Keyboard with hollowed keys and elastic silicone gel bodies

A silicon gel and button technology, applied in layers, electrical components, electric switches, etc., can solve the problems of easy deformation, wear, and difficult quality control of soft rubber, and achieve enhanced pressing feel and accuracy, enhanced backlight effect, and simple assembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

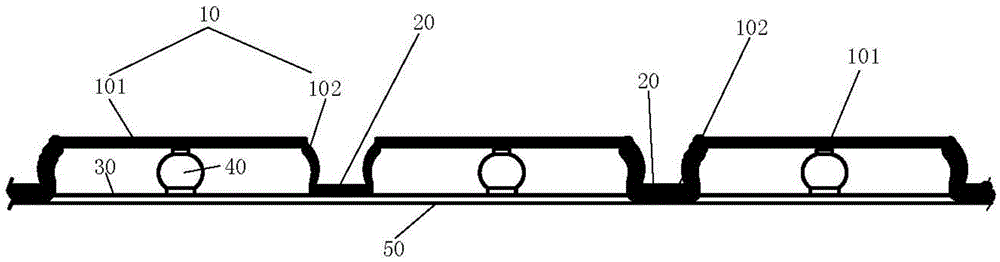

[0024] like Figure 1-6 As shown, the present invention discloses a keyboard with hollow keys and elastic silicone body. The keyboard only consists of an integrated key 10, a key grid bracket 20, a printed circuit film 30 located under the integrated key 10, and a printed circuit film fixed on the printed circuit board. The elastic silicone body 40 on the thin 30 switch 31 and the keyboard chassis 50 supported under the printed circuit film 30;

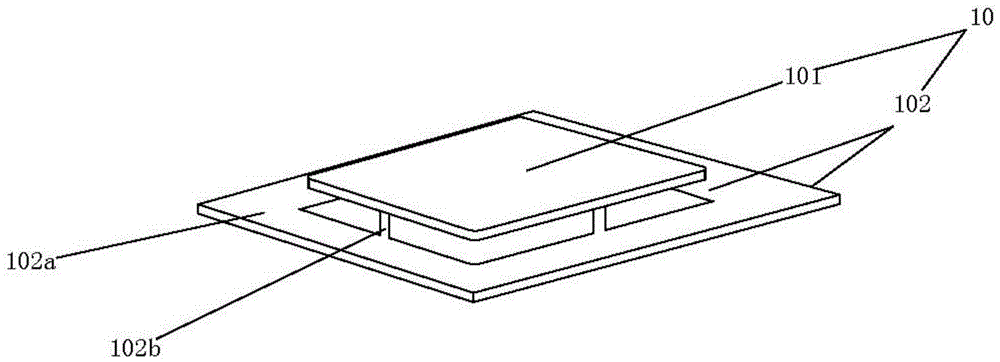

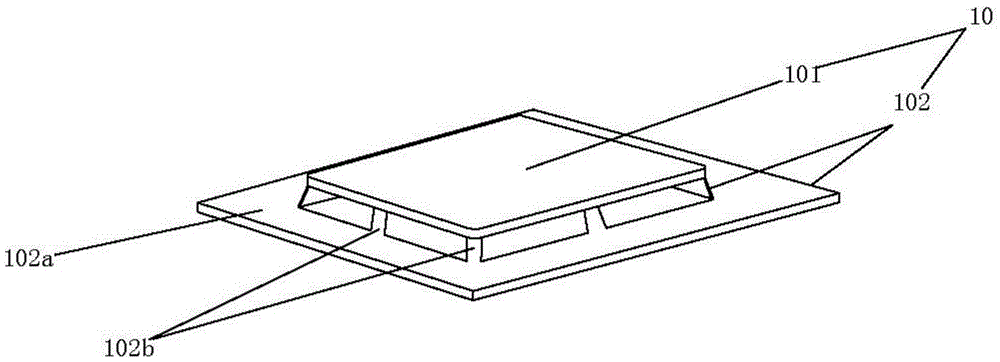

[0025] The one-piece key 10 is composed of several hard rubber key surfaces 101 and several elastic soft rubber connectors 102 through secondary injection molding of soft and hard rubber to form several one-piece buttons with cap-shaped structures, and the soft rubber connectors 102 is formed by a soft rubber plane layer 102a and a soft rubber side layer through a soft rubber injection molding. The software side layer is a hollow structure. The soft rubber supports the hollow part between the connecting parts 102b;

[0026] The key ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com