Self-generating device for freight train safety monitoring system

A technology for safety monitoring and freight trains, applied in electromechanical devices, circuit devices, battery circuit devices, etc., can solve the problems of increasing the volume of the bogie, adverse driving safety, affecting the maintenance work of the axle of the bogie, etc., and is suitable for promotion and maintenance. Simple, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

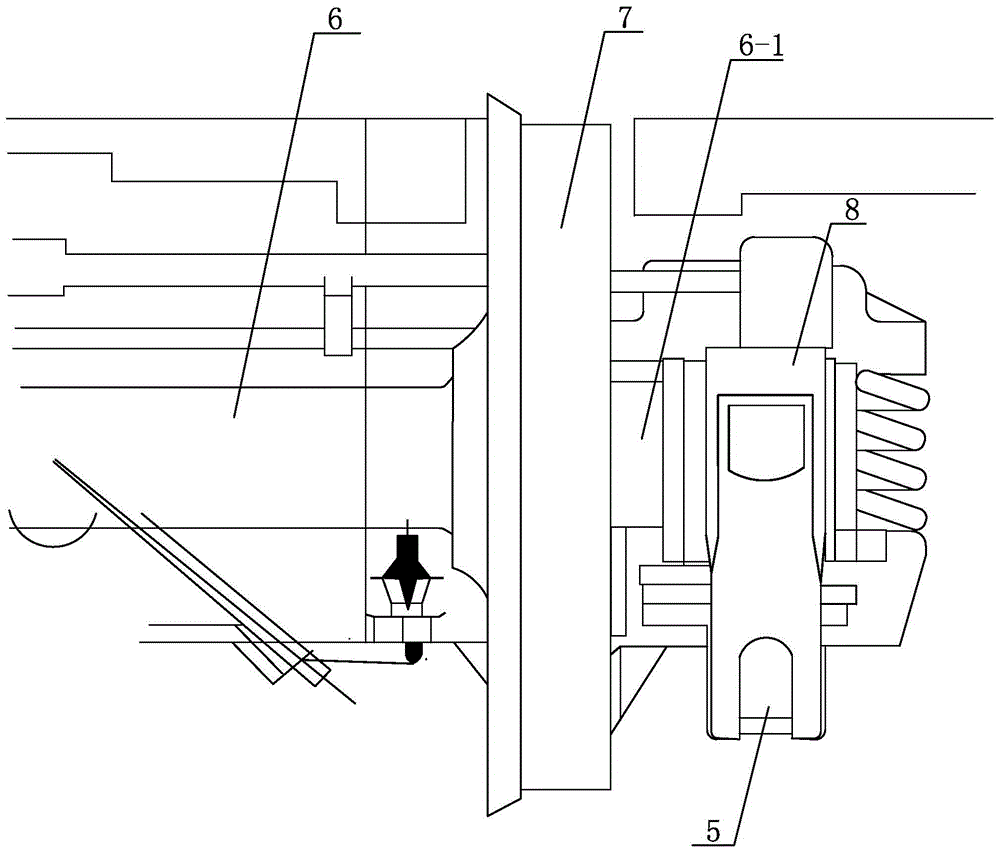

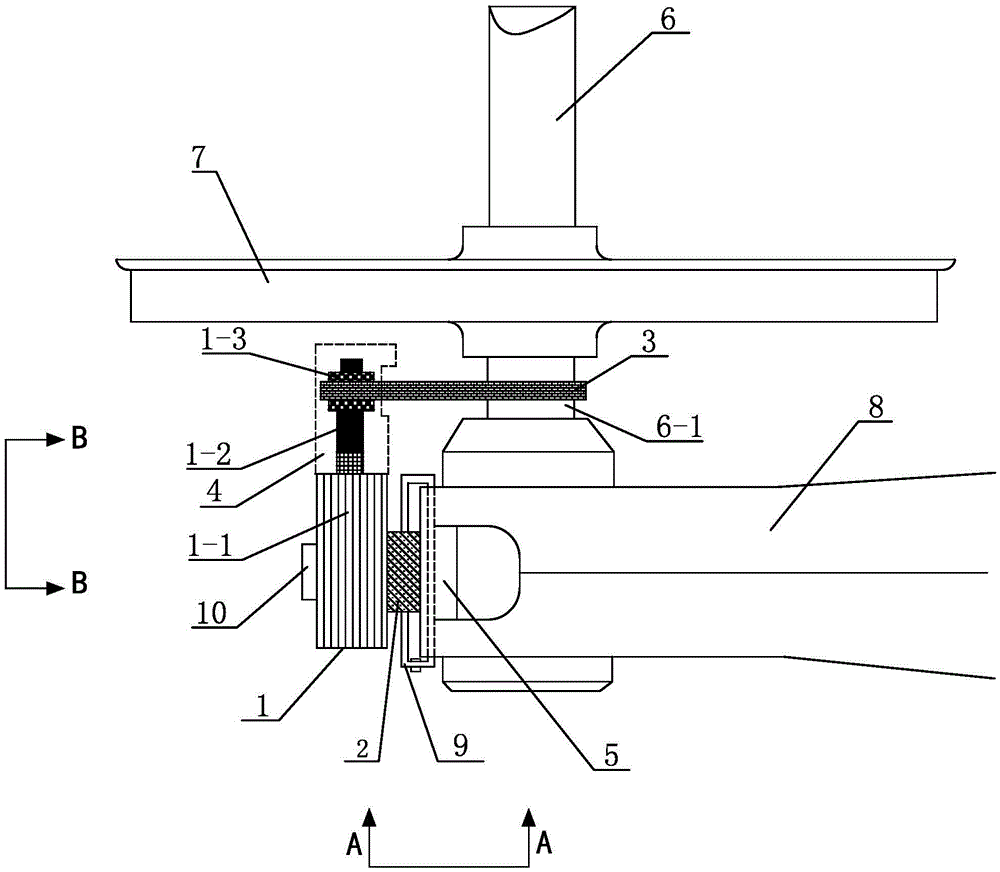

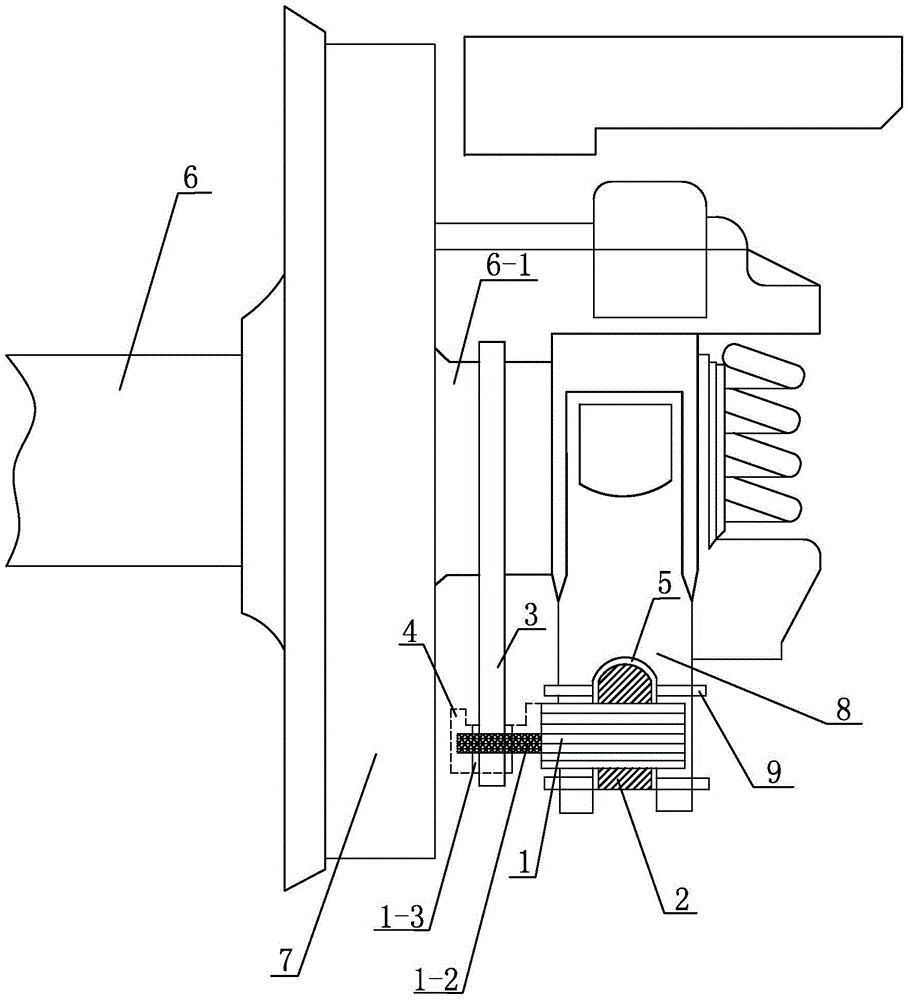

[0023] figure 1 It is a structural diagram of the self-generating device of the present invention that has not been installed on the bogie wheel axle. It includes an axle 6 and a wheel 7 installed on the axle. There is a bogie side frame 8 on the outside of the axle. 7 Between the outer rims is the groove 6-1 (a part of the axle) for the dust-proof plate seat on the axle. The slots are originally there, left when casting the bogie sideframes.

[0024] Such as figure 2 , 3 , 4, the feature of the present invention is to embed a wedge 2 whose size matches the internal shape of the groove in a side frame groove 5 at the lowest end, and connect the wedge 2 to the bogie side frame with hoop I9. 8 is firmly fixed. On the outside of the wedge block 2, a rotating shaft generator 1 is fixed with a hoop II 10. The rotating shaft 1-2 of the generator stretches toward the wheel direction and the generator drive wheel 1-3 is installed at the end of the shaft. The generator drive wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com