A kind of high-texture carbon-based composite material and preparation method thereof

A composite material and high-texture technology, which is applied in the field of high-texture carbon-based composite materials and preparation, can solve the problems of difficult preparation of high-textured pyrolytic carbon, high degree of pyrolytic carbon texture, and shortened preparation cycle. Achieve the effect of shortening the preparation cycle, excellent performance and improving the degree of texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

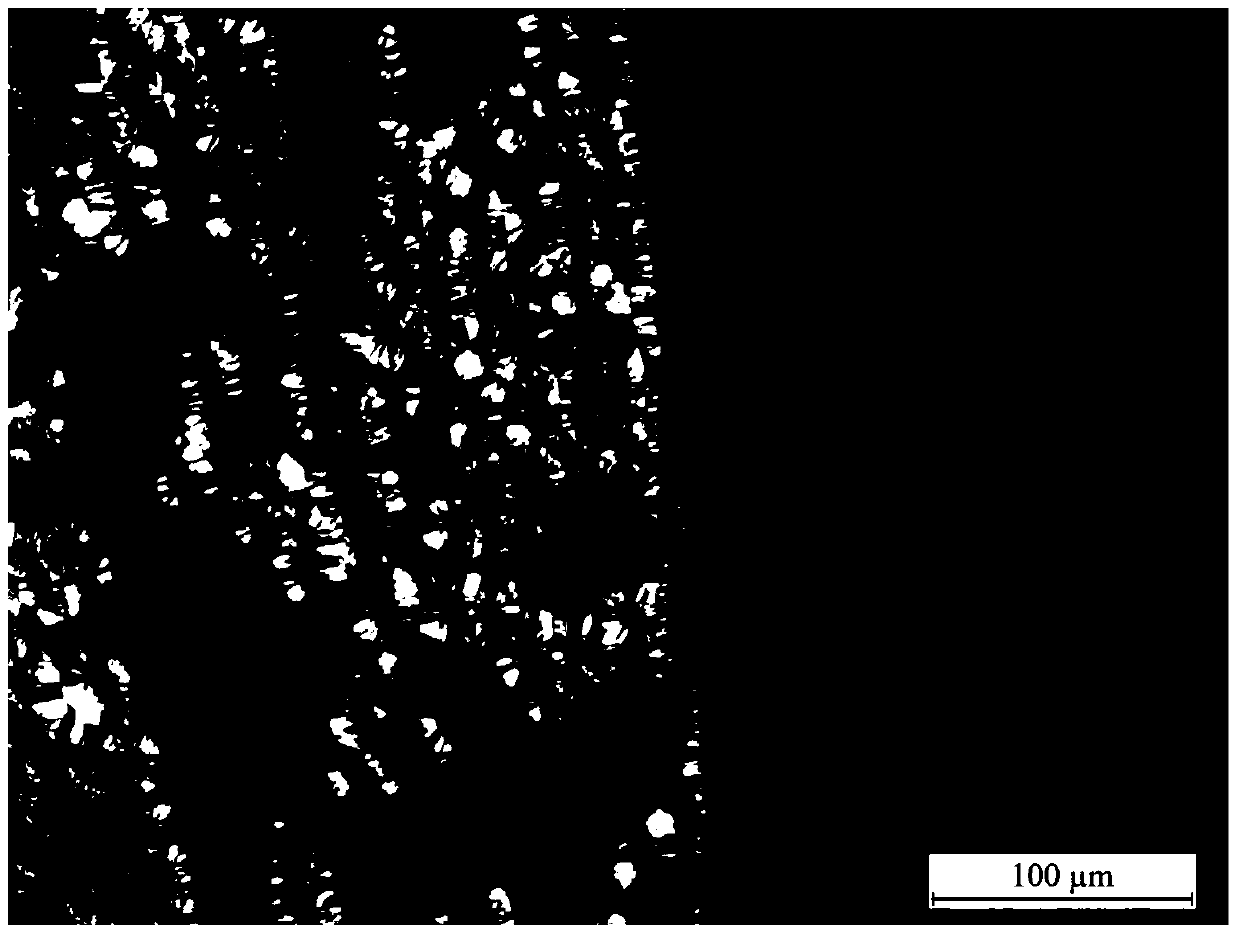

Image

Examples

preparation example Construction

[0027] The preparation method of this composite material comprises the following steps:

[0028] (1) Carbonization: Carbonize the prefabricated body prepared by PAN-based pre-oxidized wire in a high-temperature furnace, using argon as the protective atmosphere, where the argon pressure is 10-50kPa, the flow rate is 100L / h, and the carbonization temperature is 900-1300 °C, the carbonization time is 10-50 hours, and the volume fraction of fibers in the preform after carbonization is 30-40%.

[0029] (2) Graphitization: graphitize the carbonized preform in a high-temperature furnace with argon as a protective atmosphere at a temperature of 1600-2300° C. for 5-50 hours, and the pressure of the argon at 5-20 kPa.

[0030] (3) Densification: place the graphitized preform in a CVI vapor deposition furnace, use nitrogen as a protective atmosphere, evacuate to below 100pa, and raise the temperature at a constant rate of 100-200°C / h. When the CVI vapor deposition furnace When the tempe...

Embodiment 1

[0037] Take the prefabricated body made of domestic PAN-based pre-oxidized wire as an example.

