Steel-structure composite square wood

A technology of steel structure and wood square, which is applied in the direction of building structure, formwork/formwork components, and on-site preparation of building components, which can solve the problems of large loss of wooden beams, moisture, and accelerated corrosion, so as to slow down the rate of decay The speed of corrosion and the rectangular steel, the service life is improved, and the effect of avoiding position movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

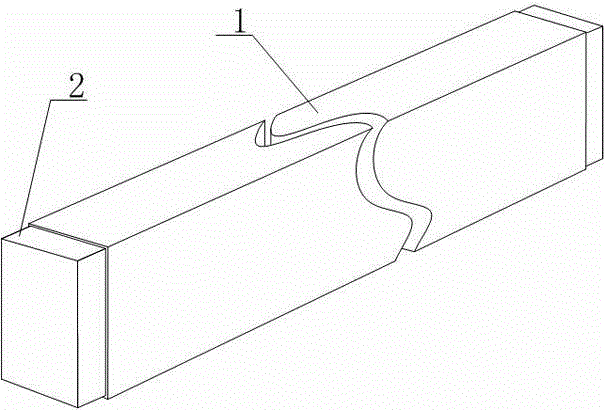

[0019] Such as figure 1 As shown, a steel structure composite wooden square of the present invention comprises rectangular steel 1, the cross section of rectangular steel 1 is rectangular, its size is 60*40mm, and its length is 1-4 meters, each interval of 20cm is a model, which can form A series of length models, the wall thickness of which is 0.7mm, install the sleeper body 2 in the rectangular steel 1 by means of interference fit, and both ends of the sleeper body 2 protrude 2cm from the end of the rectangular steel 1, as the production process error, the length of both ends of the sleeper body 2 protruding from the end of the rectangular steel 1 can be controlled within 1 to 3 cm, and the sleeper body 2 uses a whole wooden beam, or it can refer to a connected wooden beam, generally not Two or more wooden beams are used to directly fill in, but for the part of rectangular steel with a small length, short wooden beams can also be used to directly fill.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com