A robot intelligent free forging and drawing method

A robot intelligence and robot technology, applied in metal processing equipment and other directions, can solve the problems of low production efficiency and poor consistency, and achieve the effect of improving production efficiency and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

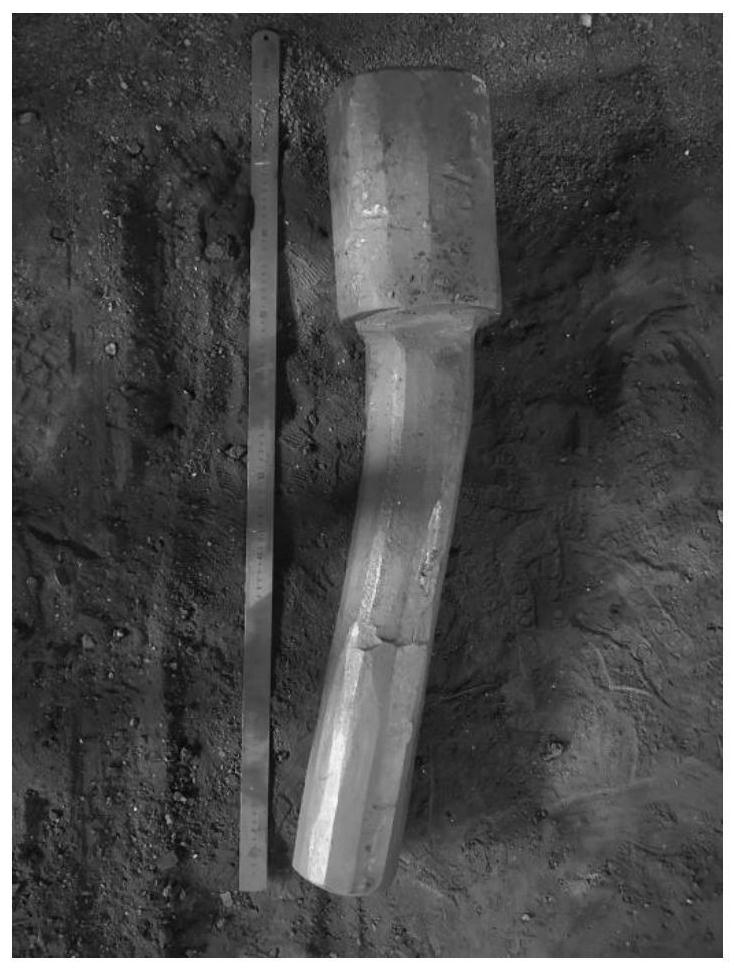

[0028] Such as figure 1 , figure 2 As shown, the traditional manual elongation process relies on the experience of the process planners, and the process parameters are difficult to guarantee. In addition, the process parameters of the traditional manual forging need to be recorded manually, and it is difficult to monitor the temperature and shape of the forging in real time. Defects such as cracks cause problems such as poor product consistency and low pass rate. Such as figure 1 Forgings with axis bending defects shown, figure 2 Forgings with surface crack defects shown.

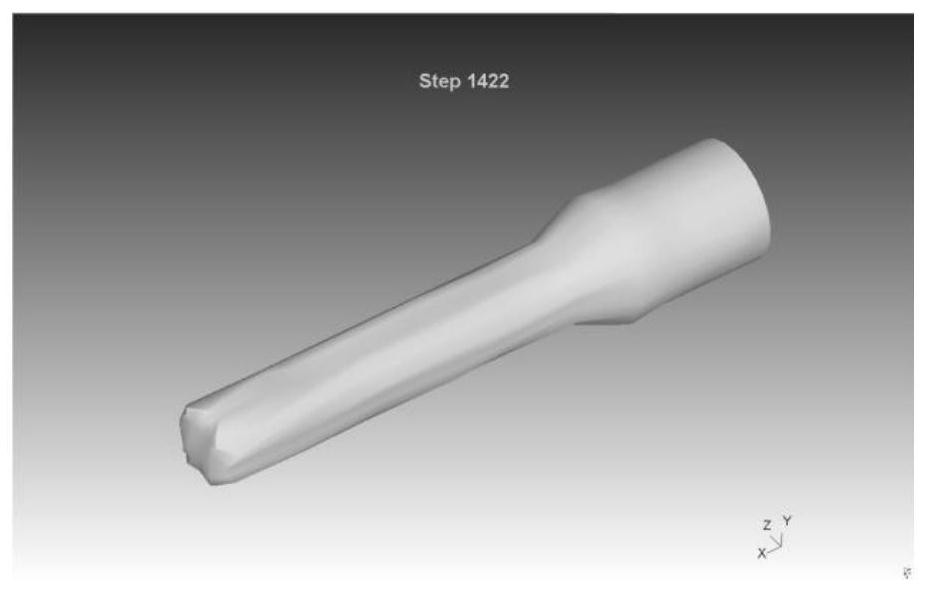

[0029] combine Figure 3-Figure 11 Explain, a kind of robot intelligent free forging drawing length method that can be suitable for shaft forging, it comprises the following steps:

[0030] 1. Finite element simulation. The robot en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com