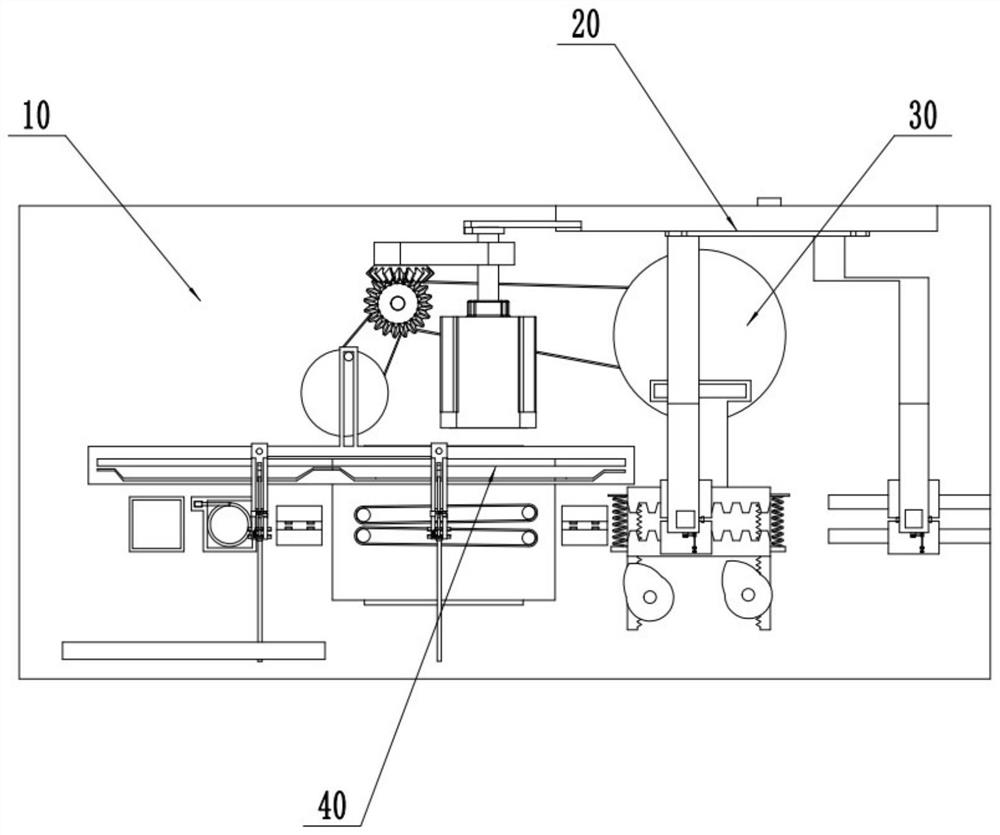

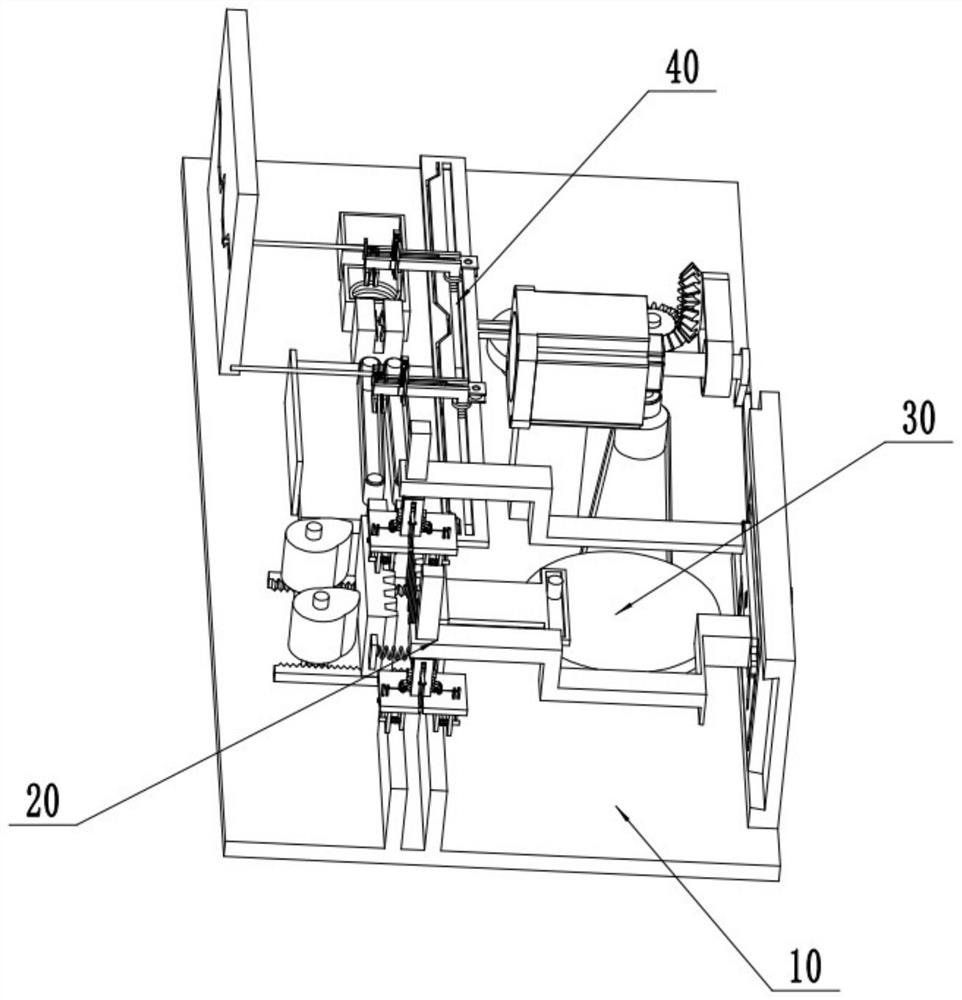

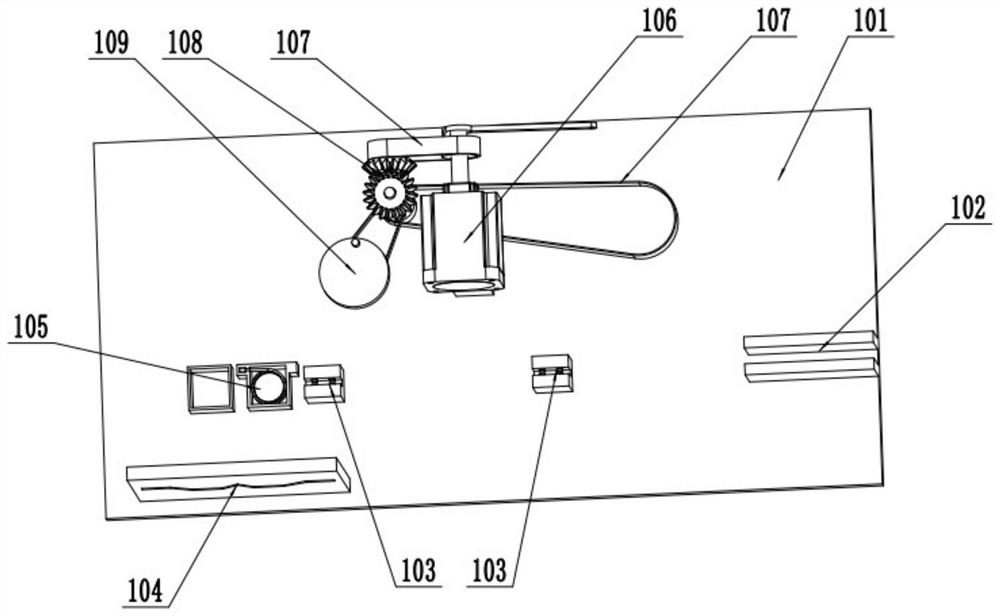

Energy-saving forging cutter machine

A technology of machines and knives, which is applied in the field of energy-saving forging knives machines, can solve the time-consuming problems of forging knives, and achieve the effect of improving work efficiency and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that references in the specification to "one embodiment," "an embodiment," "exemplary embodiment," "some embodiments," etc. mean that the described embodiment may include a particular feature, structure, or characteristic, but not necessarily Each embodiment includes the particular feature, structure or characteristic. Moreover, such phrases are not necessarily referring to the same embodiment. Furthermore, when a particular feature, structure or characteristic is described in conjunction with one embodiment, it is within the knowledge of those skilled in the art to implement such feature, structure or characteristic in conjunction with other embodiments, expressly or not expressly described.

[0025] It should be readily understood that "on", "over" and "on" in this disclosure should be interpreted in the broadest possible manner, such that "on" does not only mean "on" Directly on something" also includes the meaning of "on something" with interveni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com