A system for fast reactor fuel rods filled with helium plug

A fuel rod and pressing plate technology, applied in the field of reactor engineering, can solve problems such as difficulty in guaranteeing vacuum degree, large glove box space, and affecting plugging quality, and achieve high plugging quality, high plugging efficiency, improved vacuum degree and filling Effect of Helium Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below in combination with the accompanying drawings and specific embodiments.

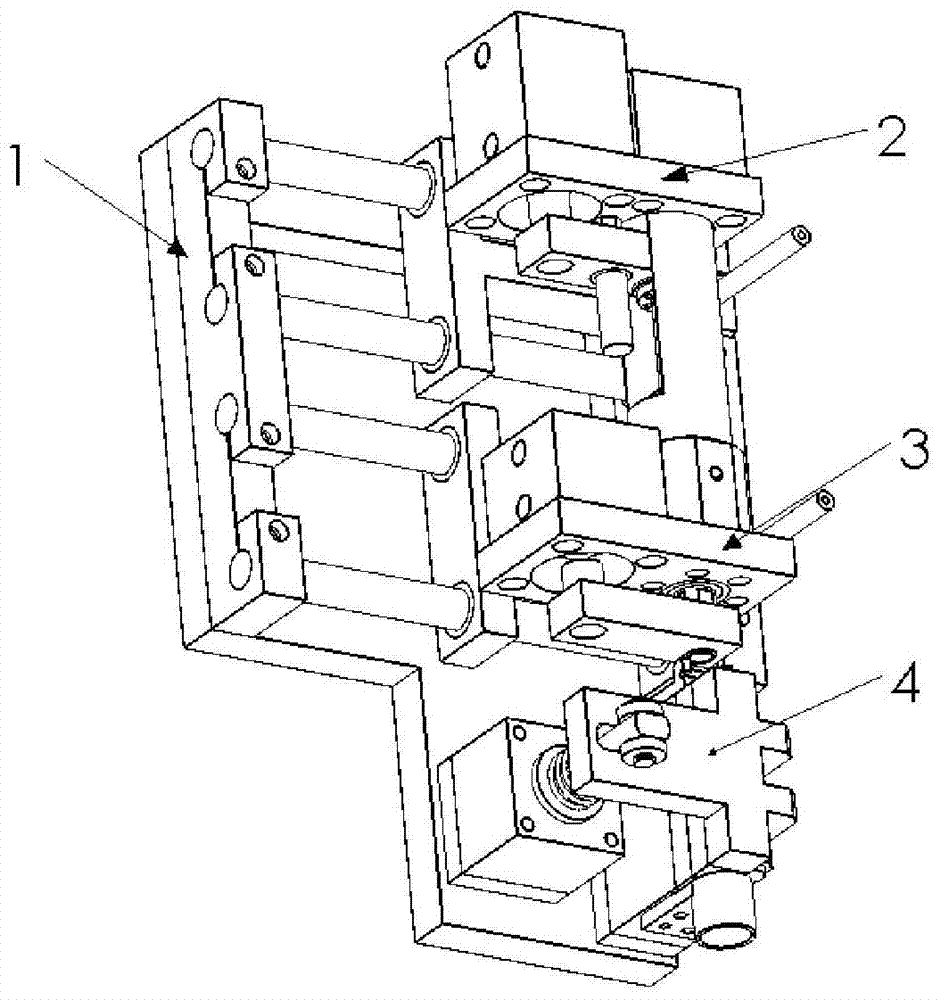

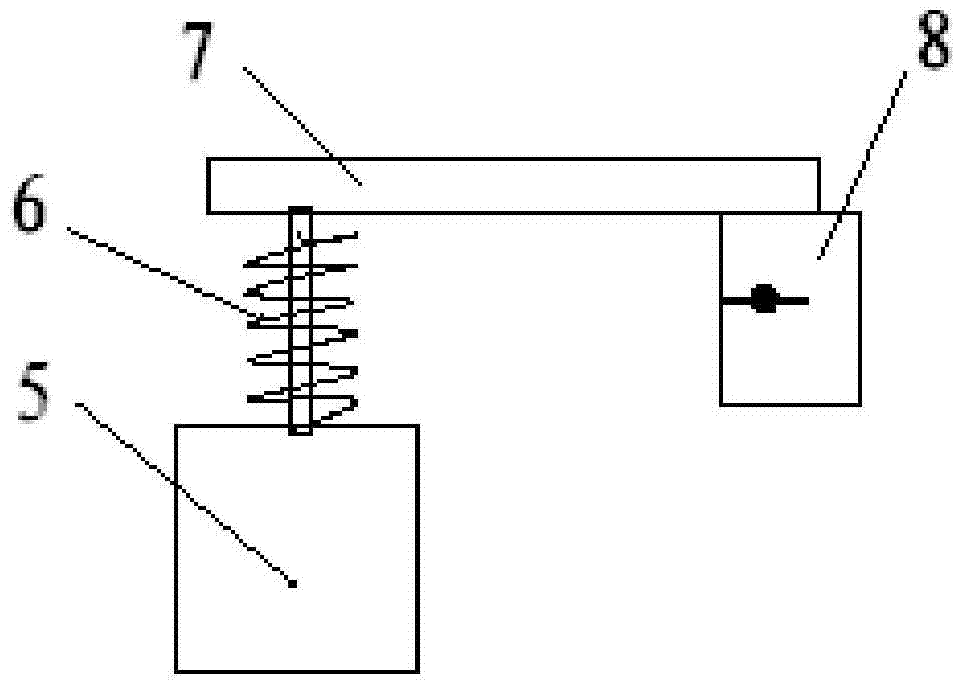

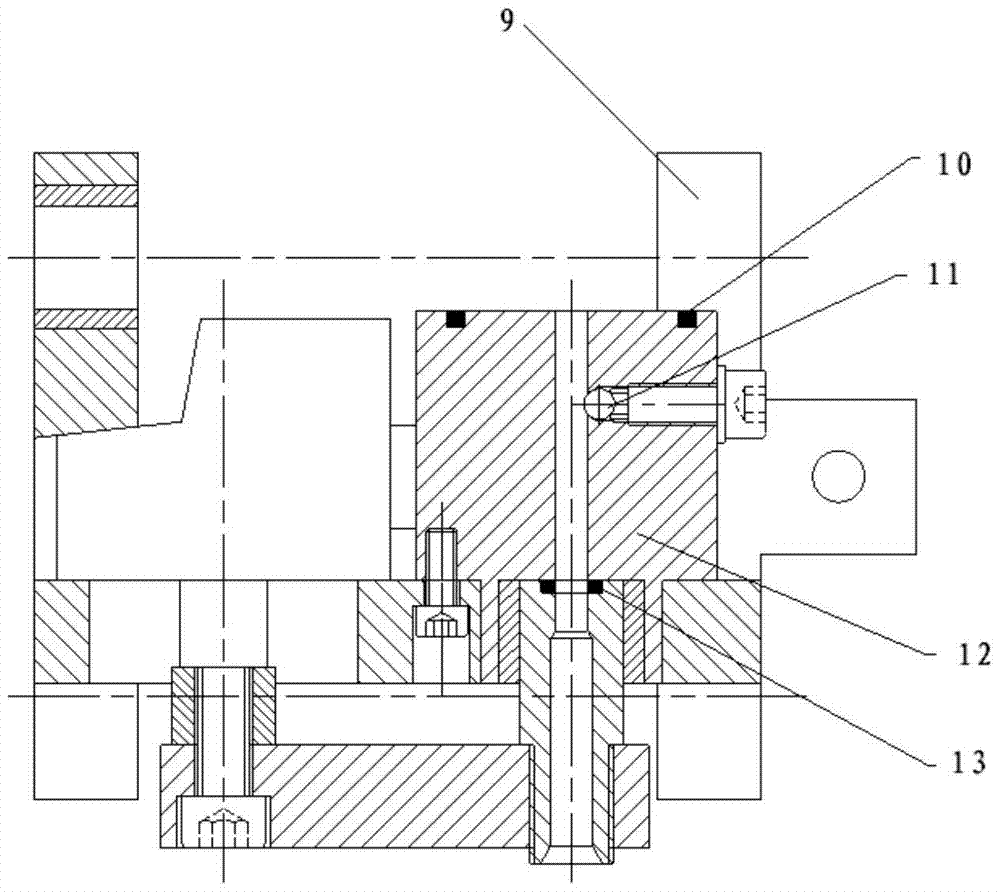

[0033] A system for helium-filled plugging of fast reactor fuel rods, the system includes a frame 1 and a plugging device 2 located on one side of the frame, a sealing device 3 and a clamping device 4; the system is vertically placed in a glove box Inside, the plugging device 2 is located above the sealing device 3, and the sealing device 3 is located above the clamping device 4; the system uses a cylinder as a power source, and manually assists in filling the cladding tube with helium and plugging;

[0034] The frame 1 is made of stainless steel, and a guide shaft is installed on the frame 1, and the guide shaft is convenient for the plugging device 2 and the sealing device 3 to slide horizontally on the guide shaft. The frame 1 is equipped with a limiting device for limiting the plugging device and the sealing device.

[0035] The clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com