Construction method of suspension type steel-structured lighting skylight

A construction method and steel structure technology, applied in skylight/dome, building structure, roof, etc., can solve problems affecting vertical lifting equipment layout, high support height, difficult to cover, etc., so as to reduce the amount of construction work and avoid Overall hoisting, the effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The construction method of the hanging type steel structure daylighting skylight of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] The hanging type steel structure daylighting skylight construction method of the present invention comprises the following steps:

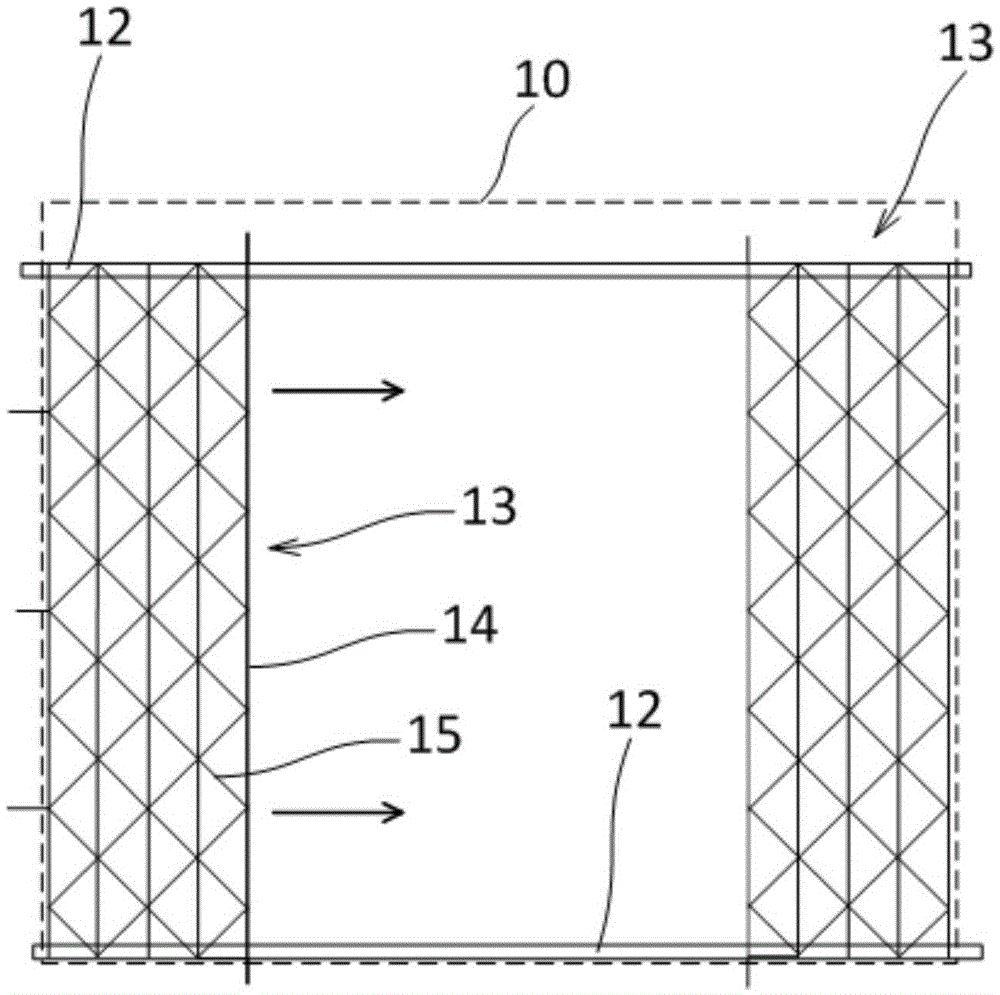

