Glass thickness detection apparatus and glass thickness detection method

A glass thickness and detection device technology, applied in the field of optical measurement, can solve the problems of difficulty in accurately controlling the relative position, affecting the measurement accuracy, limiting the use range of the detection device, etc., to achieve the effect of improving the accuracy and reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description, for illustrative purposes, many specific details are set forth in order to provide a comprehensive understanding of one or more embodiments. However, it is obvious that these embodiments can also be implemented without these specific details. In other examples, for the convenience of describing one or more embodiments, well-known structures and devices are shown in the form of block diagrams.

[0035] Hereinafter, various embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

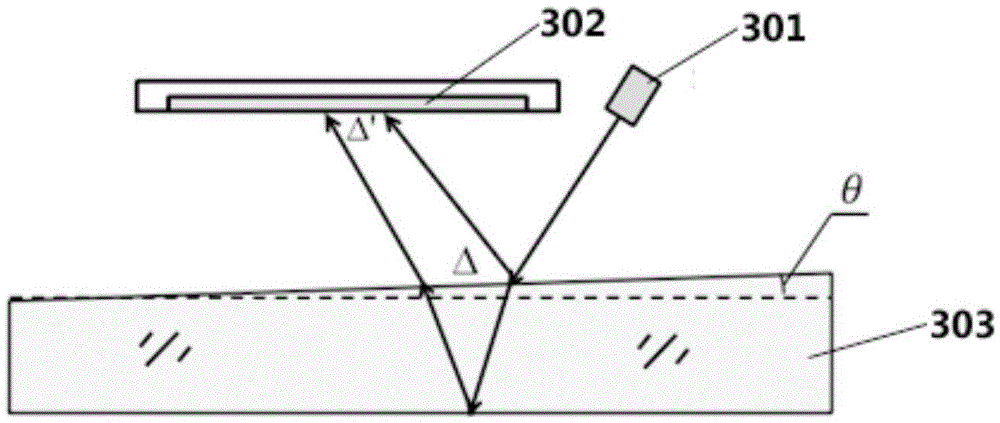

[0036] Figure 4 It is a schematic diagram showing the structure of the glass thickness detection device according to the present invention. Such as Figure 4 As shown, the glass thickness detection device related to the present invention includes: a housing 400 for accommodating various components of the glass thickness inspection device, and has a bottom surface 405 that can contact the surface of the gla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap