Method for removing rust on outer wall of petroleum drill rod

A technology for oil drill pipes and drill pipes, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as low efficiency and inconvenient operation, and achieve simple and convenient operation, convenient operation, and adjustment The effect of the height of the guide rail is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

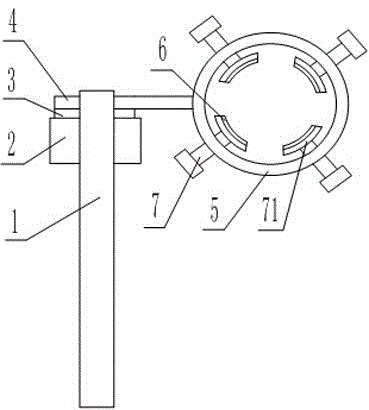

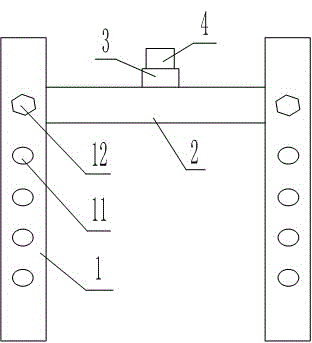

[0037] Such as figure 1 , figure 2 , image 3 Shown, a kind of oil drill pipe outer wall derusting method comprises the following steps:

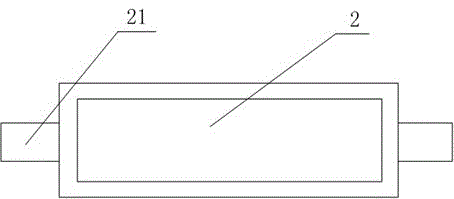

[0038] 1) Use a cleaning device to scrape off the dirt on the outer wall of the drill pipe. The cleaning device includes two cooperating bases 1, and the opposite sides of the two bases 1 are provided with through grooves in the vertical direction. The two side walls are provided with threaded through holes I11, and the two ends of the guide rail 2 are provided with flanges 21, and the flanges 21 are provided with threaded through holes II matched with the threaded through holes I11, and the guide rail 2 is connected with the threaded through holes I11 through bolts I12. , The threaded through hole II is fixed between the two bases 1, a slider 3 is set in the guide rail 2, the slider 3 is driven by a motor to move in the guide rail 2, one end of the connecting rod 4 is fixedly connected with the slider 3, and the other One end is connec...

Embodiment 2

[0043] Such as figure 1 , figure 2 , image 3 As shown, this embodiment is based on Embodiment 1, the fixed ring 5 is made of hard aluminum alloy; the fixed ring 5 is an arc-shaped structure; Groove, the two ends of cleaning plate 6 are clamped in 2 draw-in grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com