Flush box type multi-mode stabilization device

An anti-rolling device and multi-modal technology, applied in the direction of reducing ship motion through displacement, can solve the problems of frequent swinging rudder blades, increasing sailing resistance, and not too many actual ship applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

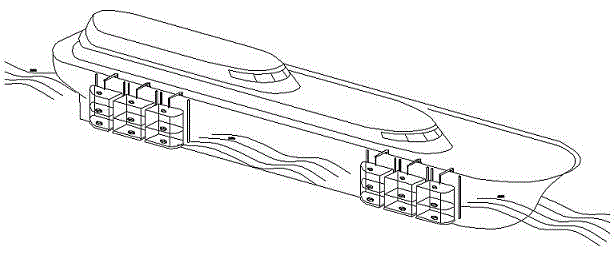

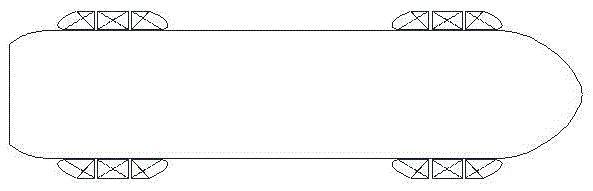

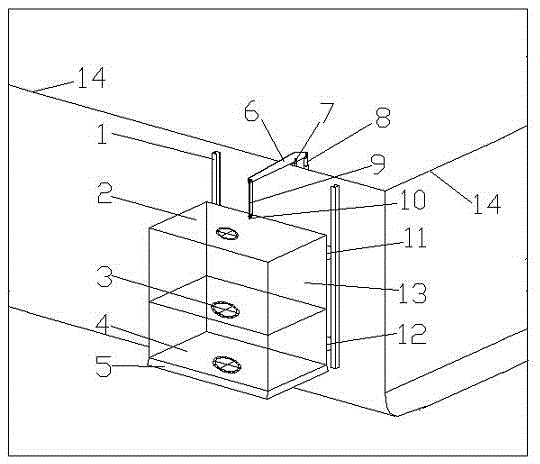

[0028] Such as Figure 1 to Figure 15As shown, the punching box type multi-mode anti-rolling device includes the punching box top plate 2, the middle partition plate 3, the punching box bottom plate 4, the rocker arm 6, the driving power device 8, the connecting rod 9, the connecting shaft 10, the upper roller 11, Lower roller 12 and box body 13, box top plate 2 and box bottom plate 4 are respectively installed on the upper and lower ends of box body 13, middle partition plate 3 is installed in box body 13, one end of connecting rod 9 is connected with rocking arm 6, and the other One end is connected to the box body 13 through the connecting shaft 10, the driving power device 8 is connected to the rocker arm 6, the upper roller 11 and the lower roller 12 are respectively installed on the back of the box body 13, and the anti-rolling device is installed on the outboard of the ship. It is connected with the hull through the rocker arm. The track 1 is installed on the hull 14. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com