Device for synchronously carrying out topping and bud picking on tobaccos

A technology of tobacco and liquid inlet, applied in trimming shears equipment, botanical equipment and methods, gardening and other directions, can solve the problems of increasing the production cost of tobacco farmers, discounting production technology, affecting the quality of tobacco leaves, etc., and achieving easy popularization, use and operation. Convenience and the effect of reducing the chance of infection of tobacco plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

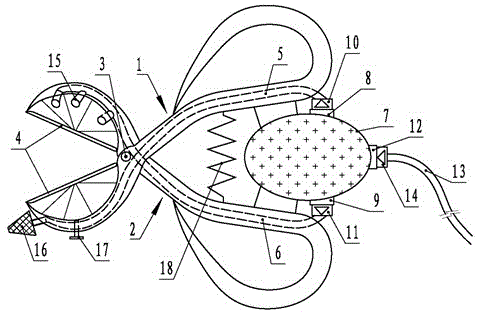

[0022] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

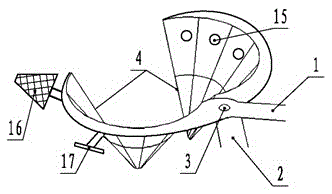

[0023] like figure 1 As shown, a device for synchronously performing tobacco topping and bud wiping includes a back strap and a scissors device. The second body 2 is composed of the first body 1 and the second body 2 connected by the rotating shaft 3. The front end of the first body 1 and the second body 2 is a shearing part, and the rear end is a handle. cutting edge 4.

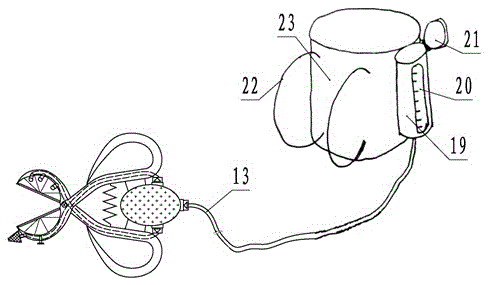

[0024] An elastic liquid storage bag 7 is arranged between the handles of the first body 1 and the second body 2, and a first liquid outlet 8, a second liquid outlet 9 and a liquid inlet 12 are arranged on the liquid storage bag 7 , the liquid inlet 12 is connected with a hose 13, and the hose 13 is connected to a cylinder 19 for containing the sprout suppressant, and the cylinder 19 is vertically installed on the drum body 23.

[0025] A flexible coating head 16 is provided at the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com