[0038] (1) Carbonization: Carbonize the prefabricated body prepared by domestic PAN-based pre-oxidized wire in a high-temperature furnace, using argon as the protective atmosphere, in which the flow rate of argon gas is 100L / h, the pressure is 50kPa, and the carbonization temperature is 1100°C. The time is 20 hours, and the prefabricated fibers account for 40% of the volume fraction of the prefabricated body after carbonization.

[0039] (2) Graphitization: graphitize the carbonized preform in a high-temperature furnace with argon as a protective atmosphere at a temperature of 2300° C. for 15 hours, and the pressure of argon at 10 kPa.

[0040](3) Densification: Place the prefabricated body in a CVI vapor deposition furnace, use nitrogen as a protective atmosphere, evacuate to below 100pa, and raise the temperature at a constant rate of 200°C / h. When the temperature in the CVI vapo...

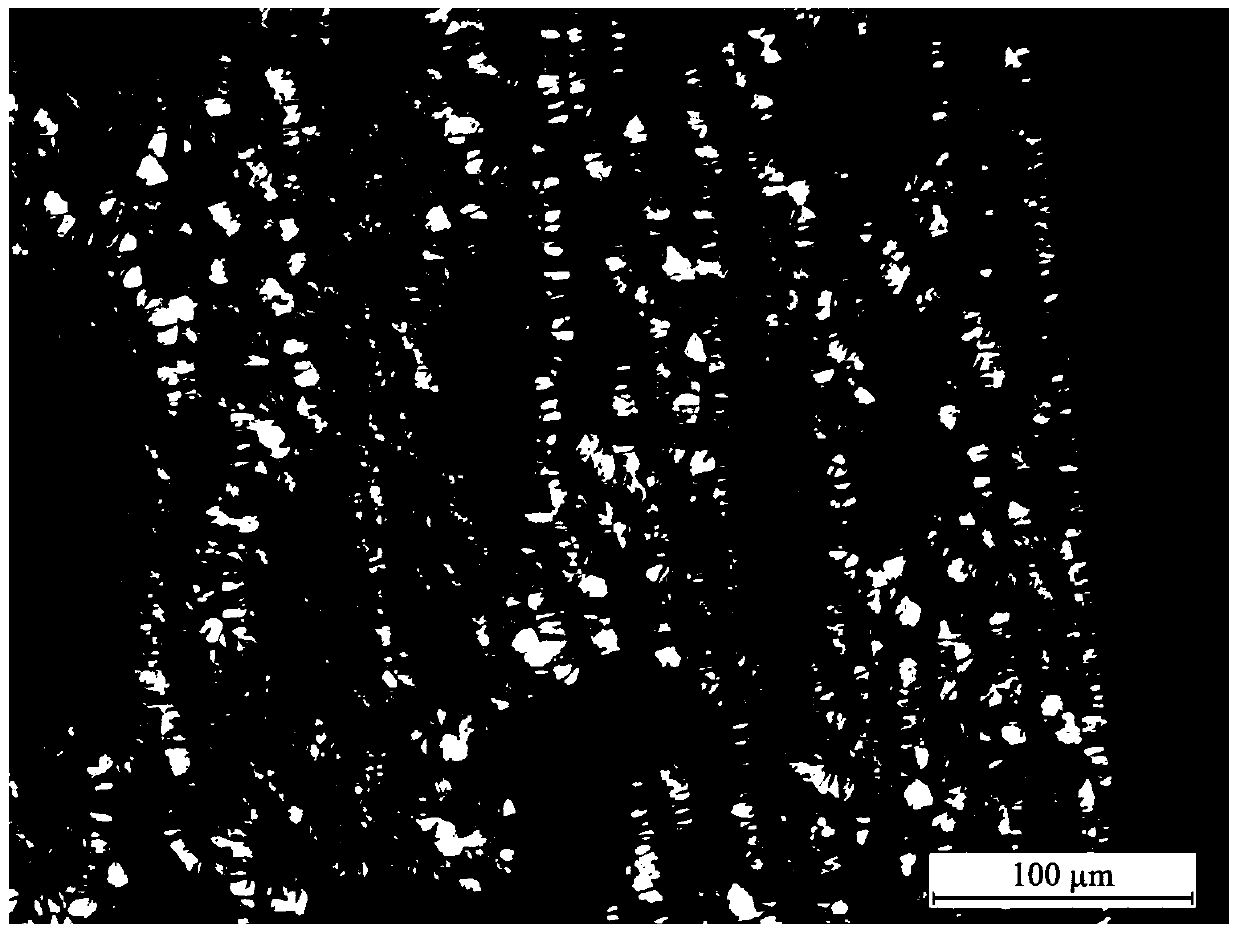

Embodiment 2

[0047] (1) Carbonization: Carbonize the domestic PAN-based pre-oxidized wire preform in a high-temperature furnace, using argon as the protective atmosphere, in which the argon flow rate is 100L / h, the air pressure is 10kPa, the carbonization temperature is 1200°C, and the carbonization time is 35h, the preform volume fraction after carbonization is 35%.

[0048] (2) Graphitization: graphitize the carbonized preform in a high-temperature furnace, using argon as a protective atmosphere at a temperature of 2100° C. for 20 hours, and the pressure of the argon at 20 kPa.

[0049] (3) Densification: Place the preform in a CVI vapor deposition furnace, use nitrogen as a protective atmosphere, evacuate to below 100pa, and raise the temperature at a constant rate of 150°C / h. When the temperature in the CVI vapor deposition furnace rises to 1100°C At this time, the methane and ethylene are respectively fed into the CVI vapor deposition furnace with a flow meter, the liquid naphthalene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com