Starch sugar finished product barrel automatic thawing pool

A starch sugar and finished product technology, which is applied in sugar production, sugar production, glucose production, etc., can solve the problems of inconvenient transportation and use of finished starch sugar in barrels, and achieve the effect of avoiding freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

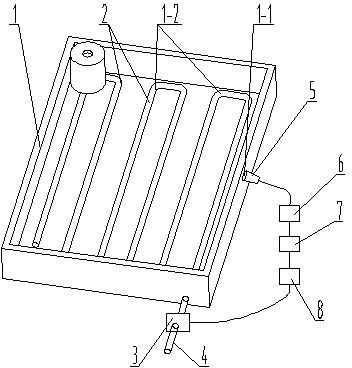

[0008] Such as figure 1 As shown, the present invention includes a defrosting tank 1, a set of steam pipes 2, a solenoid valve 3, a steam pipe 4, a temperature sensor 5, an analog input module 6, a PLC 7 and an analog output module 8. The defrosting tank 1 is provided with a temperature detection hole 1-1 and a set of pipeline installation grooves 1-2, and a set of pipeline installation grooves 1-2 are located at the bottom of defrosting tank 1, and a set of steam pipes 2 are installed in a set of pipeline installation grooves 1-2 of defrosting tank 1. , The outlet of the solenoid valve 3 communicates with the inlet of a group of steam pipes 2, the outlet of the steam pipe 4 communicates with the inlet of the solenoid valve 3, the temperature sensor 5 is installed in the temperature detection hole 1-1 of the defrosting tank 1, and the temperature sensor 5 The sensor head is located inside the defrosting pool 1, the analog input module 6 is connected to the signal output termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com