Lightning stroke resistant metal unit capable of changing lightning attachment point and preparation method thereof

A metal unit, anti-lightning technology, applied in metal processing, aircraft electrostatic discharger, aircraft lighting protector, etc., can solve the problem of not being able to actively change the lightning entry point and conduction direction, etc., to achieve good practical value and the ability to conduct lightning current Strong, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a lightning-resistant metal unit capable of changing the lightning attachment point, comprising the following steps:

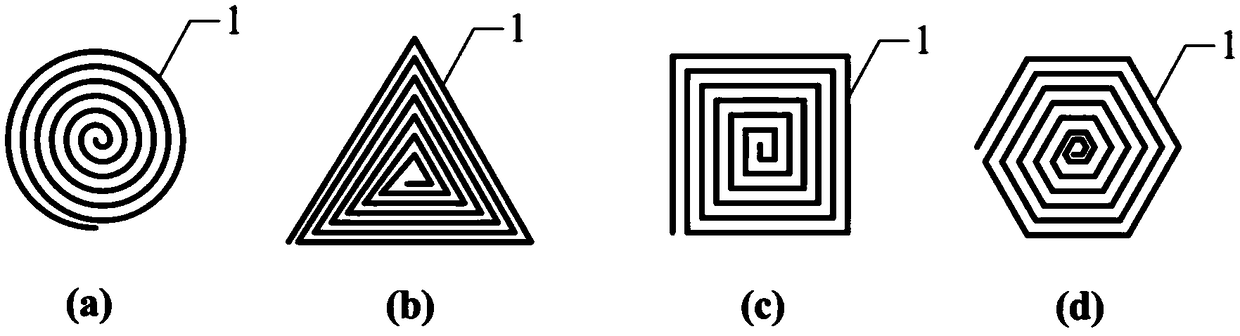

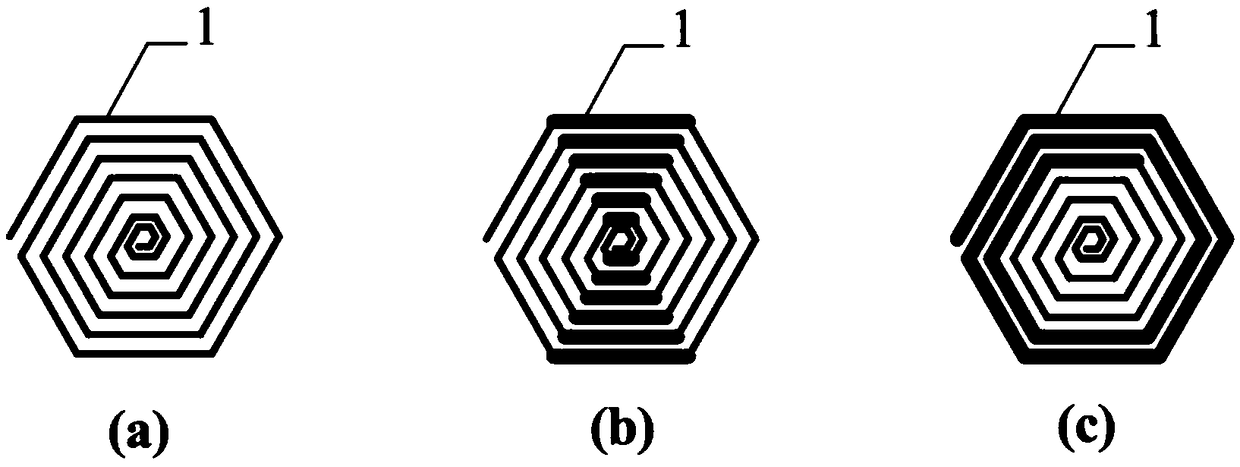

[0041] Step 1, open the drawing software, input the design shape, wire diameter, thickness, and gap parameters of the repetitive structure 1 of the anti-lightning strike unit, and create a CAD model of the repetitive structure 1 of the anti-lightning strike unit;

[0042] Step 2, according to the CAD model of the anti-lightning strike unit repeating structure 1 in step 1, select a small punching machine, and input the running track parameters of the punching head at the same time;

[0043] Step 3, take the smooth and flat metal foil and fix it on the flat grinding tool, start the small stamping machine in step 2, make the stamping head move according to the running track parameters, remove the excess part of the metal foil, and keep the anti-lightning unit to repeat the structure 1 metal parts;

[0044] Step 4, repeating steps 3 ...

Embodiment 1

[0047] The anti-lightning strike unit repeating structure 1 is a spiral square shape, the metal foil is copper, and the lightning strike resisting unit repeating structure 1 is 0.2 mm thick. Concrete preparation process is as follows:

[0048] Step 1. Open the drawing software, input the following parameters: the shape is a spiral regular quadrilateral shape with a size of 300mm×300mm, the diameter of the wire is 1mm, and the gap between adjacent rings of wire is 1mm to create a CAD model.

[0049] Step 2. According to the CAD model in step 1, select a small punching machine, and input the running trajectory parameters of the punching head at the same time, and the diameter of the punching head is 0.8mm.

