Mobile sewage continuous processor

A processor and mobile technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of inability to discharge liquid, low sewage treatment efficiency, etc., to avoid efficiency low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

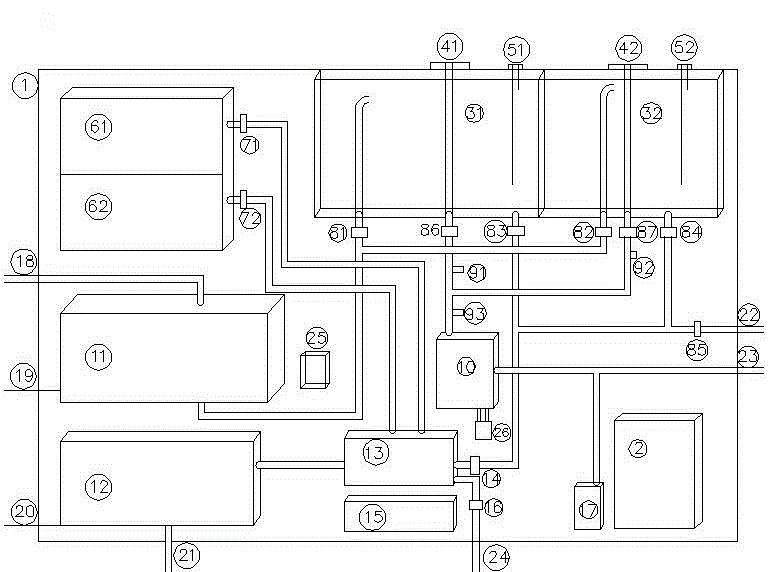

[0016] see figure 1 As shown in the figure, the mobile continuous sewage treatment machine of the present invention includes a casing 1 and equipment installed in the casing 1. The equipment includes a silent generator 2 for providing energy, a solid waste separation tank 11, first and second sewage Tanks 31, 32, water ring vacuum pump 10, mixing reaction tank 13, solid-liquid separator 12, first and second coagulant dissolution tanks 61, 62, ozone generator 17, electrical control box 15, and air compressor 25 .

[0017] The solid waste separation tank 11 is connected with a sewage inlet 18 and a solid waste outlet 19 . The solid waste separation tank 11 is connected to the first and second sewage tanks 61 and 62 respectively through pipes, and the pipes of the solid waste separation tank 11 connected to the first and second sewage tanks 31 and 32 are respectively installed with first and second sewage tanks 61 and 32 . 1. The second pneumatic valve 81, 82.

[0018] The top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com