PWM-wave-controlled electromagnetic relay driving circuit and implementation method

An electromagnetic relay and drive circuit technology, applied in relays, circuits, electrical components, etc., can solve the problems of long arcing time, contact bounce, electromagnetic relay failure, etc., and achieve safe and stable operation, cost saving, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

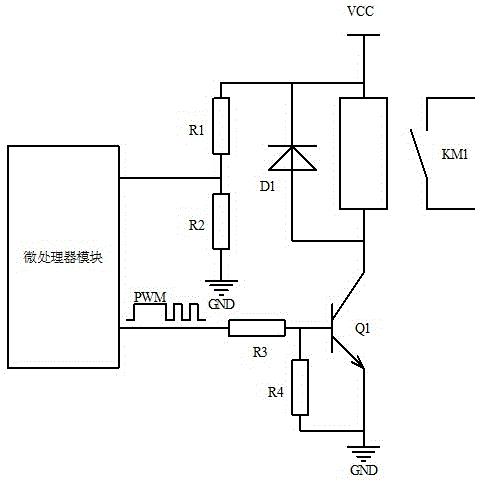

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

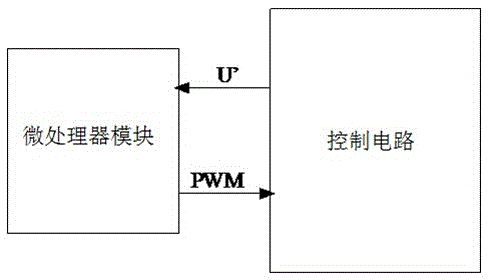

[0038] figure 2 It is a structural block diagram of an electromagnetic relay drive circuit controlled by PWM waves disclosed by the present invention, including a microprocessor module and a control circuit.

[0039] Wherein: the microprocessor module is a circuit module including a microprocessor (MCU) of a central processing unit (CPU), a digital signal processor (DSP), a complex programmable logic device (CPLD) or a programmable controller (PLC);

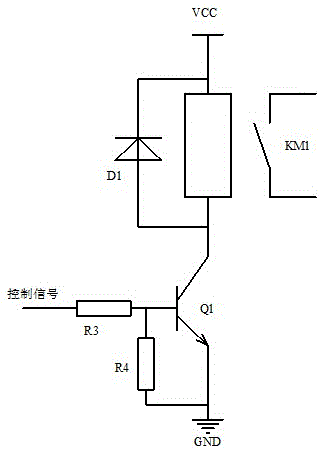

[0040] combine image 3 , The control circuit includes a drive circuit power supply VCC, a freewheeling diode D1, an electromagnetic relay KM1, a triode Q1, a resistor R1, a resistor R2, a resistor R3, and a resistor R4. The relationship between each composition is: one end of the resistance R1 is connected to the power supply VCC of the electromagnetic relay drive circuit, the other end is connected to the resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com