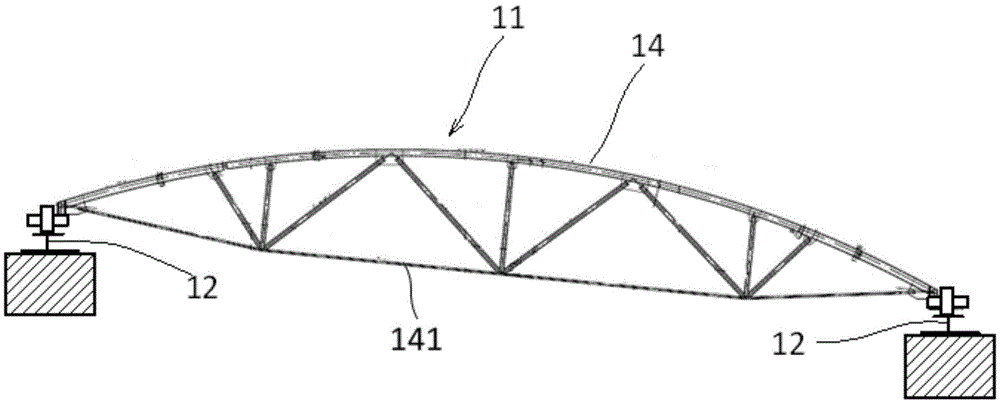

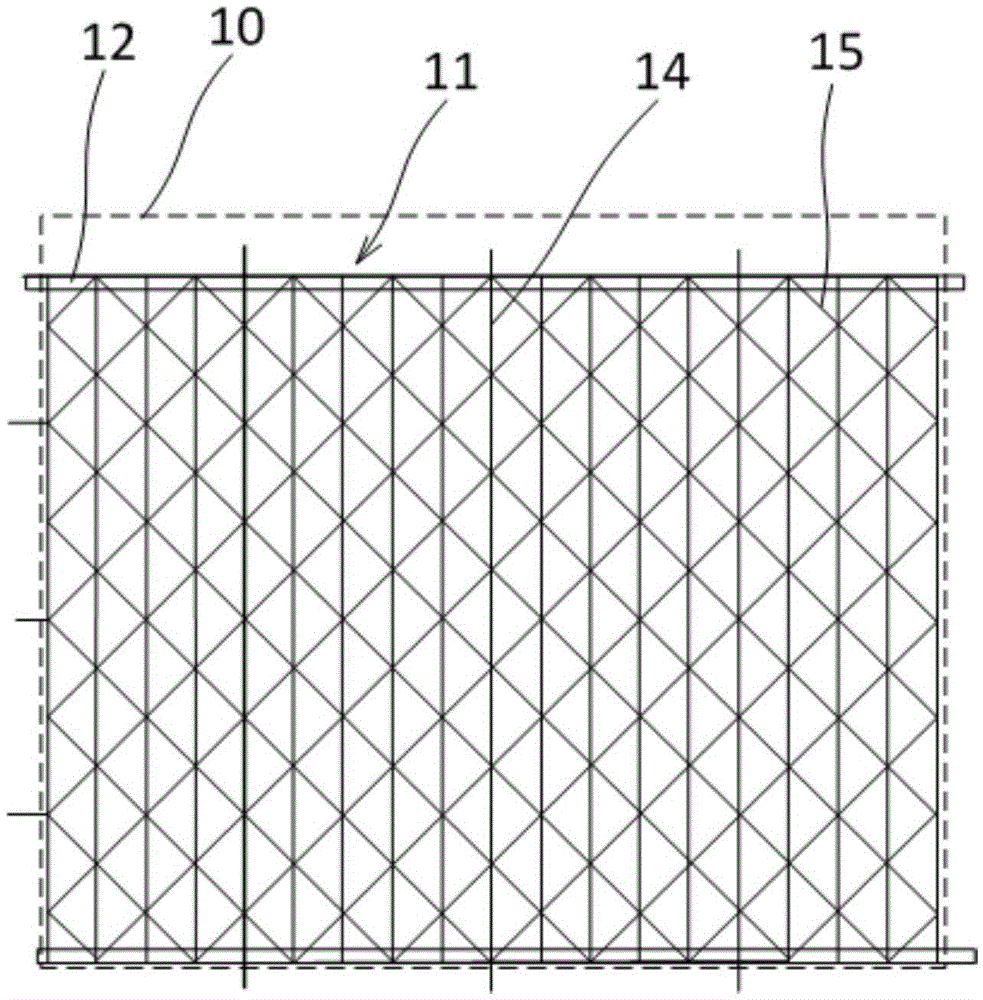

[0038] 1) Assemble the steel structure of the daylighting skylight. Such as figure 2 and image 3 As shown, in this embodiment, the daylighting skylight steel structure is assembled on the upper surface of the fifth floor slab. The skylight steel structure includes a steel structure grid 15 and a prestressed truss 14 supported on the lower surface of the steel structure grid 15 . The prestressed truss 14 can strengthen the steel structure grid 15, so that the steel structure of the daylighting skylight can have a larger span.

[0039] In this embodiment, the steel structure of the daylighting skylight has a relatively large area, so the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com