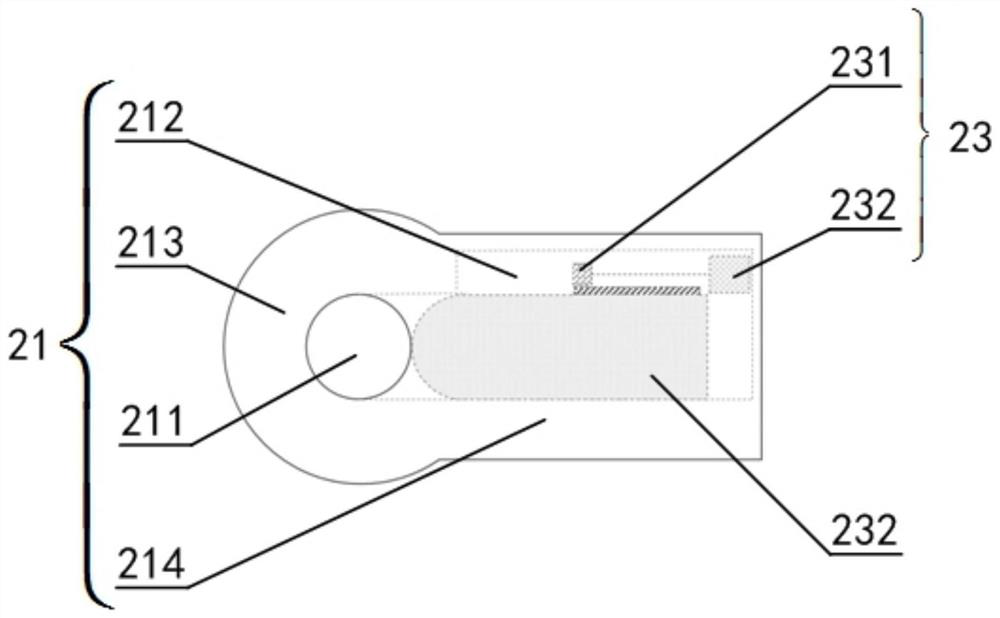

[0039] Such as Figure 2-6 As shown, the electrostatic adsorption disc for preventing circulating fluid leakage provided in this embodiment includes a adsorption disc body 1, and a valve assembly 2 is embedded on the bottom surface of the adsorption disc body 1 at the circulating fluid port, Wherein, the circulating fluid port includes a circulating fluid inlet 11 and a circulating fluid outlet 12; the valve assembly 2 includes an embedded plate-shaped valve body 21, a valve plate 22 and a valve plate propulsion controller 23, wherein, in the The bottom surface of the embedded plate valve body 21 is provided with a circulating fluid through hole 211 for aligning with the circulating fluid port and having the same diameter as the circulating fluid port. There is a transverse cavity 212 communicated with the circulating fluid through hole 211 inside, the valve plate 22 and the valve plate advance controller 23 are respectively located in the transverse cavity 212, and the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com