Chicken roasting frame

A roast chicken rack and a pair of technology, applied in the field of roast chicken racks, can solve the problems of insufficient positioning of roast chickens, difficulty in ensuring uniform heating, and affecting the quality of roast chickens, and achieve sufficient and uniform heating, simple structure, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

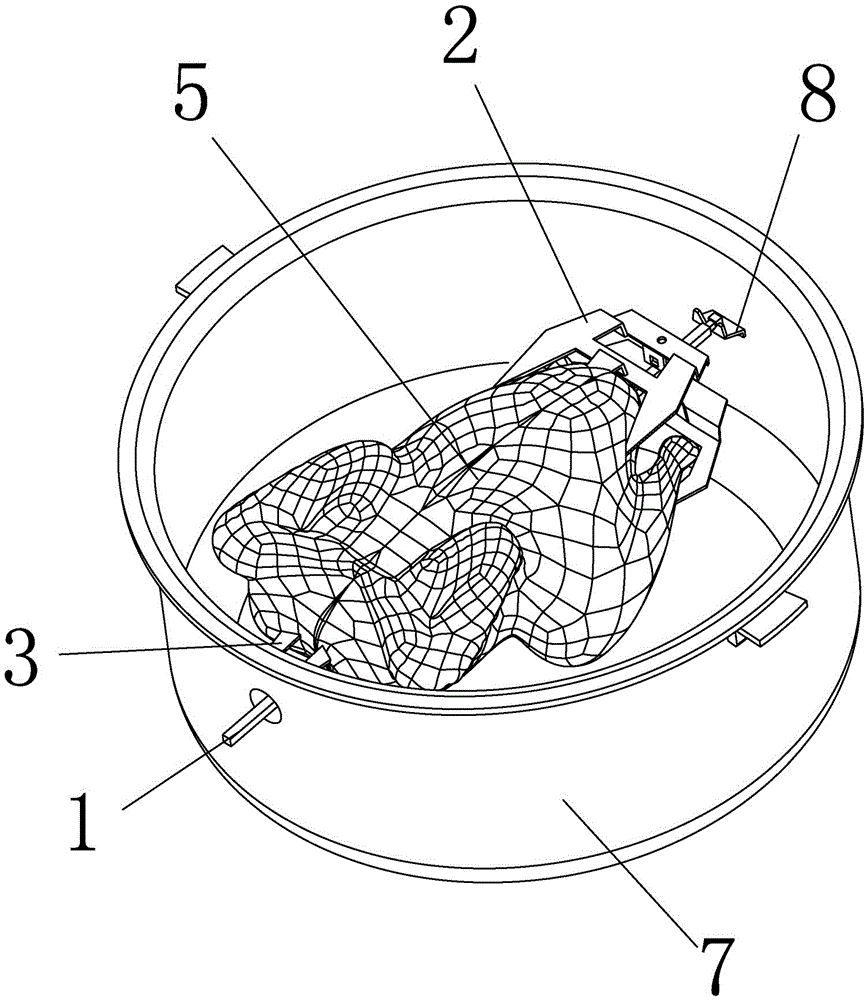

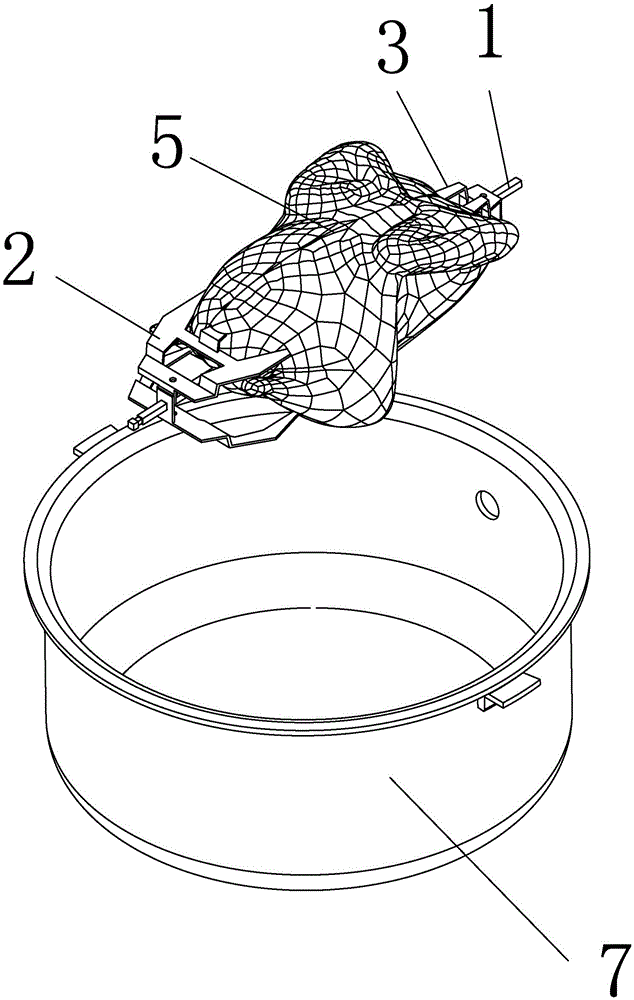

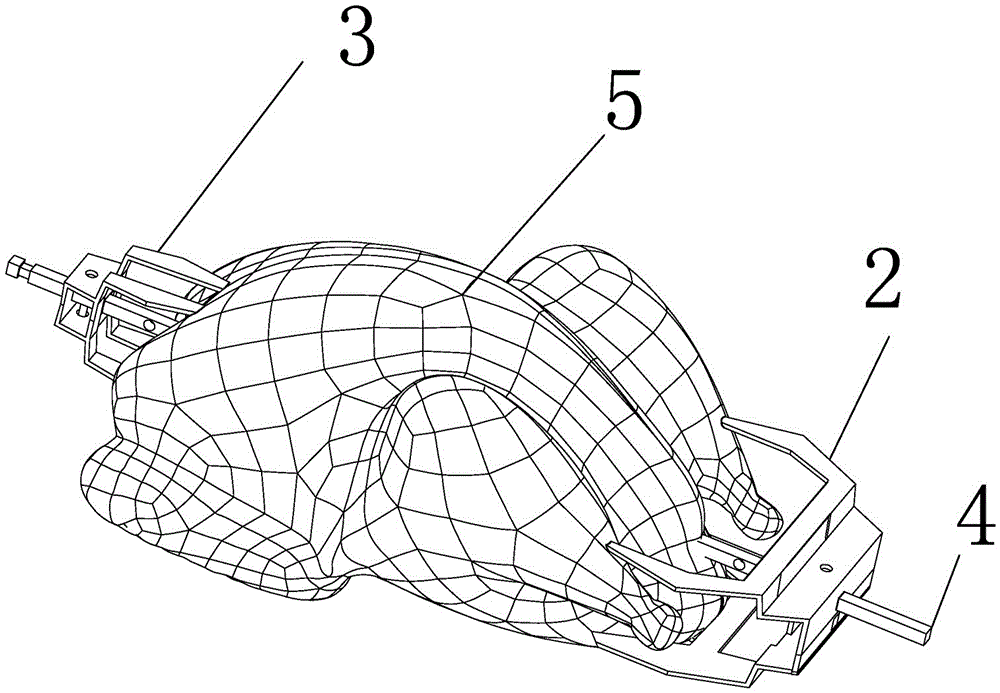

[0022] Hereinafter, the present invention will be further explained in detail with reference to the drawings. A grilling chicken rack, which is characterized in that it includes a rotating rod 1 and a main positioning rack 2 and a secondary positioning rack 3 detachably mounted on it. The two positioning racks are installed oppositely and fixed to the upper rotating rod by a locking device 4 1. Roast chicken 5 is clamped and fixed between two positioning frames:

[0023] The main positioning frame 2 includes a main support plate 21 connected with the rotating rod 1 and a pair of chicken leg fixing forks 22 and a pair of chicken hip fixing forks 23 distributed up and down on it;

[0024] The auxiliary positioning frame 3 includes an auxiliary supporting plate 31 connected with the rotating rod 1, and a pair of chicken breast fixing forks 32 and a pair of chicken back fixing forks 33 distributed on it.

[0025] A chicken hip tip fixing fork 24 is provided between the chicken hip fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com