Aero-engine rectification cover hood anti-icing device adopting loop type heat pipe and anti-icing method of aero-engine rectification cover hood anti-icing device

An aero-engine and anti-icing device technology, which is applied to deicing devices, aircraft parts, transportation and packaging, etc., can solve the problems that aero-engine fairing caps affect the performance of aero-engines, affect the working efficiency of the engine, and endanger the safety of aero-engines, etc. Achieve the effect of light weight, simple structure and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and examples.

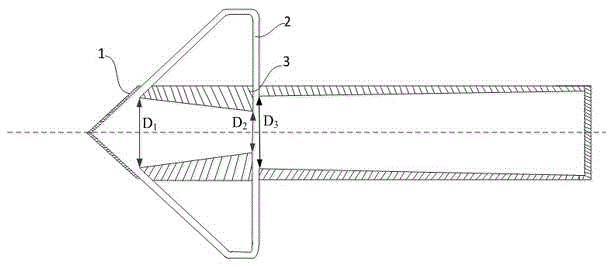

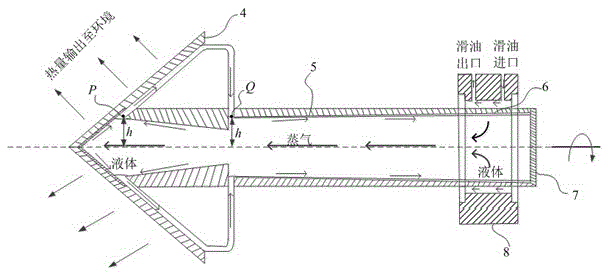

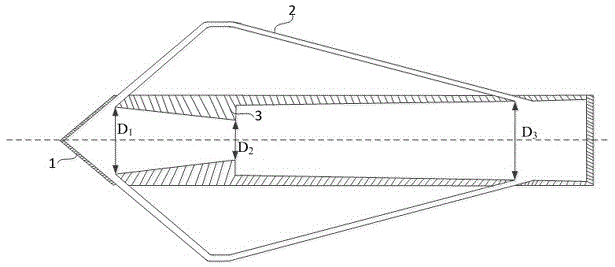

[0020] like figure 1 , 2 As shown, the aeroengine cowling anti-icing device using a loop heat pipe in Embodiment 1 of the present invention includes an axially rotating heat pipe 7 , a lubricating oil jacket 8 and a liquid return channel 2 . The axially rotating heat pipe 7 is provided with a first condensation section 1, a second condensation section 3, an adiabatic section 5, and an evaporation section 6 from front to back. The axially rotating heat pipe 7 rotates around the central axis under the drive of external force. Tube walls are made of pure copper.

[0021] The lubricating oil sleeve 8 is installed on the evaporation section 6 of the axially rotating heat pipe 7. There is a lubricating oil circulation channel in the lubricating oil sleeve 8. The inlet and outlet of the circulating channel are connected to the engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com