Power supply system used for ultrasonic welder

A technology of ultrasonic welding and power supply system, applied in the field of ultrasonic welding, can solve the problems of output amplitude stability and continuous adjustability being difficult to meet actual requirements, poor frequency automatic tracking performance, etc., to achieve convenient function expansion, stable output amplitude, fast and accurate tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and embodiments.

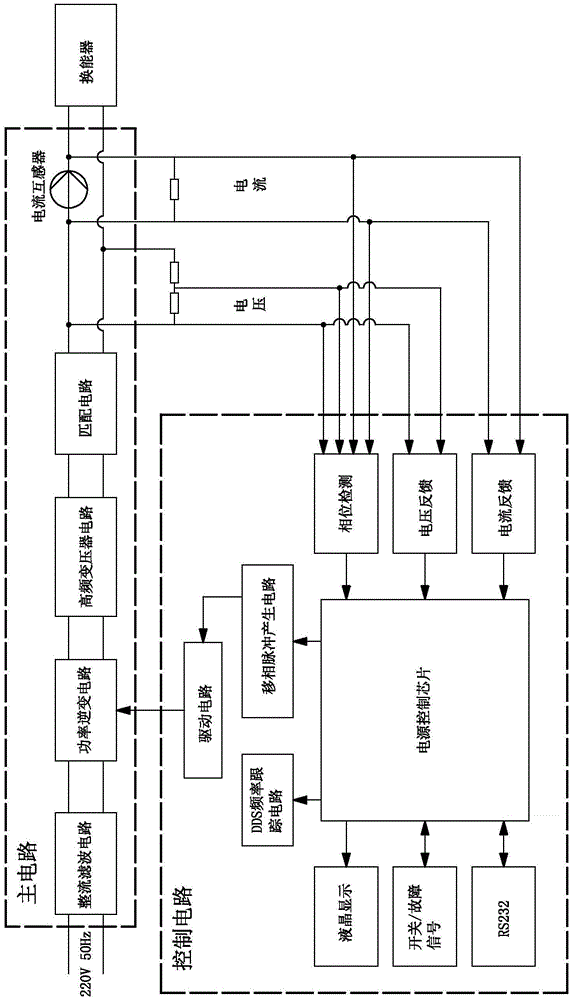

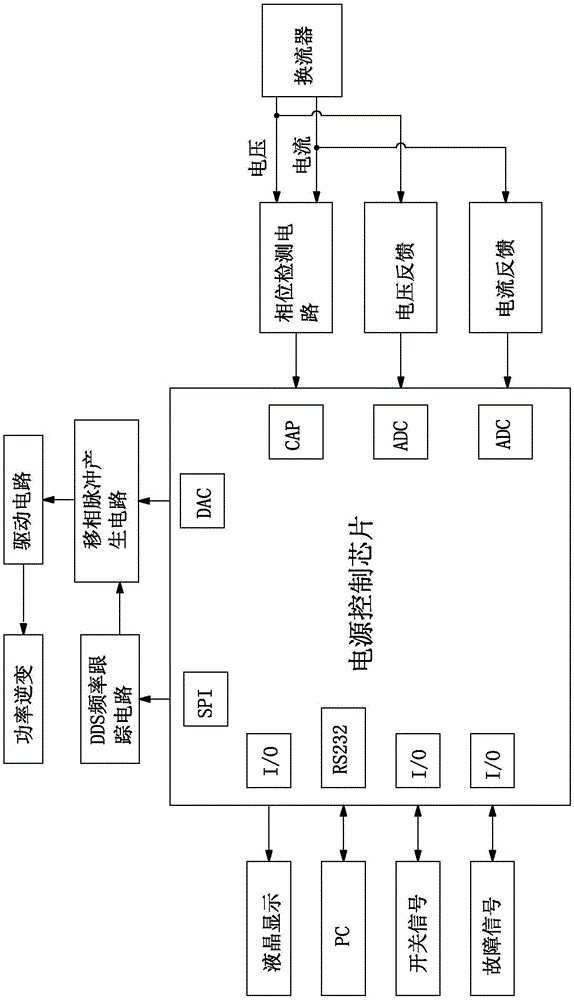

[0020] see figure 1 , This power supply system for ultrasonic welding machine includes a main circuit and a control circuit; it is characterized in that: the main circuit includes a rectifier filter circuit, a power inverter circuit and a high-frequency transformer connected in sequence; the control circuit includes a phase detection circuit Circuit, voltage feedback circuit, current feedback circuit, power control chip, DDS frequency tracking circuit, phase-shifting pulse generating circuit and driving circuit; the phase detection circuit, voltage feedback circuit, current feedback circuit, DDS frequency tracking circuit and phase-shifting pulse The generating circuits are respectively connected with the power supply control chip, and the phase-shifting pulse generating circuit is connected with the power inverter circuit through the driving circuit.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com