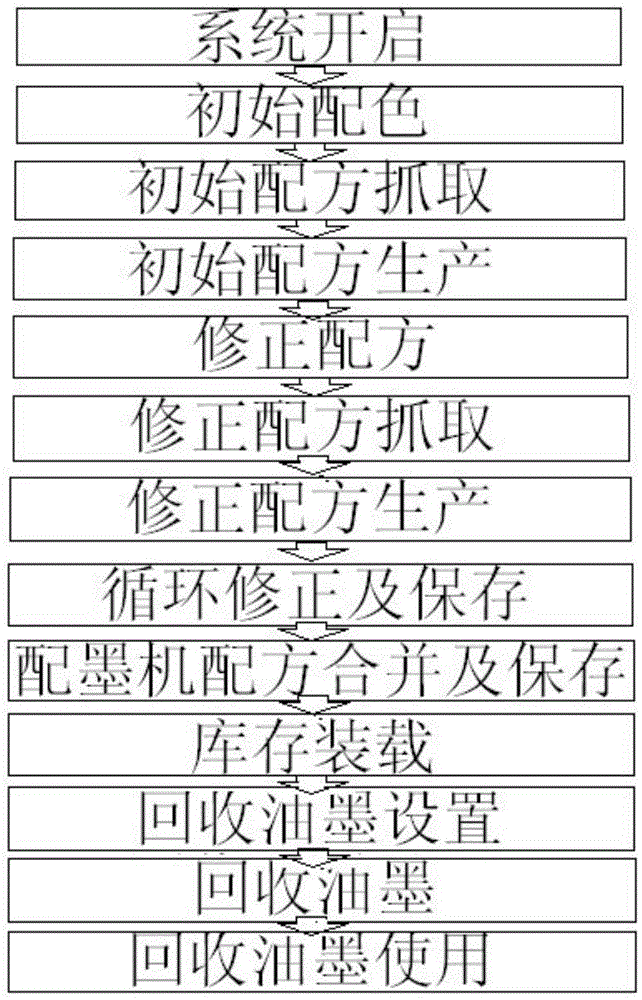

Intelligent water-based ink color blending working process

A water-based ink and workflow technology, which is used in printing, printing machines, general parts of printing machinery, etc., can solve the problems of lack of color matching, incomplete color matching, etc., to achieve consistent color, maintain consistent color, and eliminate color difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] An intelligent water-based ink color matching workflow, specifically:

[0034] 1) The system is turned on

[0035] Turn on the color matching ink distribution system. On the one hand, open the remote link by opening the color matching ink distribution system. The color matching software, color measuring instrument and ink distribution machine system are in working condition. By starting the color matching software, preset opacity and detect the roughness of the substrate to be printed , Connect the color measuring instrument; on the other hand, open the ink dispensing machine system by opening the color matching ink dispensing system, the ink dispensing machine system realizes automatic circulation, checks the remaining material in the ink dispensing machine barrel, and turns on the compressed air function;

[0036] 2) Initial color matching

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com