Liquid Supported Carbon Dioxide Separation Membrane

A carbon dioxide and separation membrane technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problem of low selectivity, and achieve the effects of low preparation cost, high solubility and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

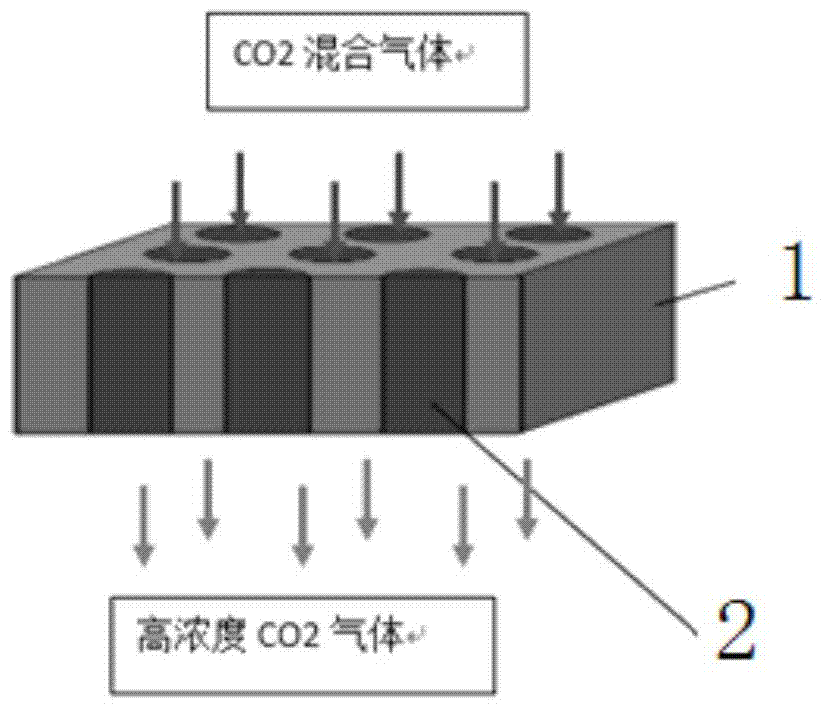

[0033] The liquid-supported carbon dioxide separation membrane of this embodiment includes organic matter dissolved in dimethylformamide and heat-treated to become the main component. The organic matter is polyethylene polyamine and polyethersulfone resin. The principle model of the liquid-supported carbon dioxide separation membrane is shown in Fig. figure 1 As shown, the separation membrane includes a polymer membrane substrate with a porous structure and a carbon dioxide polymer adsorbent adsorbed in the porous structure; the polymer membrane substrate 1 is a polyethersulfone resin to provide the separation membrane as a whole Mechanical strength, the carbon dioxide polymer adsorbent 2 is polyethylene polyamine, which has a relatively high boiling point and can well complete the CO 2 adsorption and desorption.

[0034] The preparation method of the liquid-supported carbon dioxide separation membrane of this embodiment is specifically as follows:

[0035] Step 1: Take 2.5g...

Embodiment 2

[0041] The liquid-supported carbon dioxide separation membrane of this embodiment includes organic matter dissolved in dimethylformamide and heat-treated to become the main component. The organic matter is polyethylene polyamine and polyethersulfone resin,

[0042] Its preparation method is as follows:

[0043] Step 1: Take 2g of polyethylene polyamine and 3g of polyethersulfone resin as the main solute of the separation membrane.

[0044] Step 2: Add 21 g of dimethylformamide solvent to the solute, and heat and stir at 80° C. to dissolve to form a separation membrane precursor solution.

[0045] Step 3: Pour the solution evenly on the substrate, and adjust the scraper to 240 μm to scrape it to the size of A4 paper.

[0046] Step 4: Put the substrate into a constant temperature drying oven at 80° C. for 3 hours of heat treatment.

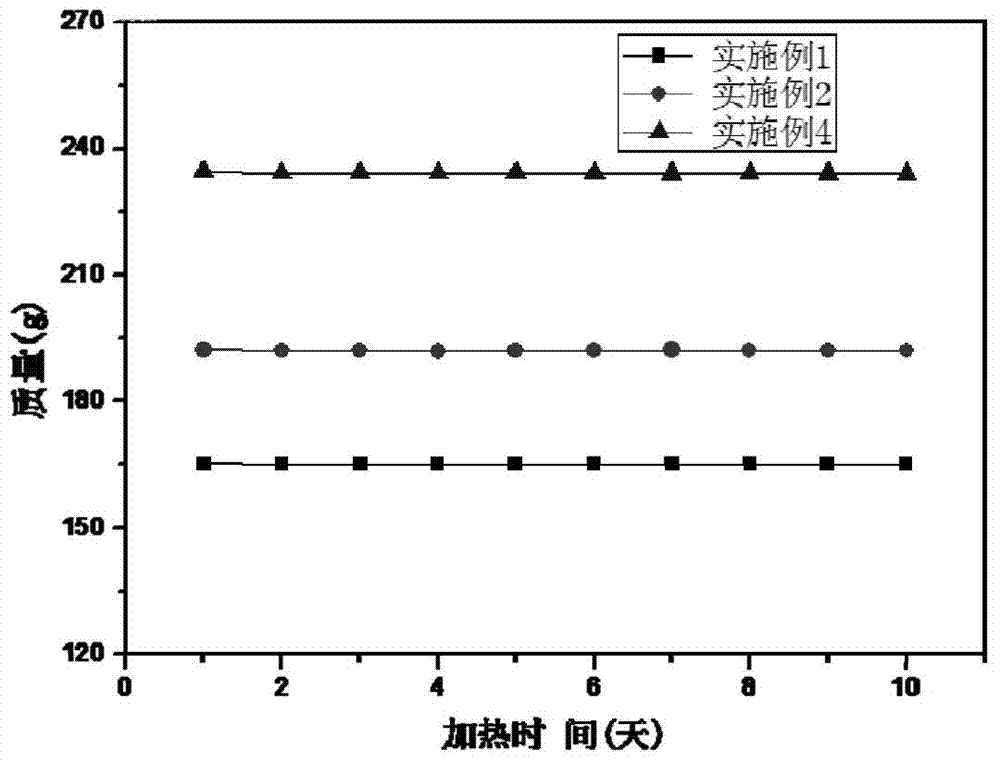

[0047] Step 5: Take out the substrate, and after it cools down, remove the film from the substrate, that is, a film with a thickness of 60 μm and a...

Embodiment 3

[0049] The liquid-supported carbon dioxide separation membrane of this embodiment includes organic matter dissolved in dimethylformamide and heat-treated to become the main component. The organic matter is polyethylene polyamine and polyethersulfone resin,

[0050] Its preparation method is as follows:

[0051] Step 1: Take 2.5g polyethylene polyamine and 5g polyethersulfone resin as the main solute of the separation membrane.

[0052] Step 2: Add 22.5 g of dimethylformamide solvent to the solute, and heat and stir at 70° C. to dissolve to form a separation membrane precursor solution.

[0053] Step 3: Pour the solution evenly on the substrate, and adjust the scraper to 160 μm to scrape it to the size of A4 paper.

[0054] Step 4: Put the substrate into a 90° C. constant-temperature drying oven for 3 hours of heat treatment.

[0055] Step 5: Take out the substrate, and after it cools down, remove the film from the substrate, that is, a film with a thickness of 40 μm and a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com