Block-distributed 3D printing device and printing method thereof

A 3D printing and printing device technology, applied in construction, additive processing, building construction, etc., can solve the problems of not being able to meet the construction needs of large-scale buildings, shortening the length of a single printing head beam, and low working efficiency of a single printing head. , to achieve the effect of reducing the printing range, improving printing efficiency and preventing vertical displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

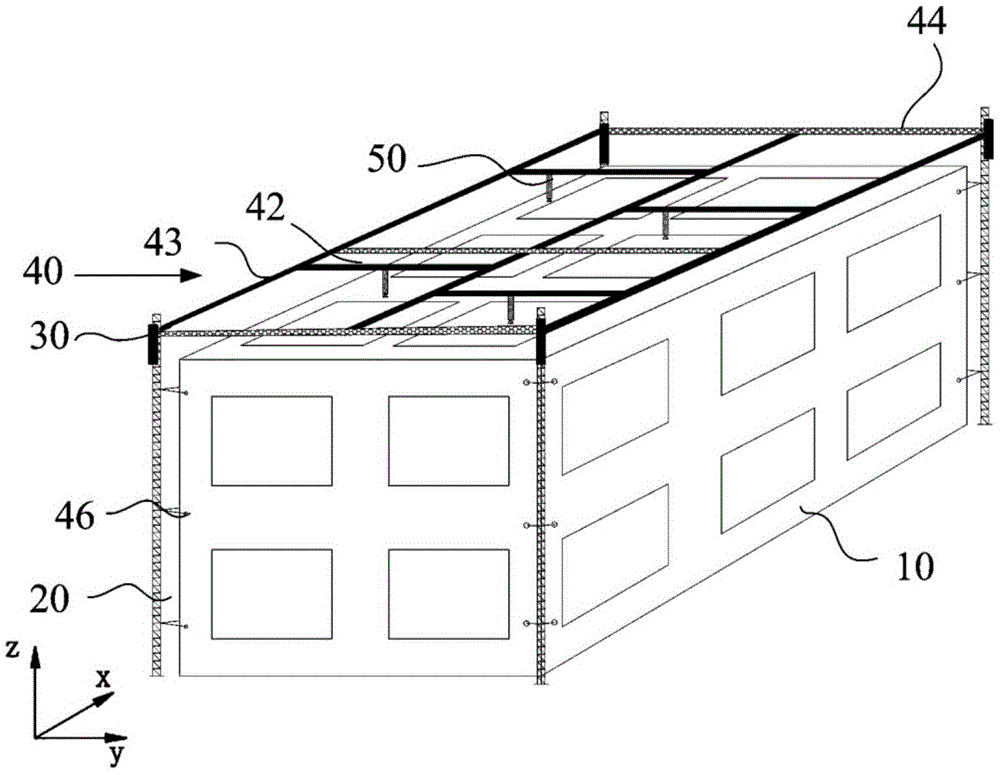

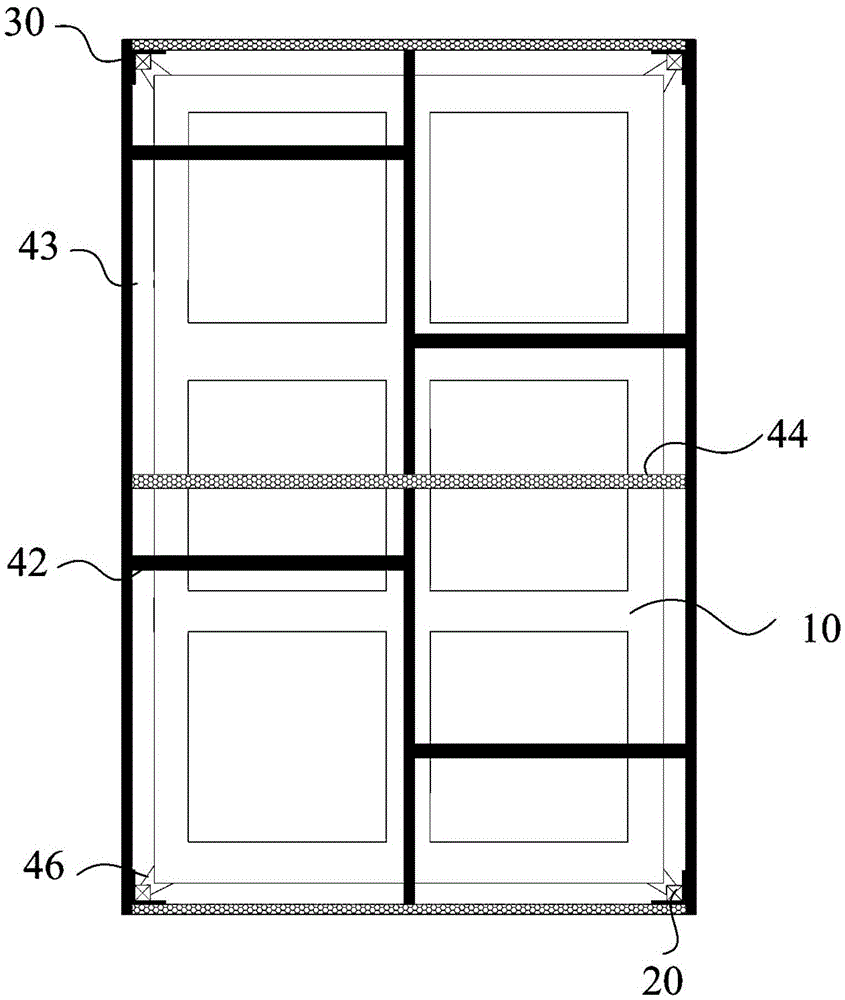

[0028] combine Figure 1 to Figure 4 To illustrate the block-distributed 3D printing device of the present invention, this embodiment takes the 3D printing construction of a large-scale building as an example. In order to clarify the direction relationship, the z-axis direction is set as the height extension direction of the printed building body 10 as required. xyz Cartesian coordinate system.

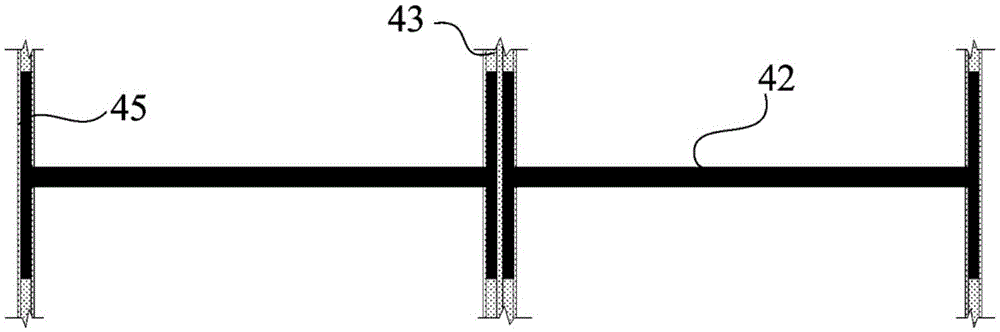

[0029] Please refer to Figure 1 to Figure 4 The above block distributed 3D printing device includes a climbing rail 20 fixed on the facade of the printed building 10, a climbing member 30 that can climb or descend relative to the printed building 10 along the climbing rail 20, and a Print the top of building body 10, and the printing device 40 that is rigidly connected with climbing member 30; The track beam 43 and the grid formed by the connecting beam 44 are connected. The track beam 43 and the connecting beam 44 are respectively parallel and equally spaced. The track beam 43 on...

Embodiment 2

[0038] combine Figure 1 to Figure 4 To illustrate the printing method of the block distributed 3D printing device of the present invention, this embodiment takes the construction of a building with an elevation above ±0.000 as an example, and the specific steps are as follows:

[0039] S001: Install a block-distributed 3D printing device so that the track frame is stably attached to the facade of the printed building 10, so that the printing head 50 of the printing device 40 is located at an appropriate height above the printed building 10 and at the initial position;

[0040] S002: Send a control command to the printing device 40 through the power control system, so that each print head 50 moves along the corresponding print head beam 42, and ejects building materials at the same time. Every time the print head 50 prints a line, the print head beam 50 moves along the slideway 1. Set the distance, and repeat in this way to complete the printing construction of the current cro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap