Vacuum arc remelting furnace

A vacuum arc and remelting furnace technology, applied in the field of vacuum melting furnaces, can solve problems such as artificial control of crystals, inability to guarantee the accuracy and quality of crystal melting, uncontrollable magnetic field stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

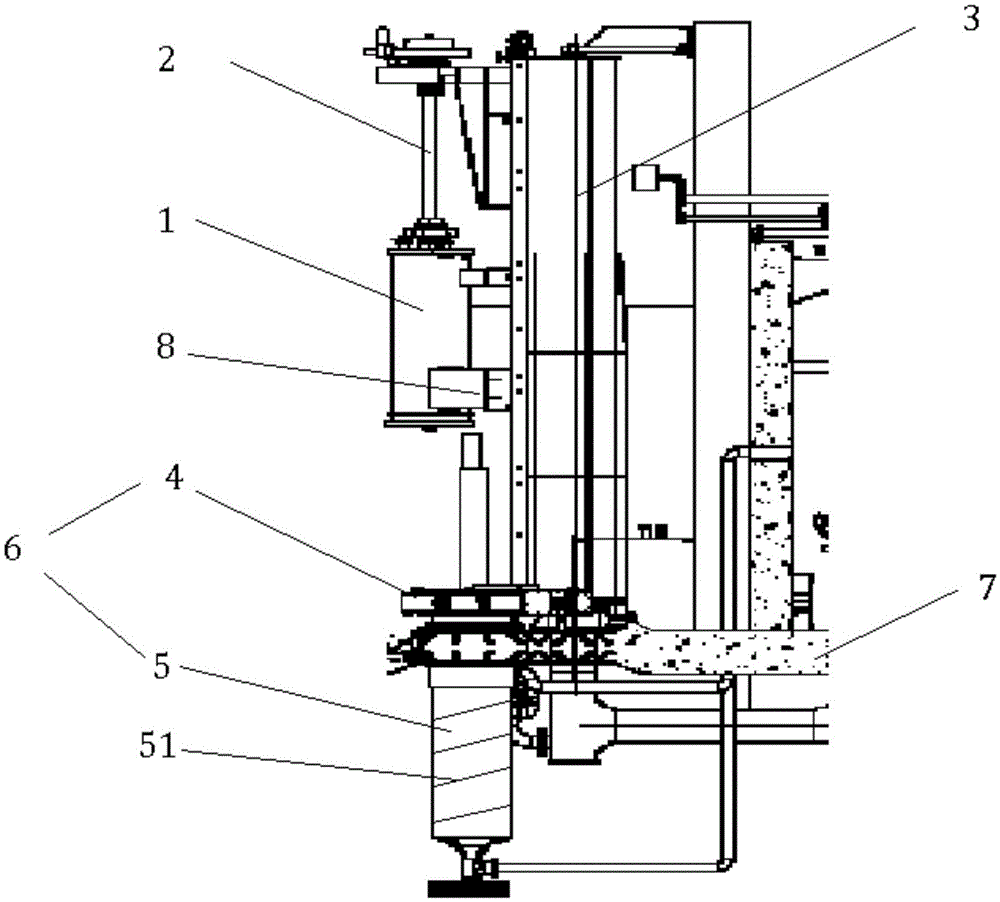

[0020] see figure 1 , a vacuum arc remelting furnace of the present invention includes a movable furnace head 1 and a static melting station 6 .

[0021] The movable burner head 1 is connected with the driving support 3 through a support mechanism 8 .

[0022] The conductive material rod 2 runs through the center of the movable burner 1 from top to bottom, and is connected with the movable burner 1 . The conductive material rod 2 is connected with the driving bracket 3 at the same time.

[0023] The static smelting station 6 includes a copper crystallizer 4 and a stainless steel water cooling jacket 5 .

[0024] The copper crystallizer 4 is movably placed in the stainless steel water cooling jacket 5, and the stainless steel water cooling jacket 5 is fixed under the movable bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com