Composite tunnel anchorage structure

A tunnel anchor and composite technology, which is used in the installation of bolts, mining equipment, and earth-moving drilling, etc., can solve the problems of conservative engineering measures, slope instability, and weak slopes that are not easy to carry the main cable, and achieve a clear mechanical principle. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

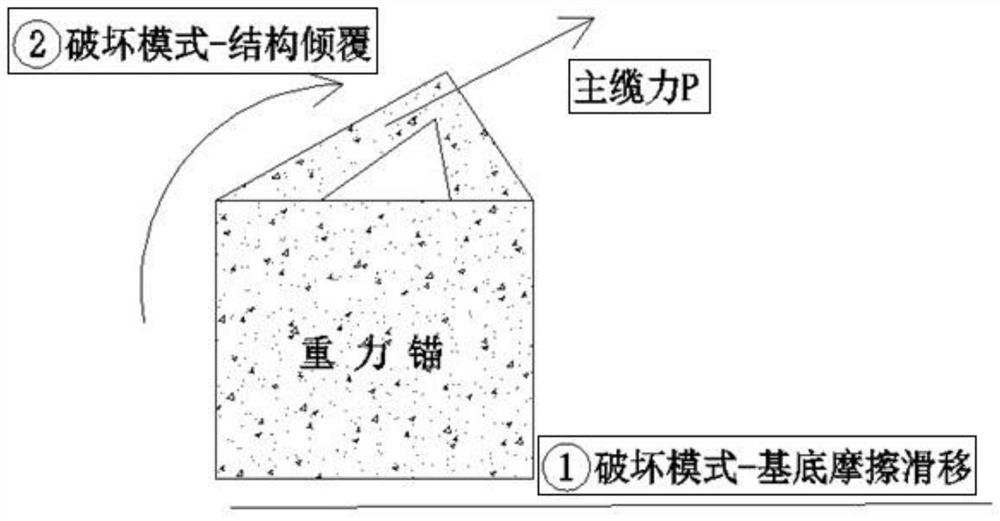

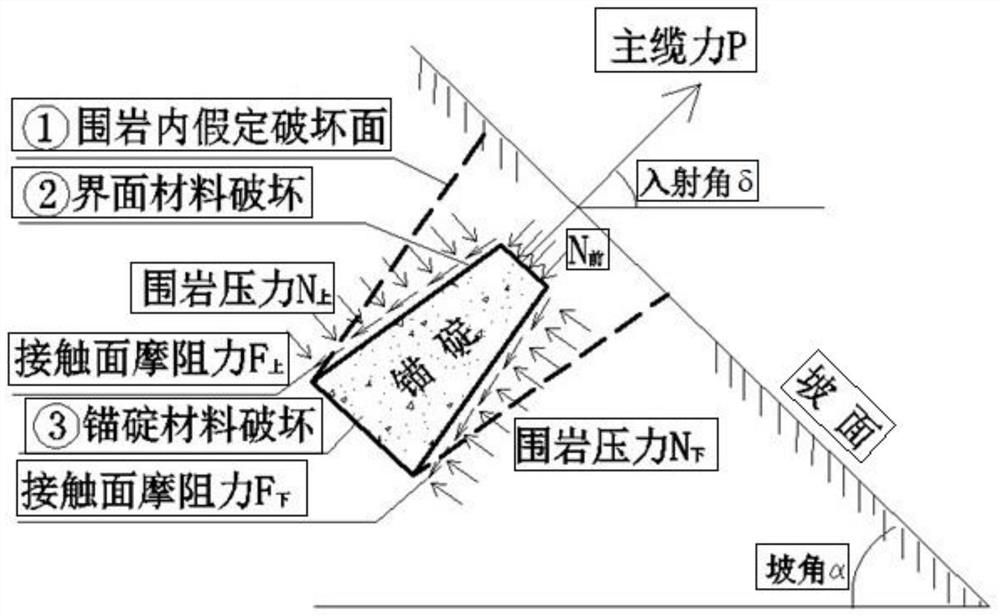

Problems solved by technology

Method used

Image

Examples

Embodiment 1

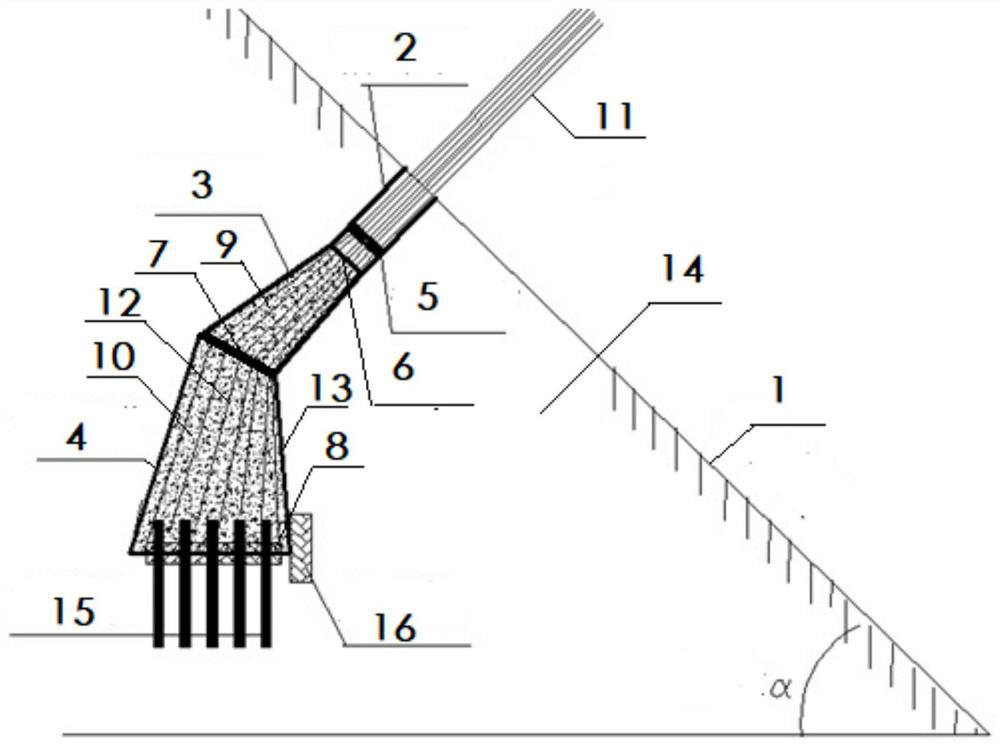

[0036] like image 3 , a composite tunnel anchorage structure, set in the rock layer 14 of the slope sliding surface 1, including the main cable access hole 2 parallel to the incident direction of the main cable 11, which is formed by successive excavation of the main cable access hole 2 Scattering room 3, wedge-shaped room 4, the average cross-sectional area of scatter room 3 is A=30m 2 And loose cable room 3 lower end to the length of upper end is a=10m, and the base area of wedge-shaped room 4 is B=50m 2 And the height is b=20m, after the excavation of the main cable access hole 2, loose cable room 3, and wedge-shaped room 4 is completed, the surrounding rock support layer 13 of the chamber is prepared by means of anchor spraying, etc., and the main cable access hole 2 is installed. There is a scatter saddle 5, and the end of the scatter chamber 3 close to the main cable access hole 2 is provided with a guide 6, the guide 6 includes a honeycomb structure composed of mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com