Electric pump

An electric pump, electric motor technology, applied in the direction of electric motor control, pump, pump device, etc., to achieve the effect of increasing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

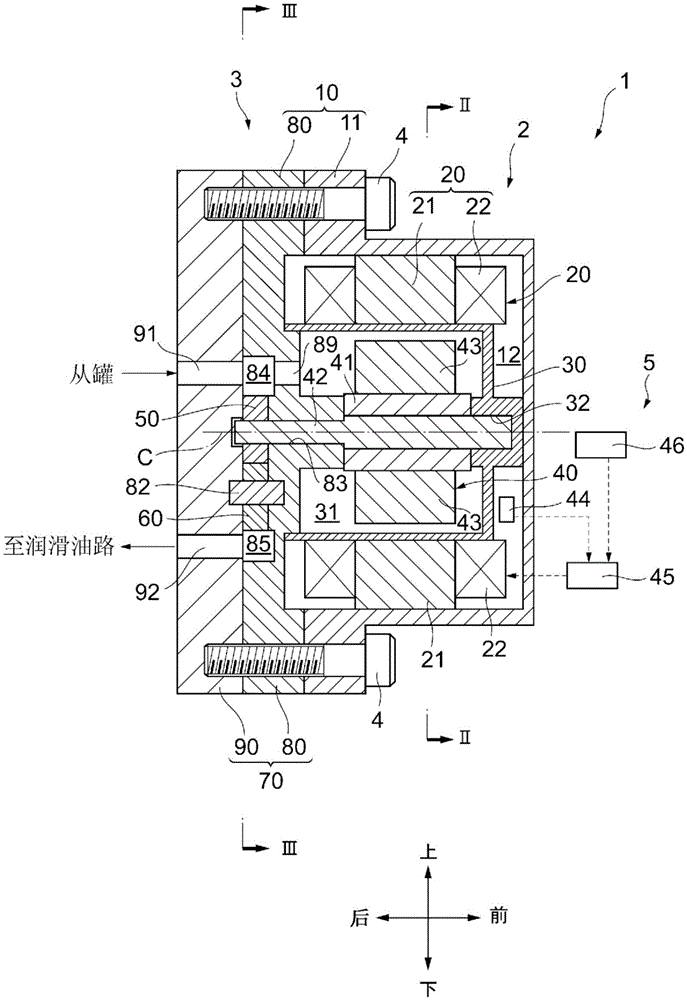

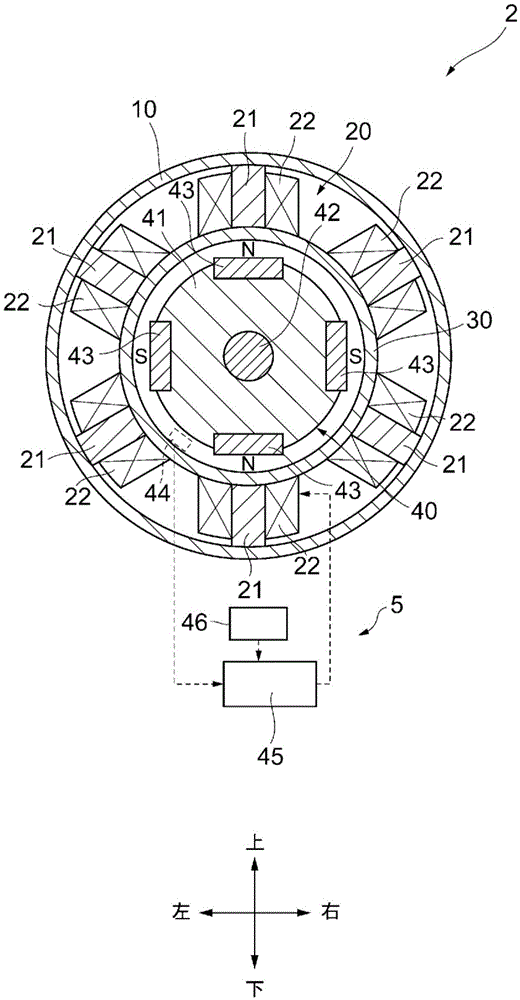

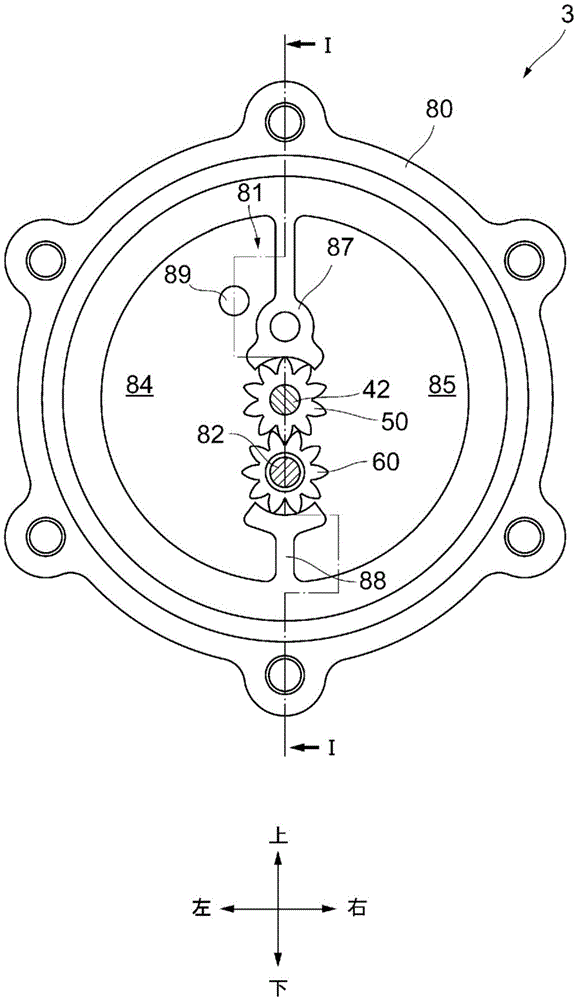

[0023] Hereinafter, embodiments of the present invention will be described with reference to the drawings. exist figure 1 2 shows a cross-sectional view of an electric oil pump 1 as an example to which the present invention is applied. First, refer to this figure 1 The overall structure of the electric oil pump 1 will be described. In addition, in the embodiments described below, for convenience of description, front and rear, left and right (indicated by arrows attached to each figure) are used to define figure 1 The arrow is not shown in , but it is a direction perpendicular to the paper surface) and up and down will be described. In addition, in the present embodiment, an electric oil pump 1 is exemplified that sucks lubricating oil stored in a tank provided in a vehicle (for example, an engine oil pan) and discharges it to lubricating oil passages connected to various parts of the engine.

[0024] The electric oil pump 1 is configured to include: an AC-type electric ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap