A servo forging system

A forging, servo motor technology, applied in forging presses, forging presses, forging/pressing/hammer devices, etc., can solve the problem that the press is difficult to meet the rhythm of production line work, to ensure quality, meet takt requirements, reduce The effect of process noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

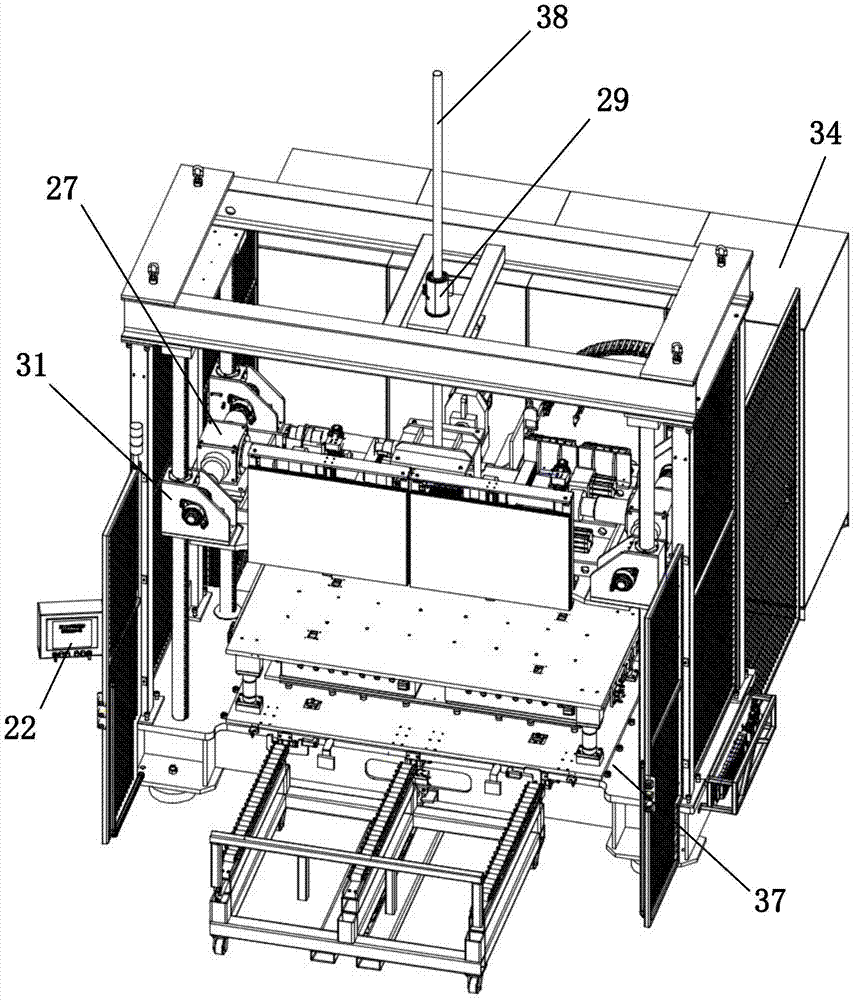

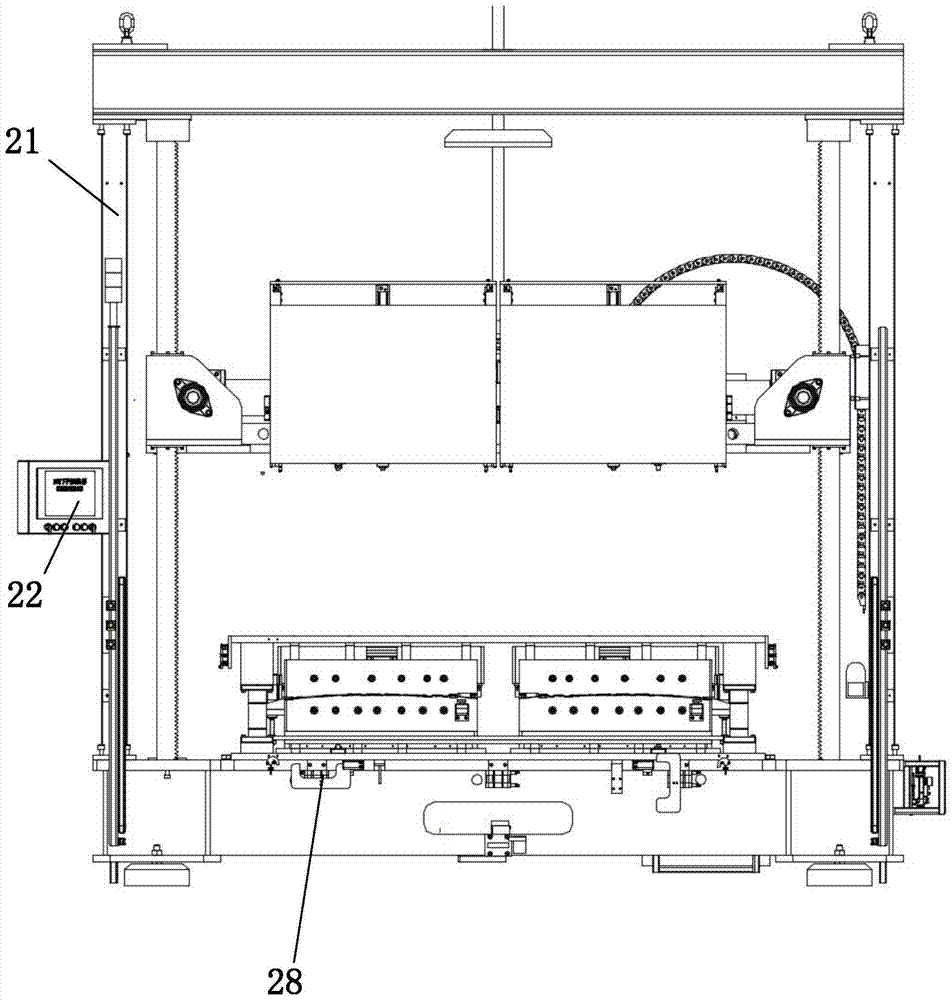

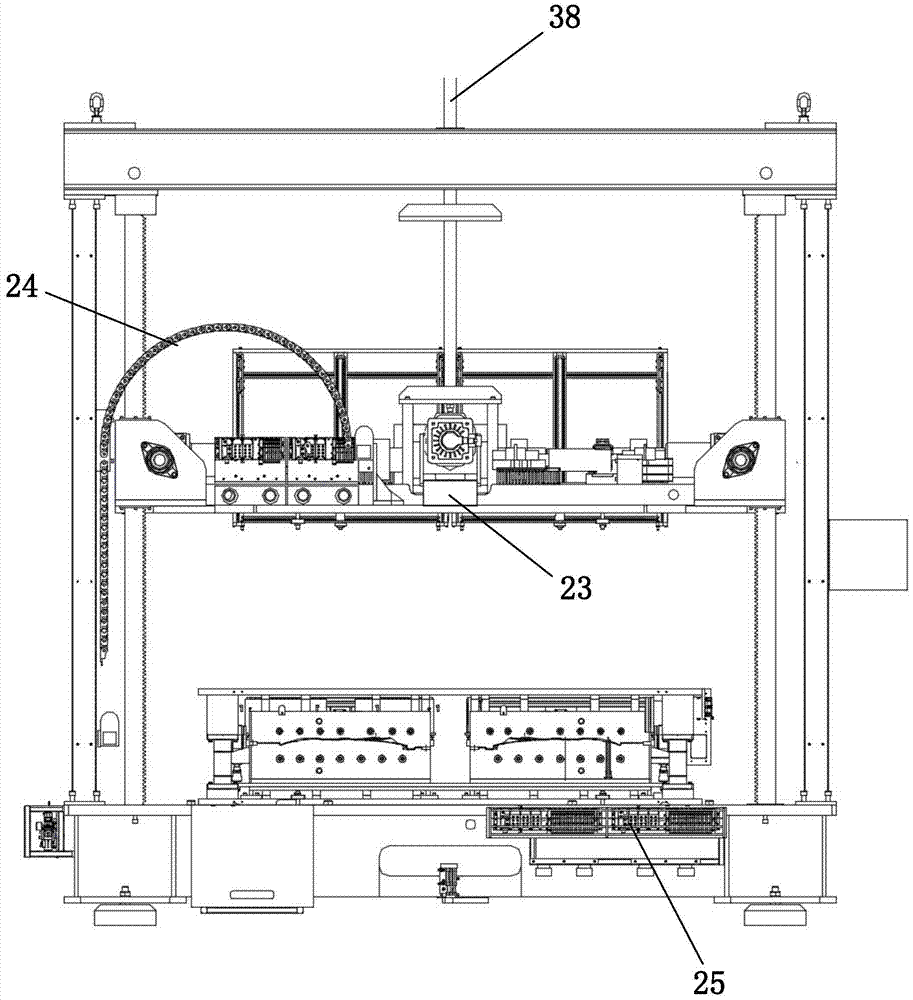

[0032] The present invention will be further described below according to the accompanying drawings.

[0033] like Figure 1 to Figure 13 As shown, connecting plate 35 is provided in the middle of frame 21, and the upper and lower ends of frame 21 are connected by transmission device 31 around connecting plate 35; The front end of the connecting shaft 36 is connected to the connecting shaft 36, and the two ends of the connecting shaft 36 are respectively connected to the gearbox 27 with a synchronous coupling 33; the connecting plate 35 is evenly equipped with four upper mold changing-locking devices 30; located on the frame 21 The lower end of the mold connecting plate 37 is provided with two hot-pressing molds, and the bottom of the mold connecting plate 37 is provided with a lower mold changing-locking device. The structure of the lower mold changing-locking device It is consistent with the structure of the upper mold changing-locking device 30, and the position of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com