Non-preheating combined welding method of 1200MPa high-strength steel

A high-strength steel and welding method technology, which is applied in the non-preheating combined welding of high-strength steel with a tensile strength of 1200 MPa and the welding field of high-strength steel, can solve the complex welding process, high production cost, increase construction difficulty and production cost, etc. problems, to avoid tempering softening, good strength and toughness, smooth and beautiful surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

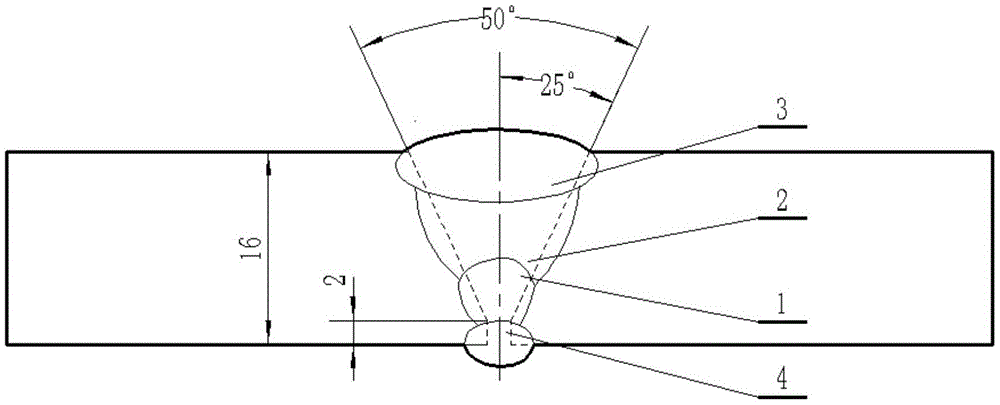

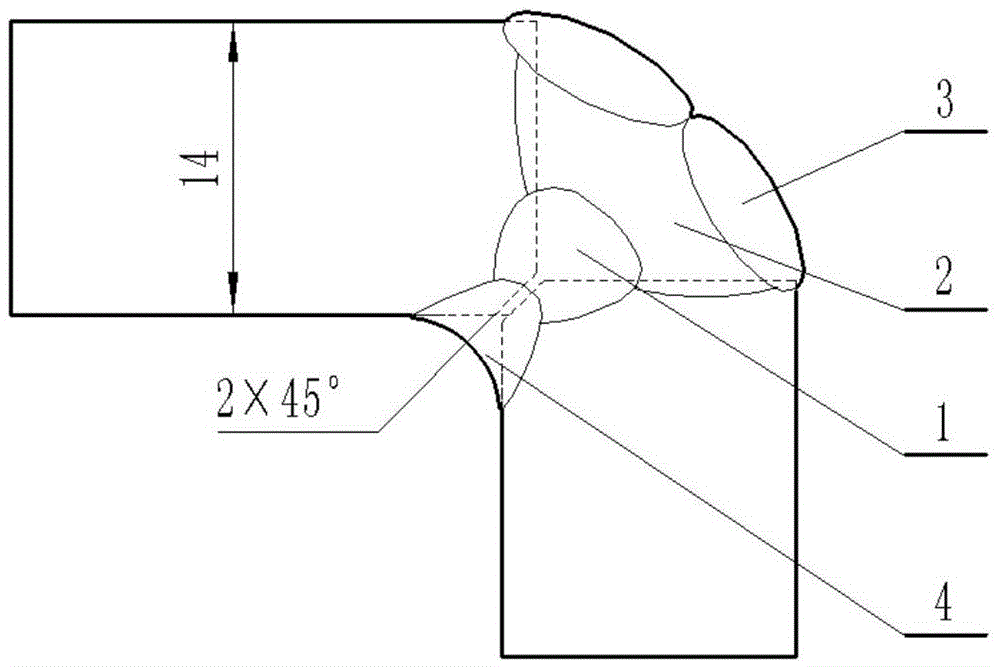

[0048] Butt welding of 1200MPa high-strength wear-resistant steel with a thickness of 16mm. The bottom layer and filling layer are respectively carbon dioxide gas shielded welding filled with 500MPa and 980MPa high-strength steel welding wire, and the cover layer and sealing layer are filled with non-melting electrode argon arc welding filled with 560MPa high-strength steel welding wire. The inverter welding equipment with good dynamic characteristics is selected, and the joint of the welding test plate is milled to open a V-shaped groove with a groove angle of 50° and a blunt edge of 2 mm. Use a manual grinder to grind the rust and oil stains on the surface of the groove and within 20mm on both sides of the welded joint to expose the metallic luster.

[0049] (1) Carbon dioxide gas shielded welding is used as the bottom welding, and the welding material is 500MPa high-strength steel gas shielded welding wire (Korean ZO-26 welding wire). The chemical composition of the deposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com