Liquid injected screw compressor, controller for the transition from an unloaded state to a loaded state of such a screw compressor and method applied therewith

A technology of screw compressors and compressors, which is applied to components of pumping devices for elastic fluids, rotary piston type/swing piston type pump components, machines/engines, etc., and can solve the problem of complex and impractical solutions. , short response time and other problems, to achieve the effect of eliminating risk of failure, simple control, and realization of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

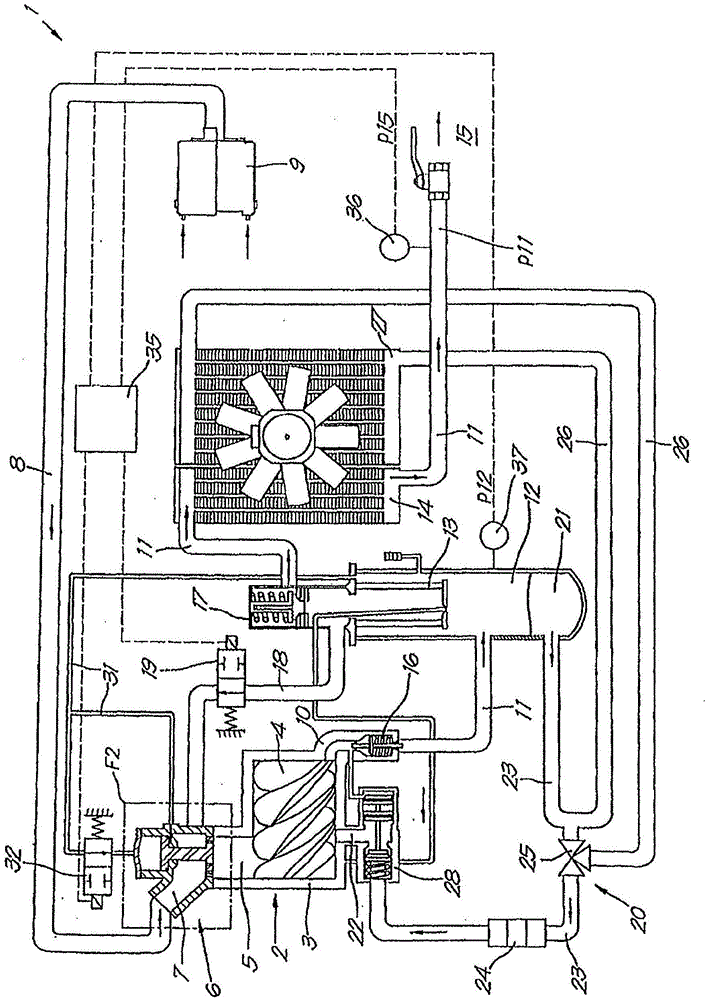

[0036] figure 1 The device shown in is a liquid-injected screw compressor 1 according to the invention comprising a known screw compressor element 2 having a housing 3 in which two meshing screw rotors 4 are driven by a motor or the like (not shown).

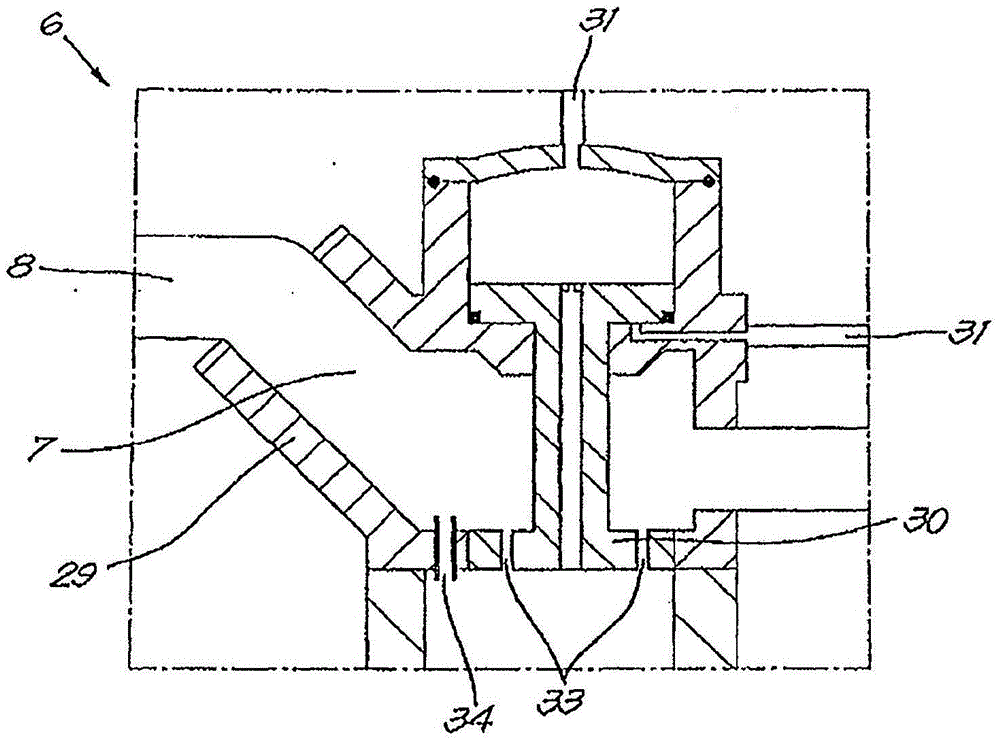

[0037] The compressor element 2 is provided with an inlet 5 which can be closed by a controllable inlet valve 6, the inlet 7 of which is connected via a suction pipe 8 to a suction filter 9 for sucking gas from the outside (in this case In this case, air is drawn in from the outside).

[0038] The compressor element 2 is also provided with an outlet 10 and a pressure pipe 11 connected to the outlet, which is connected to a downstream consumer network 15 for passage through a pressure vessel 12 with a liquid separator 13 and through cooling Device 14 supplies various air tools or the like (not shown herein).

[0039] A non-return valve 16 is provided on the outlet 10 of the compressor element 2 and a minimum pressure valve 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com