Method for measuring spherical object geometric parameters by use of laser and monocular camera

A technology of geometric parameters and lasers, used in measuring devices, optical devices, photogrammetry/video surveying, etc., can solve the problems of inability to measure spherical targets at close range, and inability to accurately measure target positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

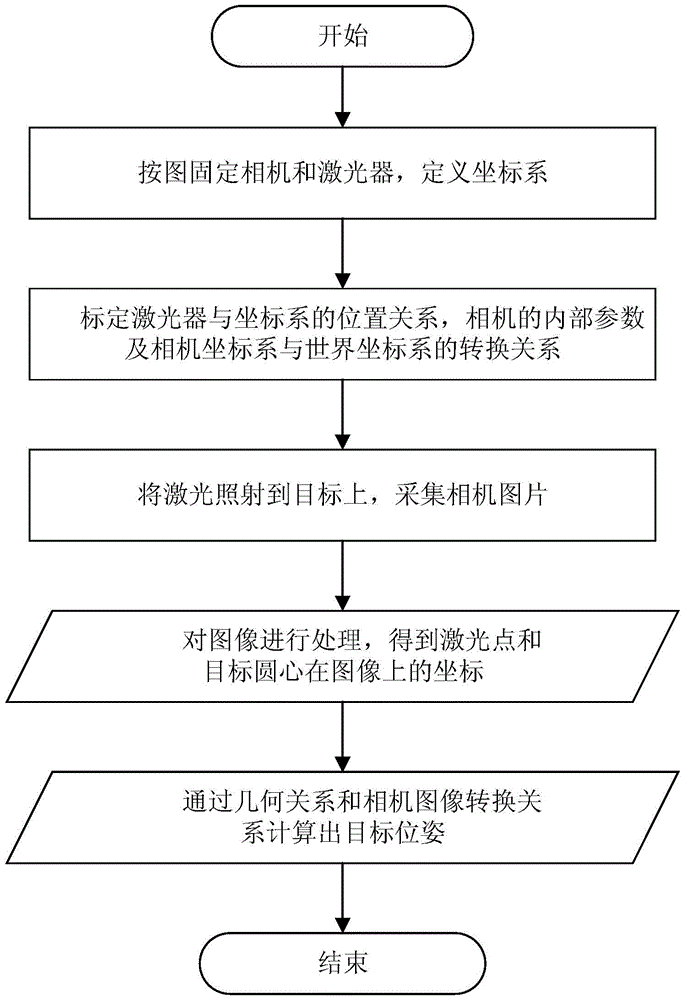

[0037] see figure 1 , the number of lasers used in this embodiment is four, and the implementation steps are as follows:

