Filling device for motor vehicle operating fluid container

A technology of working fluid and filling device, which is applied in the direction of power plant, container, and arrangement combined with internal combustion engine fuel supply, etc. It can solve the problem of large filling connectors, reduce the complexity of assembly, reduce the number, and return splash reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

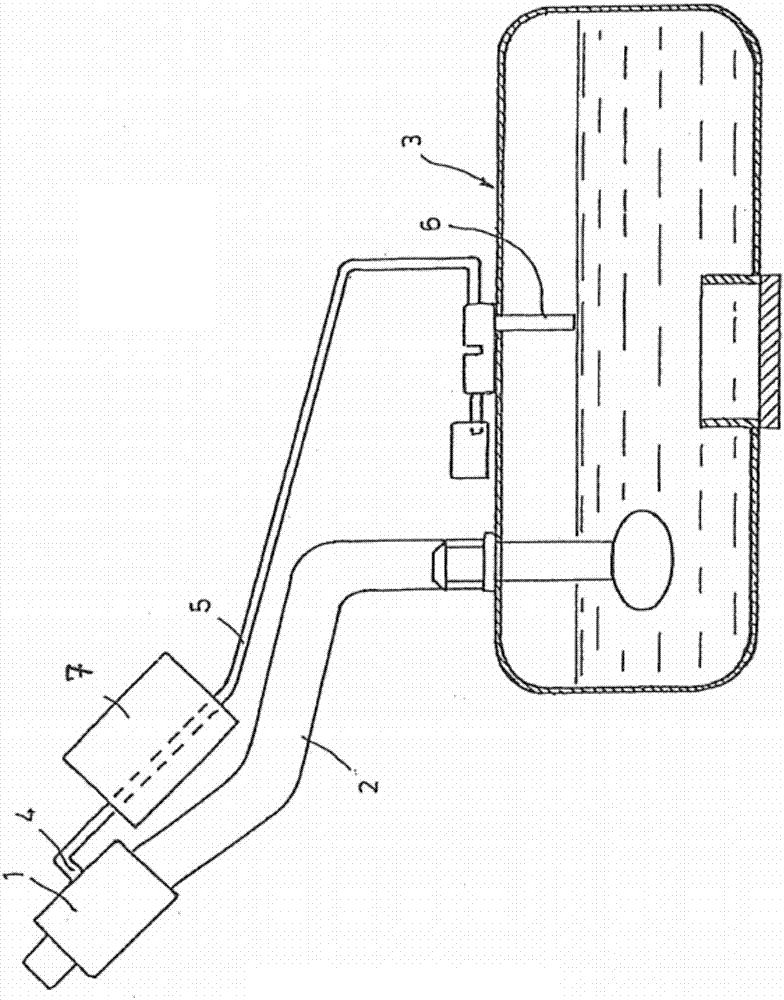

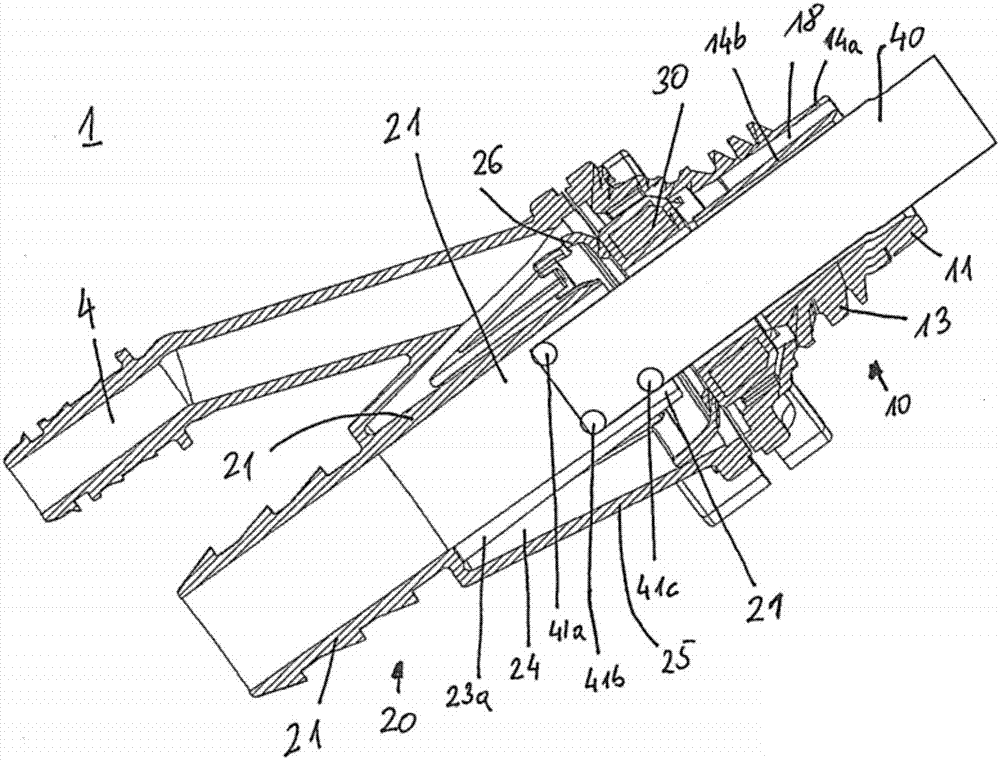

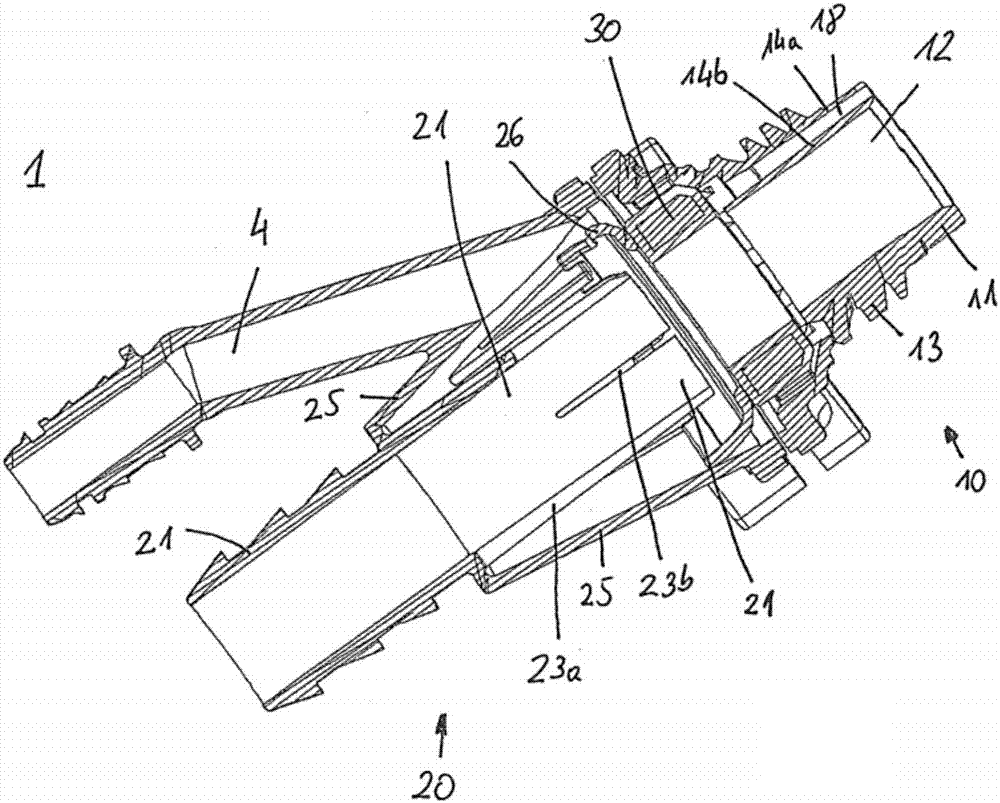

[0034] as in figure 1 As can be seen in the figure, the filling device 1 or the filling connection 1 according to the invention is arranged on the filling pipe 2 of the working fluid container 3 . In the described exemplary embodiment, the working fluid container 3 is designed as a urea container 3 for a urea solution as reducing agent for catalytic denitrification of exhaust gases in motor vehicles.

[0035]The working fluid container 3 can be configured as a one-piece extrusion-blow-molded plastic container. The filling tube 2 and the filling connection 1 can also consist of a thermoplastic material. The filling connector 1 and the remaining components described can also be produced by injection molding. In the exemplary embodiment, the entire arrangement including the filling connection 1 , the filling tube 2 and the working fluid container 3 is constructed in multiple parts. As described below, the filling connection 1 is designed as a filling head with a connection 4 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com