A textile unwinding mechanism

A technology of flat plate and rolling roller, which is applied in the textile field, can solve the problems of not being able to adapt to the use of various textile yarns, the yarn tension cannot be adjusted, and the unfavorable use range, etc., to achieve good promotion and utilization value, maintain consistency, and adjust yarns tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

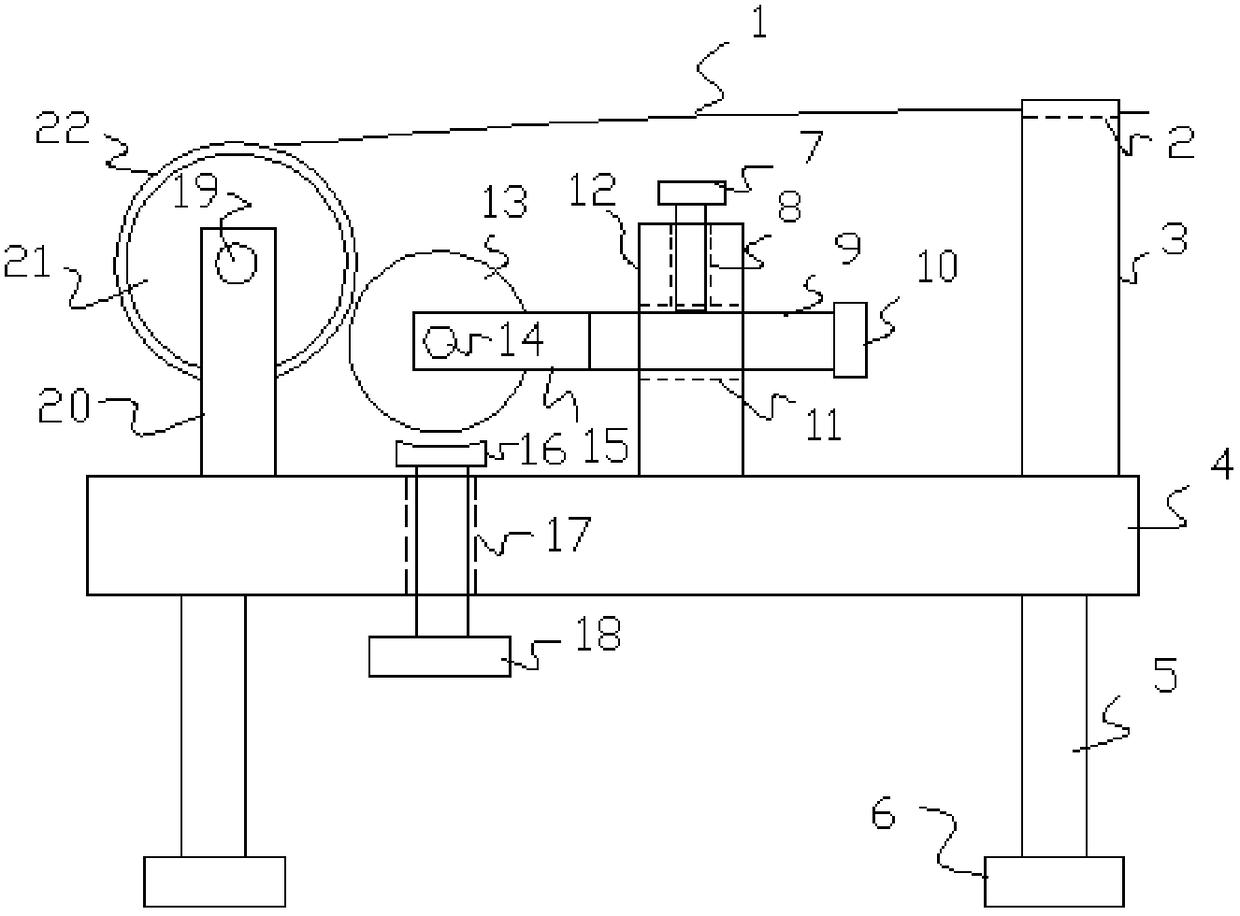

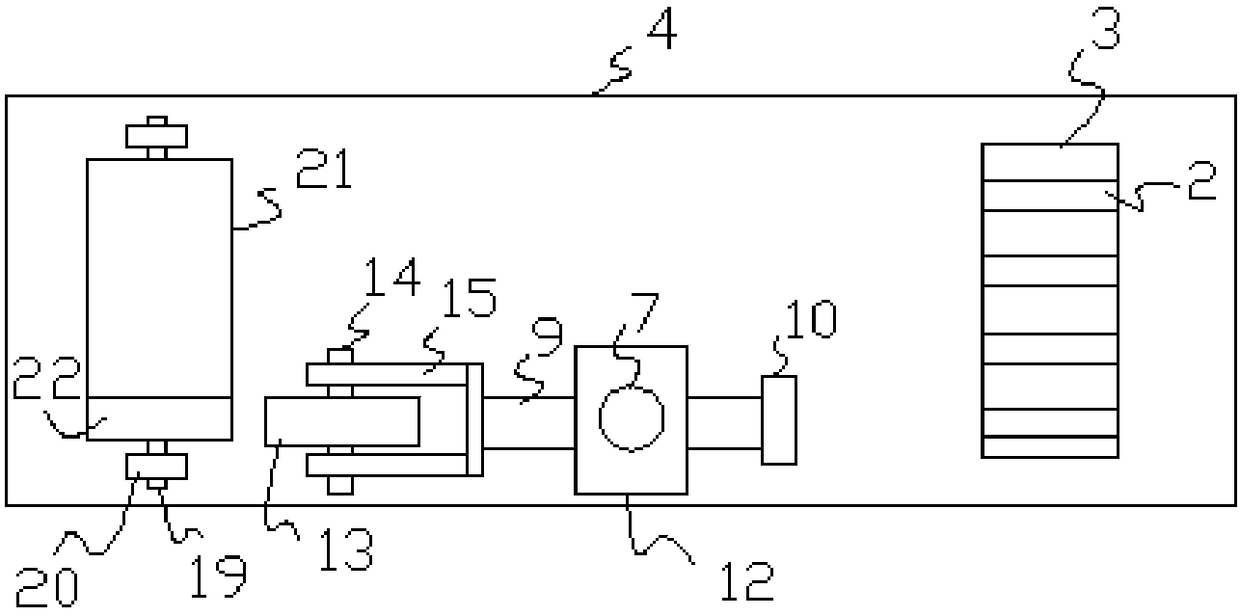

[0022] Such as figure 1 , figure 2 As shown, the structure of this kind of textile unwinding mechanism includes a flat plate 4, the bottom of the flat plate 4 is provided with a leg 5; the left end of the upper surface of the flat plate 4 is provided with a roll 21 through a bracket 20, and The winding roller 21 is wound with the yarn 1 , and a rubber sleeve 22 is fixedly arranged on the outer surface of one end of the winding roller 21 .

[0023] In the above-mentioned embodiment, specifically, a rubber roller 13 is provided on the lower right side of the rolling roller 21 through a U-shaped bracket 15, and the U-shaped bracket 15 is connected with a horizontal support rod 9, and the described support rod The rod 9 passes through a support 12 vertically fixed on the upper surface of the plate 4 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com