Heating equipment

A technology of heating equipment and a heating furnace, which is applied in the field of machinery, can solve problems such as poor heat uniformity, difficult to accurately control temperature, and reduce target quality, so as to reduce the difference in heating deformation, improve heating uniformity, and improve heating quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] As mentioned in the background technology, during the use of the existing welding platform, the heat uniformity of each part of the hot oven plate is poor, which makes it difficult to accurately control the temperature of the hot oven plate; in addition, after a period of use, the hot oven plate There are also obvious deformation problems, and the above problems will affect the quality of target brazing. Analyze its reasons:

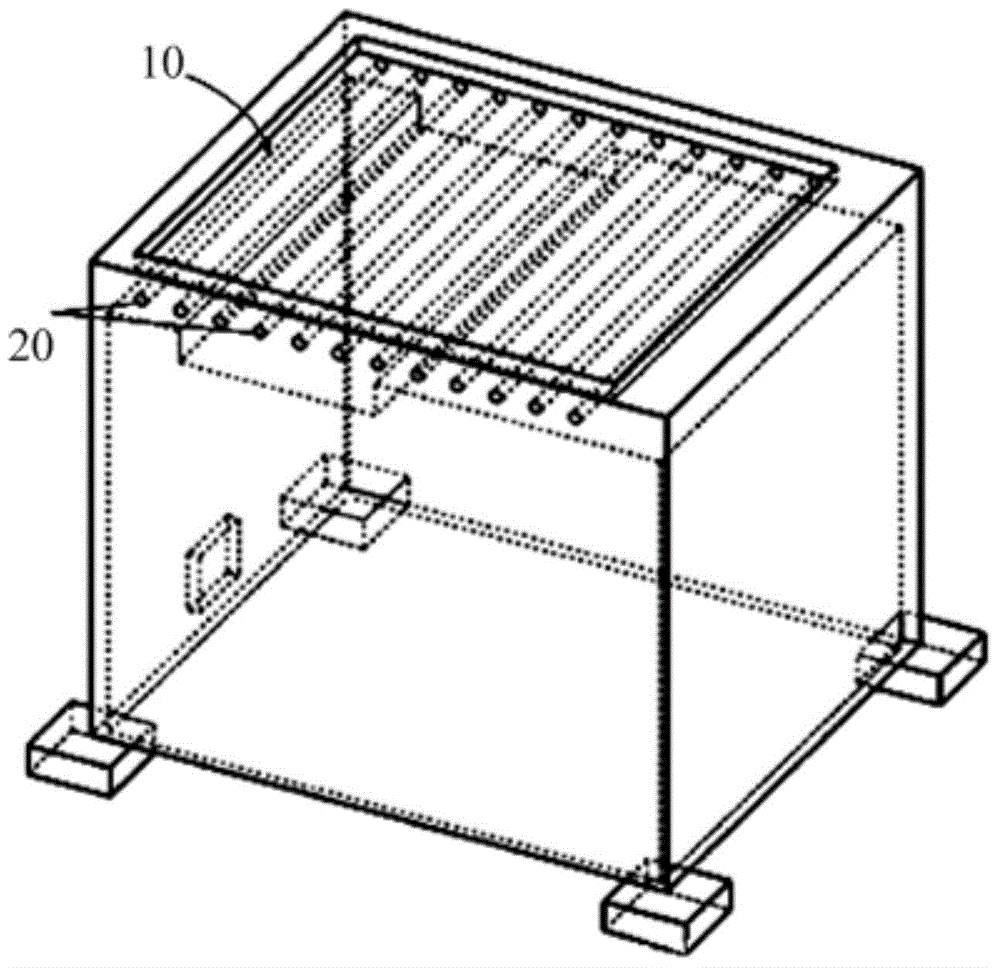

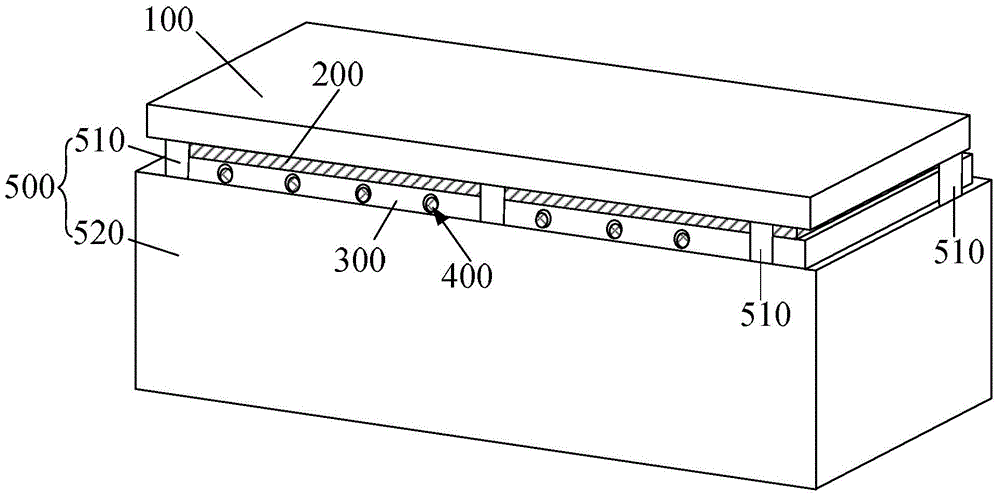

[0041] combined reference figure 1 , the heating tube 20 of the existing welding platform is directly in contact with the heating furnace plate 10 to provide heat to the heating furnace plate 10. During use, the difference in the heating of each part of the heating furnace plate 10 will be caused by the difference in the distribution of the heating tubes 20. Thereby causing the problem that the temperature of the hot oven plate 10 is difficult to accurately control; and, after using for a period of time, the hot oven plate 10 will be heated and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com