Mould for manufacturing housing unit from inside to outside in manner of integral forming

A technology for inner molds and houses, which is applied to the preparation of ceramic molding cores, ceramic molding mandrels, and building components on site. It can solve the problems of many connection nodes, high construction costs, and large material consumption, and achieve satisfactory functions. Demand, rich shape and texture, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

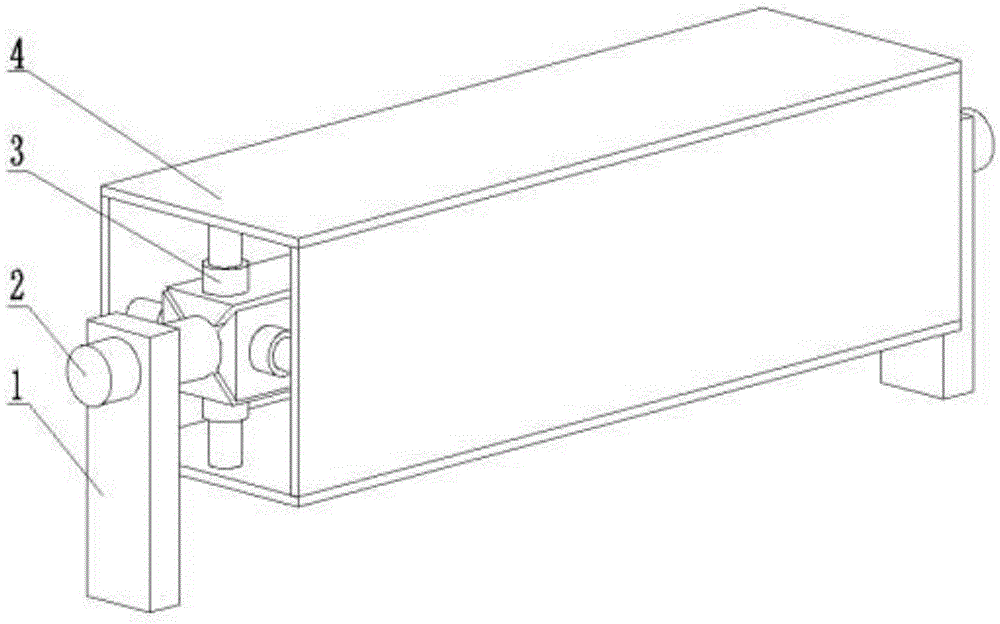

[0024] Combine below Attached picture The mold provided by the present invention is described in detail.

[0025] The mold of the present invention is composed of a support 1, a central shaft 2, a hydraulic rod 3, an inner mold cylinder 4, a printing platform guide rail 5, a forming unit cylinder 6, a printing platform support 7, a printing platform 8, a printing flat head 9 and a feeding pipe 10.

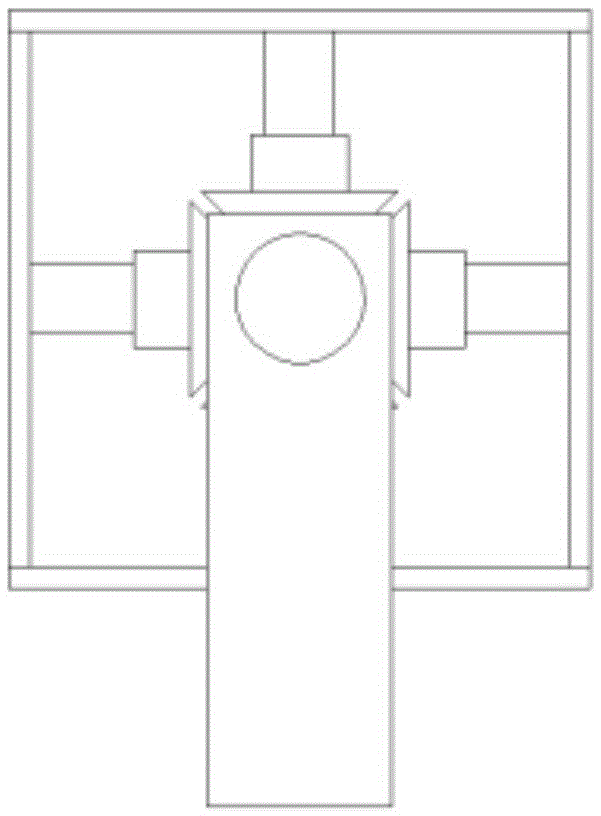

[0026] The mold support 1 is composed of two columns with one end provided with a through hole perpendicular to the axis, the two ends of the central axis 2 pass through the through hole of the support 1 respectively, and the inner mold cylinder 4 is coaxially sleeved outside the central axis 2. The platform 8 is arranged on the outer side of the inner mold barrel 4; a hydraulic rod 3 perpendicular to the axis is arranged between the central axis 2 and the inner mold barrel 4.

Embodiment 2

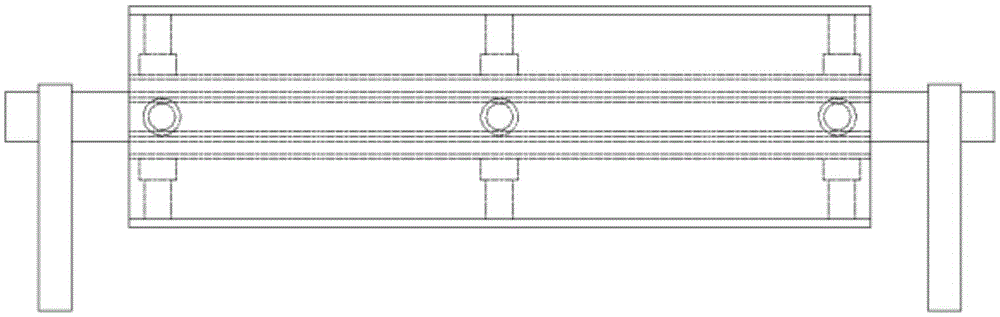

[0028] The three groups of hydraulic rods 3 are respectively arranged at the two ends and the middle of the central axis 2 , corresponding to the two ends and the middle of the inner wall of the inner mold barrel 4 . Each group consists of 3 hydraulic rods arranged radially and equidistantly on the central axis 2.

Embodiment 3

[0030] The printing platform guide rails 5 are longitudinally arranged on both sides of the inner mold cylinder 4 in parallel, and the pulleys arranged at both ends of at least two support members of the printing platform across the inner mold cylinder 4 are arranged on the guide rails.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com