A beam-column steel tube structure

A steel tube and column tube technology, which is applied in the field of high-rise building engineering, can solve the problems of high performance requirements and large bearing capacity of the beam-column structure of the core tube, and achieve the effects of excellent seismic resistance, good sightlines, and favorable structural stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

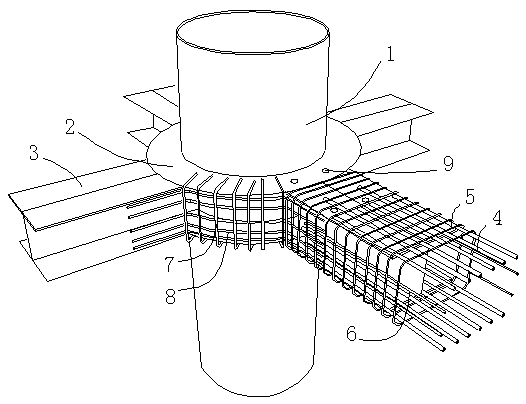

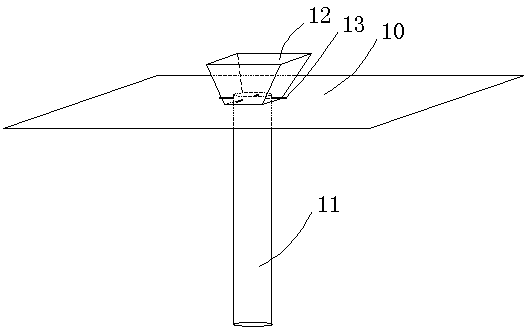

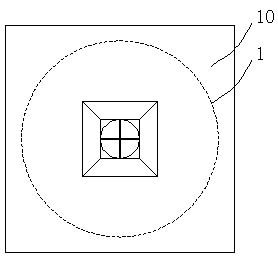

[0030] The present invention will be described in further detail below in conjunction with a kind of construction method and accompanying drawings of the high-rise building core tube beam-column structure of the present invention.

[0031] An optimal implementation mode of the construction method of the core tube beam-column structure of a high-rise building. The construction method includes the steps of completing the construction of the column foot of the steel pipe column. Each section constitutes a multi-section single-layer steel pipe column, and the construction of each single-layer steel pipe column is completed sequentially from bottom to top. During the construction of each section of single-layer steel pipe column, a steel pipe column with a corbel foundation is used outside and the upper part of the steel pipe column on this layer is completed. Construction of the legs.

[0032] In this way, during the construction of the core tube beam-column structure of high-rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com