Speed-increasing impeller for wind power generation

A technology for impellers and blades, which is applied in the field of speed-increasing impellers for wind power generation. It can solve the problems of rapid rotation of the blades, large centrifugal force, lower safety factor of the whole machine operation, and prone to speeding phenomenon, etc., so as to improve work efficiency, reduce system errors, and The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

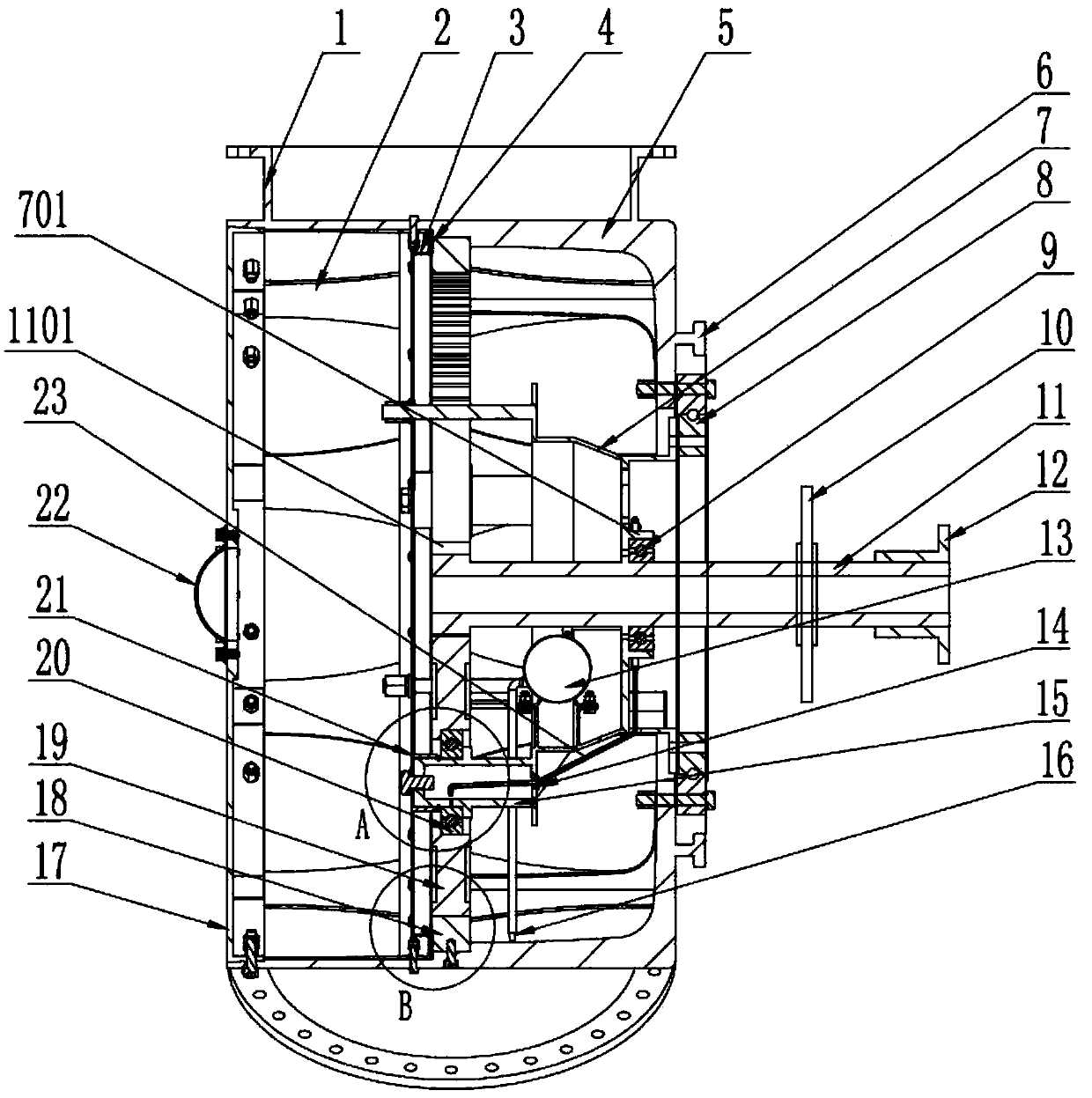

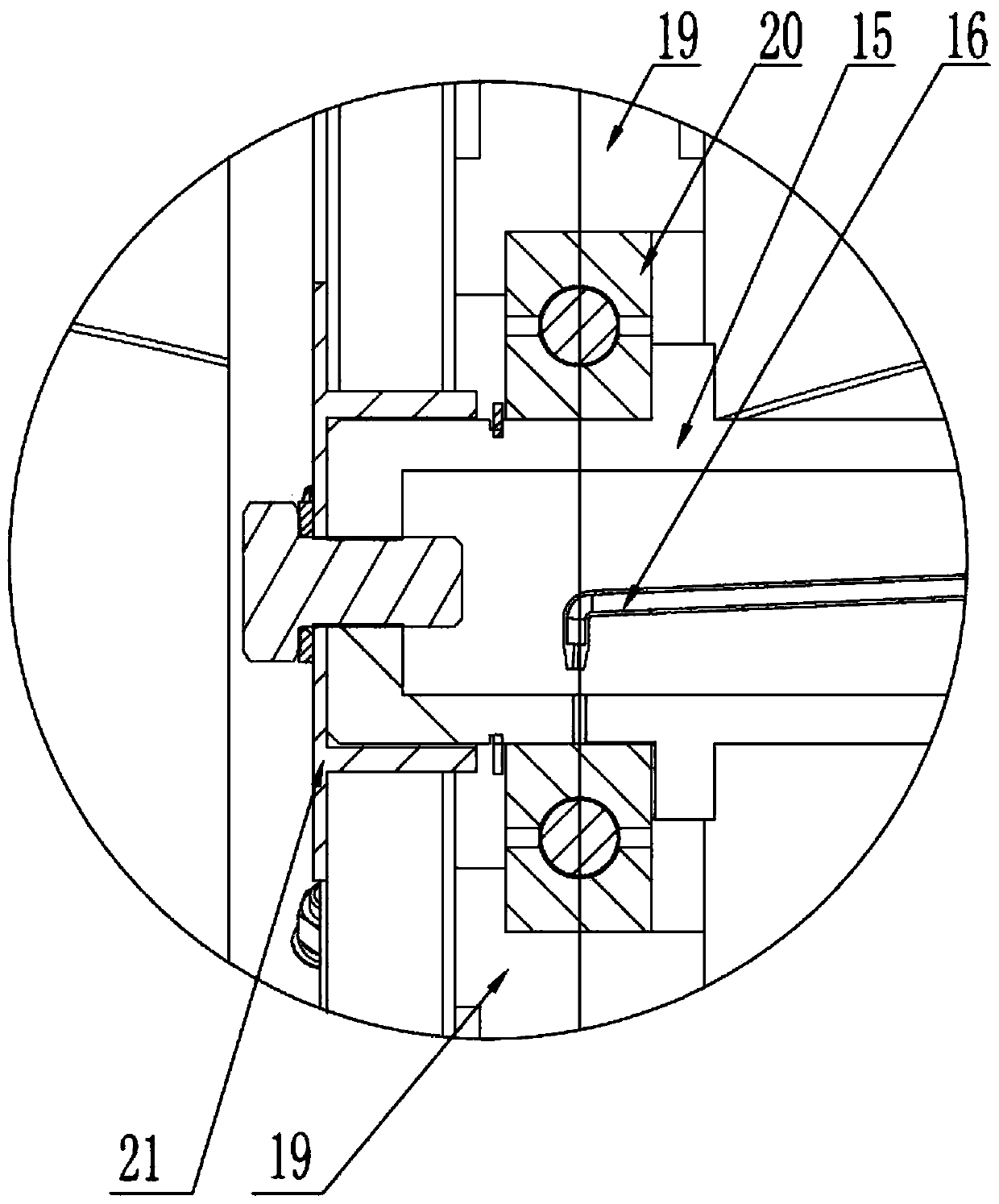

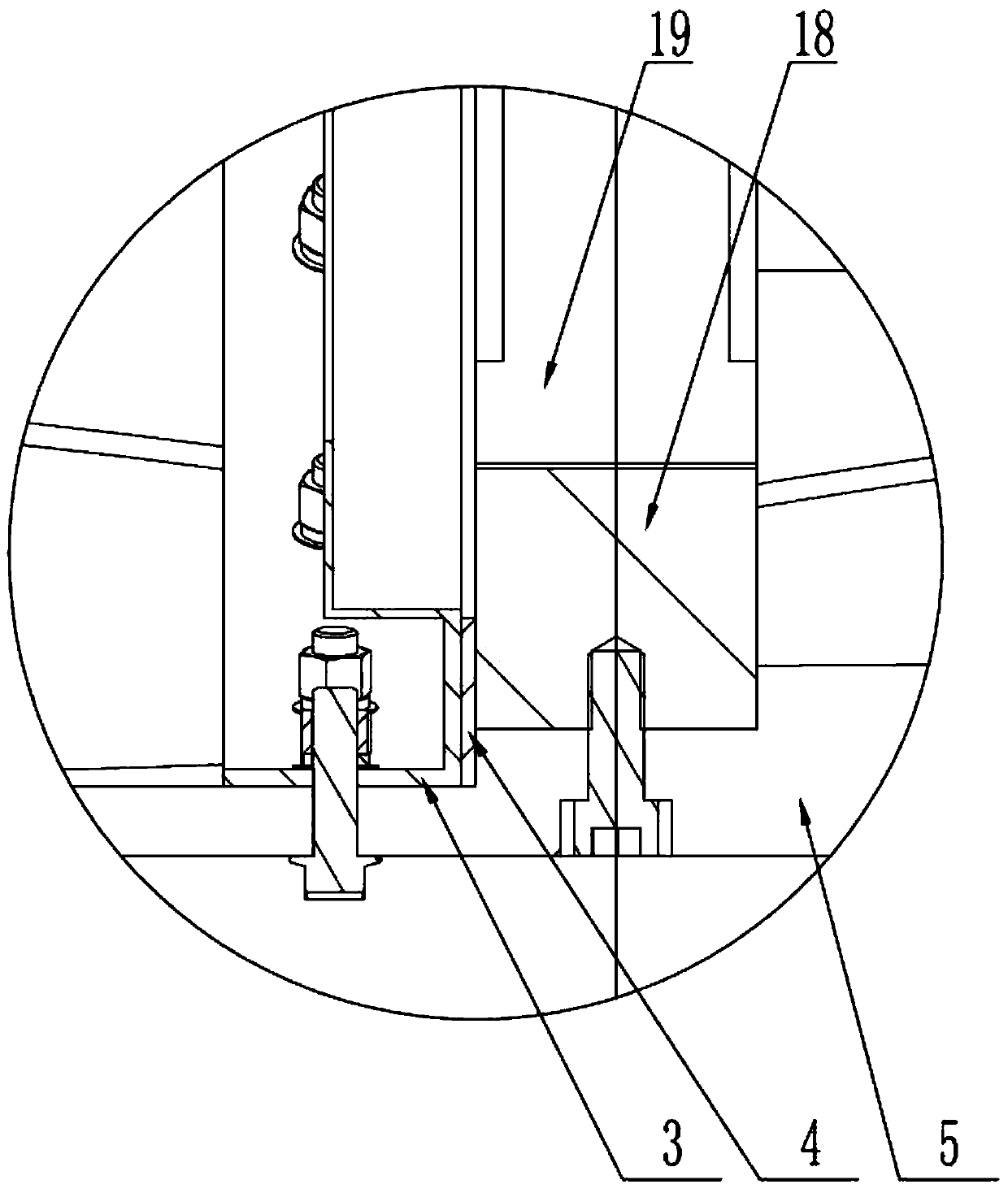

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a speed-increasing impeller for wind power generation includes an impeller cylinder 5, a plurality of blade bases 1 for connecting blades are evenly distributed on the outer wall of the impeller cylinder 5, and a ring gear 18 is fixed on the inner wall of the impeller cylinder 5 , a plurality of planetary gears 19 are meshed with the inner ring of the ring gear 18, and each planetary gear 19 is meshed with the sun gear 1101; the center of each planetary gear 19 is fitted with the planetary shaft 15, and the outer ring of each planetary shaft 15 is fitted with In the second bearing 20, one end of each planet wheel shaft 15 is connected to one end of the planetary carrier 7 to form a whole, the other end of the planetary carrier 7 is matched with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com