[0050] Step 3. Select a smooth and flat copper foil with a thickness of 0.2mm and a size of 320mm×320mm, fix it on the flat abrasive tool, start the small punching machine, make the punching head move according to the running track parameters, remove the excess part of the m...

Embodiment 2

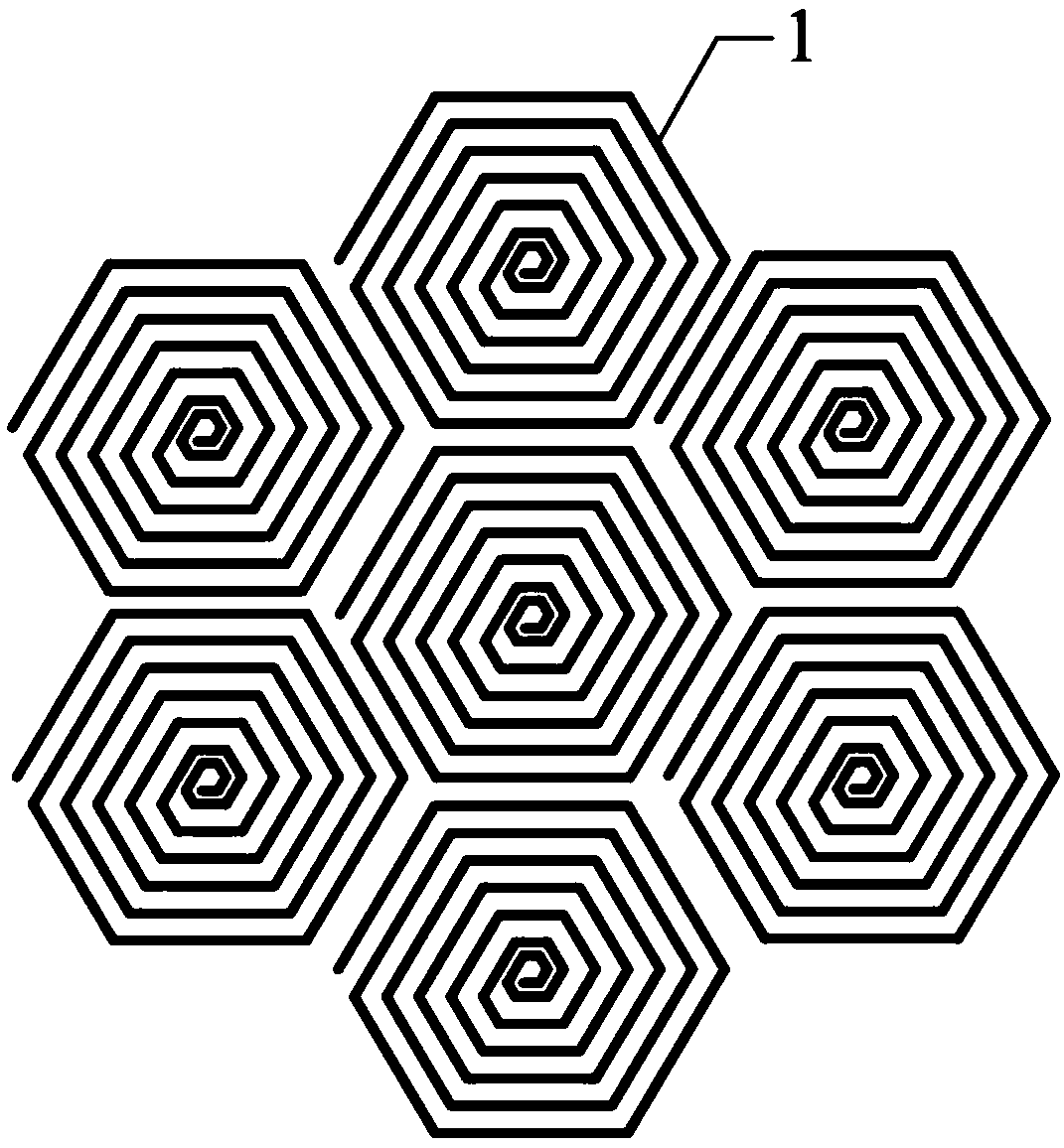

[0054] The anti-lightning strike unit repeating structure 1 is a hexagonal shape, the metal foil is copper, and the lightning strike resisting unit repeating structure 1 has a thickness of 0.1 mm. Concrete preparation process is as follows:

[0055] Step 1. Open the drawing software and input the following parameters: the shape is a hexagonal shape and the side length is 300mm, the wire diameter is 1mm, and the gap between adjacent rings of wire is 3mm to create a CAD model.

[0056] Step 2. According to the CAD model in step 1, select a small punching machine, and input the running trajectory parameters of the punching head at the same time. The diameter of the punching head is 2.8mm.

[0057] Step 3. Select a smooth and flat copper foil with a thickness of 0.1mm and a size of 850mm×850mm, fix it on the flat abrasive tool, start the small punching machine, make the punching head move according to the running track parameters, remove the excess part of the metal foil, and keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com