Finned heat exchange tube

A technology of heat exchange tubes and fins, which is applied in the field of vaporizers, can solve the problem that the fin heat exchange tubes and the fin heat exchange tubes cannot be installed with connecting pieces, the installation stability of the fin heat exchange tubes is poor, and the overall heat transfer efficiency is low. problem, to achieve the effect of simple structure, consistent thermal expansion, and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

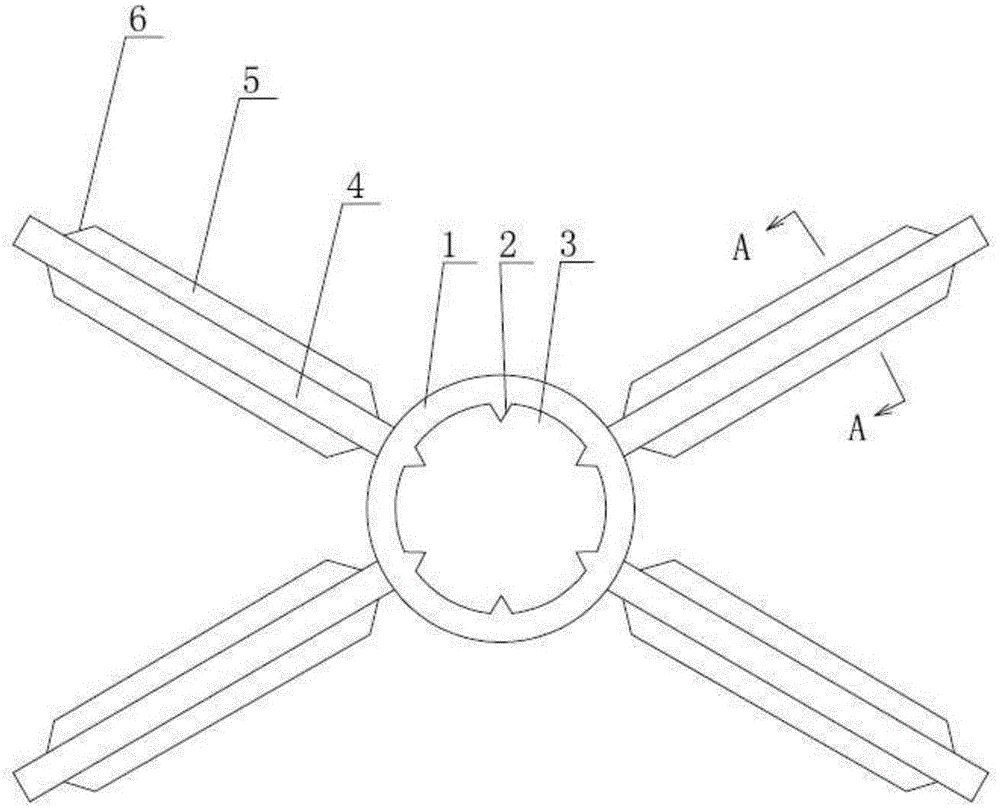

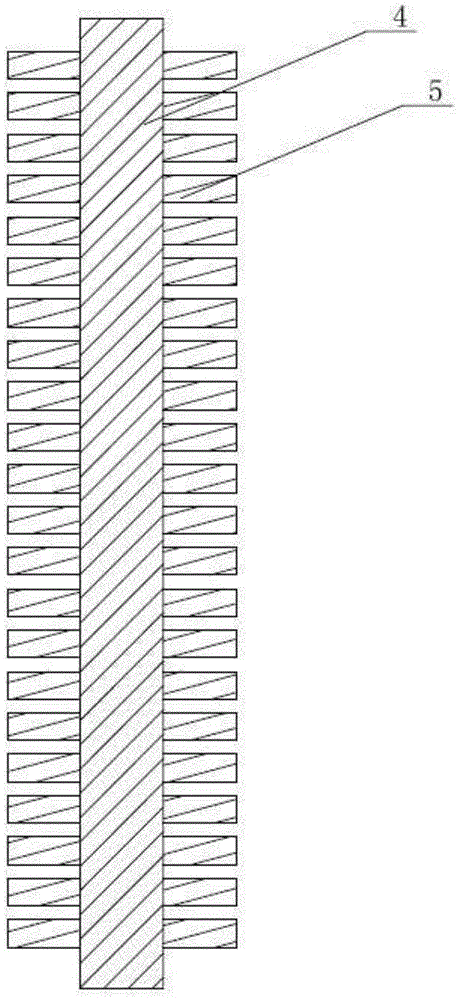

[0015] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0016] like figure 1 , figure 2 As shown, the finned heat exchange tube includes a tube body 1 with an inner hole, the tube body 1 is made of an aluminum alloy material, and a plurality of tapered portions 2 are formed on the inner hole wall of the tube body 1 along the circumferential direction, each tapered portion 2 A semicircular groove 3 is formed therebetween; a plurality of fins 4 are also arranged on the outer circumference of the tube body 1 , and a plurality of thermally conductive sheets 5 are respectively connected to both sides of the fins 5 . The tapered portions 2 are evenly arranged with the center of the tube body 1 as the center. The fins 4 are connected with the tube body 1 to form an "X" shape. The adjacent heat-conducting sheets 5 are arranged in parallel with each other, and the top and bottom surfaces of the heat-conducting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com