Double-row cylindrical article pneumatic removing device

A rejecting device, cylindrical technology, applied in the field of double exhaust dynamic rejecting device for cylindrical items, to achieve the effect of easy maintenance, simple structure and accurate removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below with reference to the drawings.

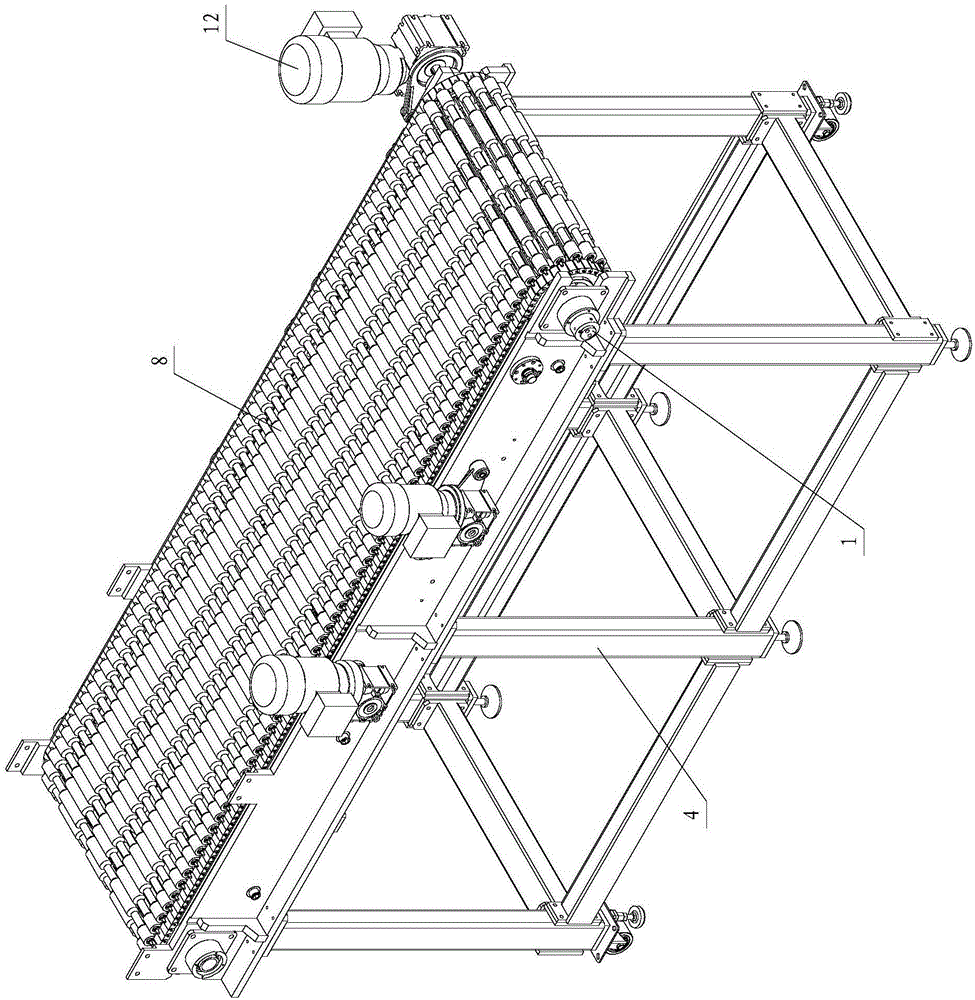

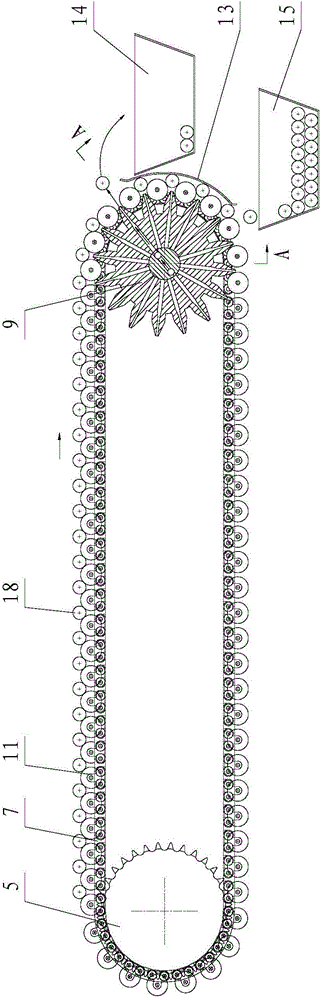

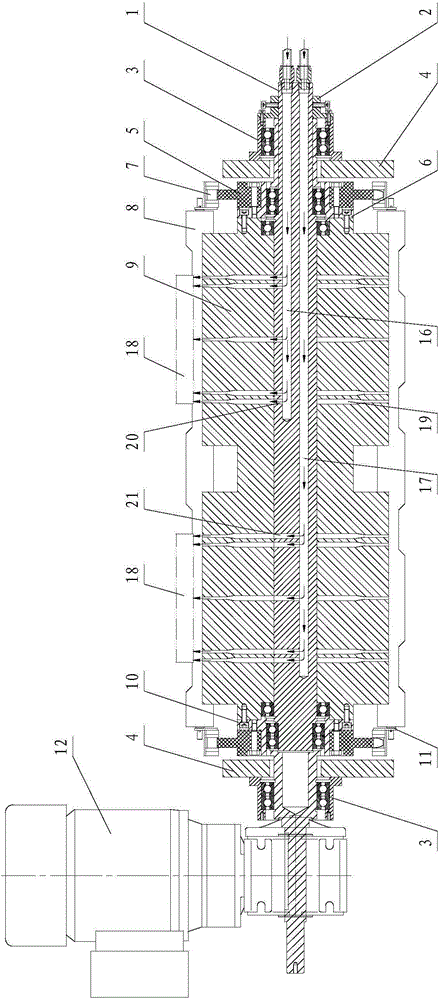

[0021] Such as Figure 1~5 As shown, the present invention includes blowing mandrel 1, positioning disc 2, bearing seat 3, frame body 4, sprocket 5, driven flange 6, chain 7, chain roller 8, air guide wheel 9, and driving flange 10. , The connecting plate 11, the geared motor 12, the guard plate 13, the recovery box 14 and the finished product box 15, in which a rotatable sprocket 5 is provided on the left and right sides of the two ends of the frame 4, and the two sprocket 5 on the same side Are connected by a chain 7; a plurality of chain rollers 8 are arranged between the chains 7 on both sides, and each chain roller 8 is connected to a chain link through a connecting plate 11, so that the chain wheels 5 at both ends can be driven by the chain 7 The roller 8 moves. The cylindrical articles 18 move with the chain roller 8 from one end of the frame 4 to the other end. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com