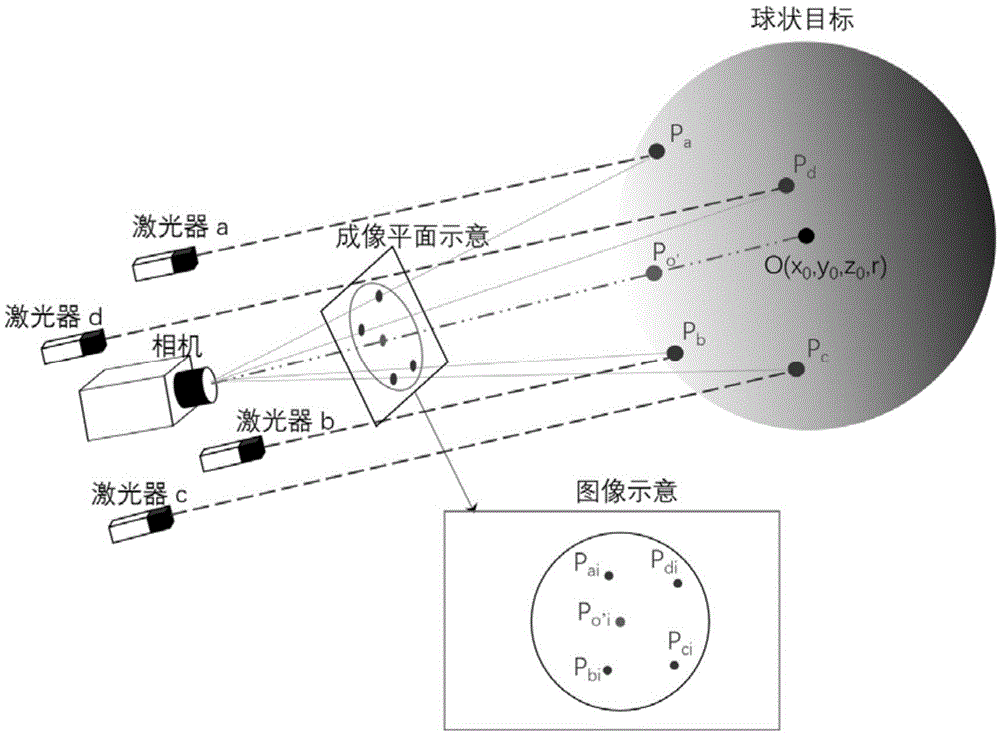

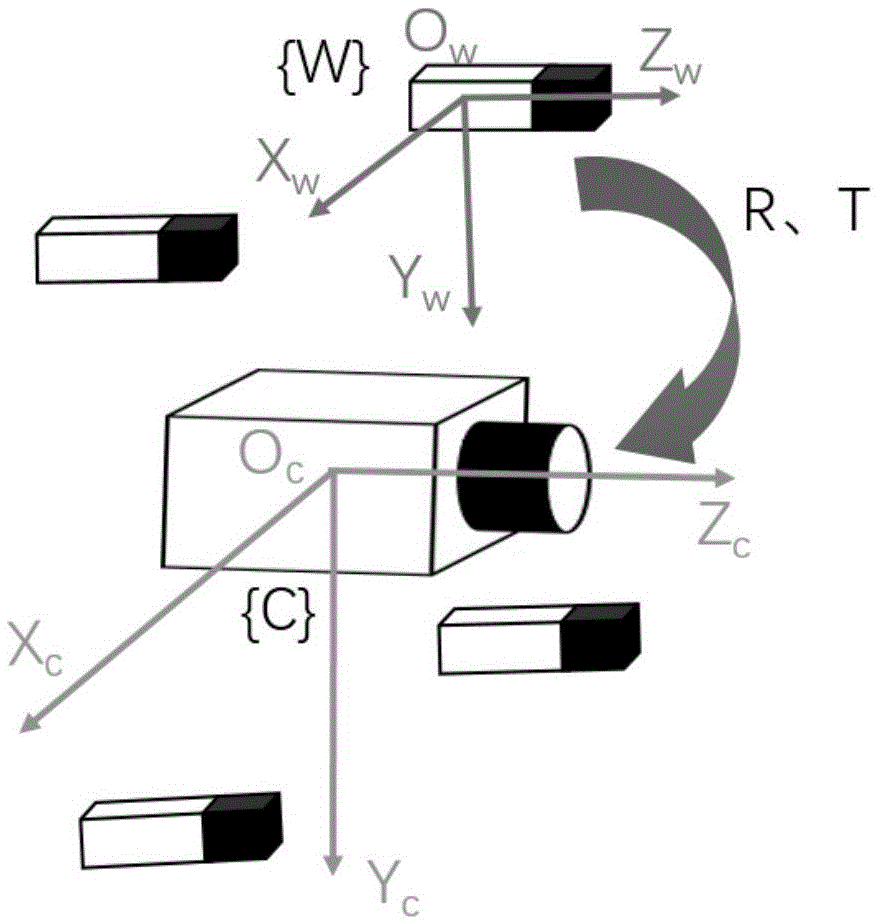

[0038] 1. If figure 2 As shown, the camera and the four lasers are fixed together so that the direction of the laser beams emitted by the four lasers is roughly the same as that of the camera, and every three laser beams are not coplanar. The direction of the beam can be slightly convergent so that the beam can easily irradiate the target. As shown in Figure 3(a), the world coordinate system Ow is defined, and Ow is the right-handed coordinate system. The definition of Ow is determined by the actual application scenario, in order to determine the coordinates of the laser and the angle between the laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com