low permeability reservoir co 2 Method for Determining Limit Well Spacing of Flooding Technology

A definite method and low-permeability technology, applied in wellbore/well components, earthwork drilling and production, production fluids, etc., can solve problems such as low recovery, inability to achieve displacement, low permeability of low-permeability reservoirs, etc., to achieve Broad prospects for popularization and application, increasing economically recoverable reserves, and strengthening the effect of resource base development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

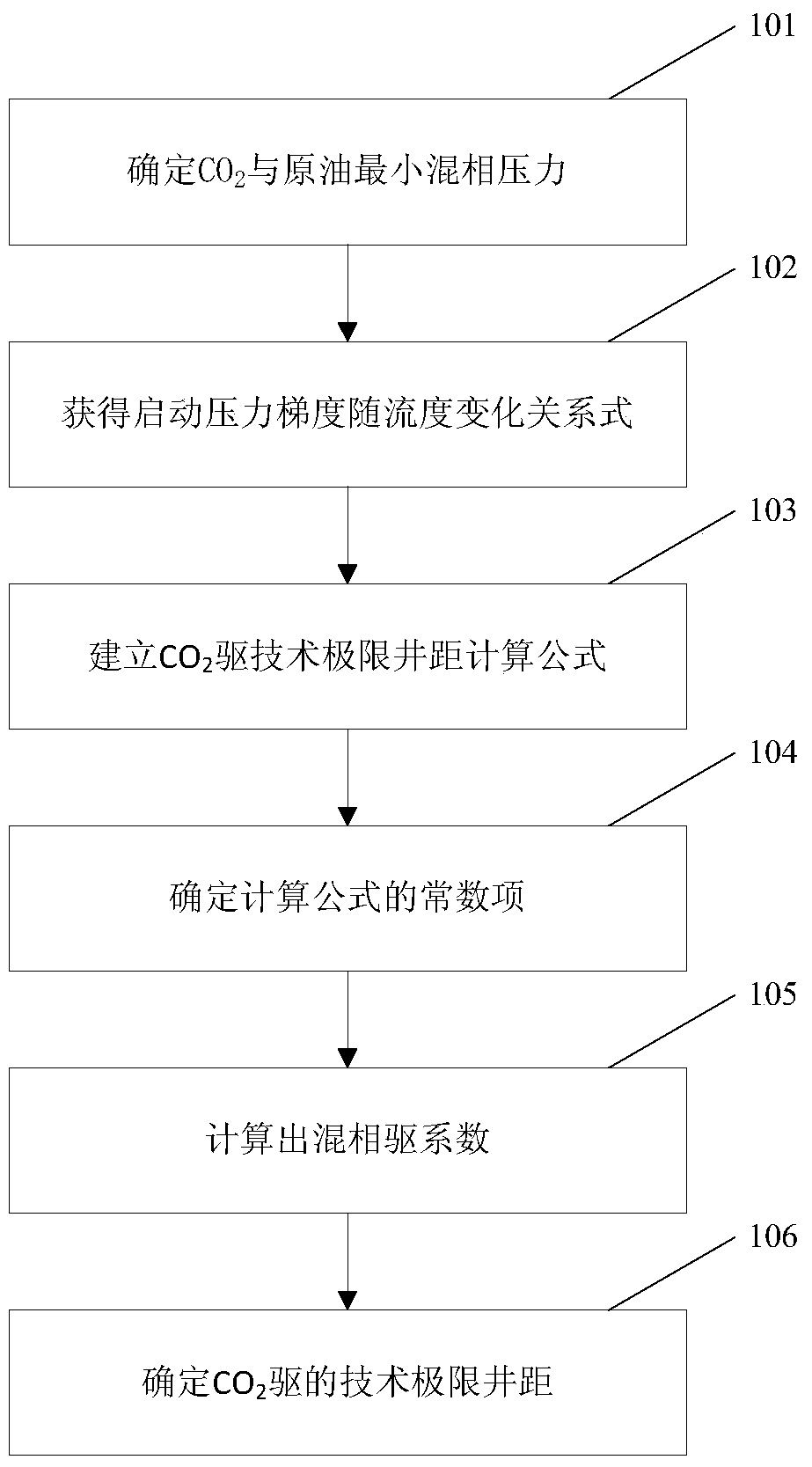

[0032] In order to make the above-mentioned and other objects, features and advantages of the present invention more obvious and understandable, preferred embodiments are listed below in conjunction with the accompanying drawings, which are described in detail as follows.

[0033] Such as figure 1 As shown, figure 1 It is the low permeability reservoir CO of the present invention 2 A flowchart of a specific embodiment of the method for determining the limit well spacing of the flooding technology.

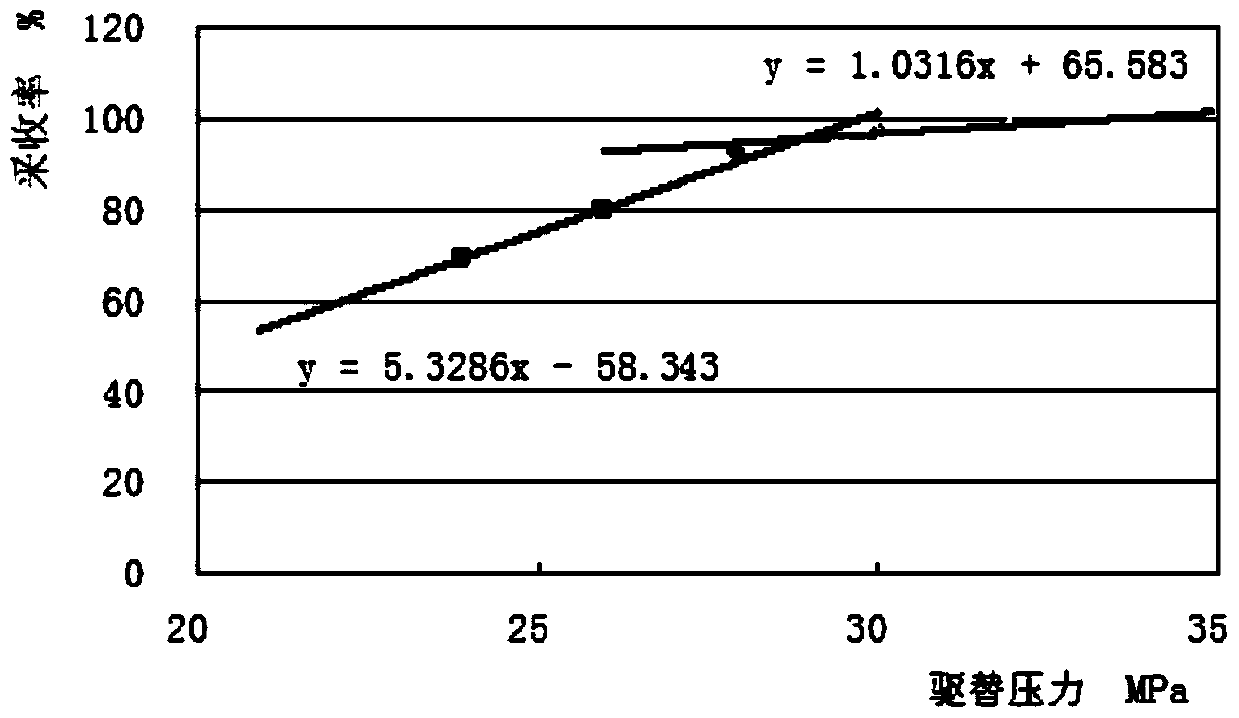

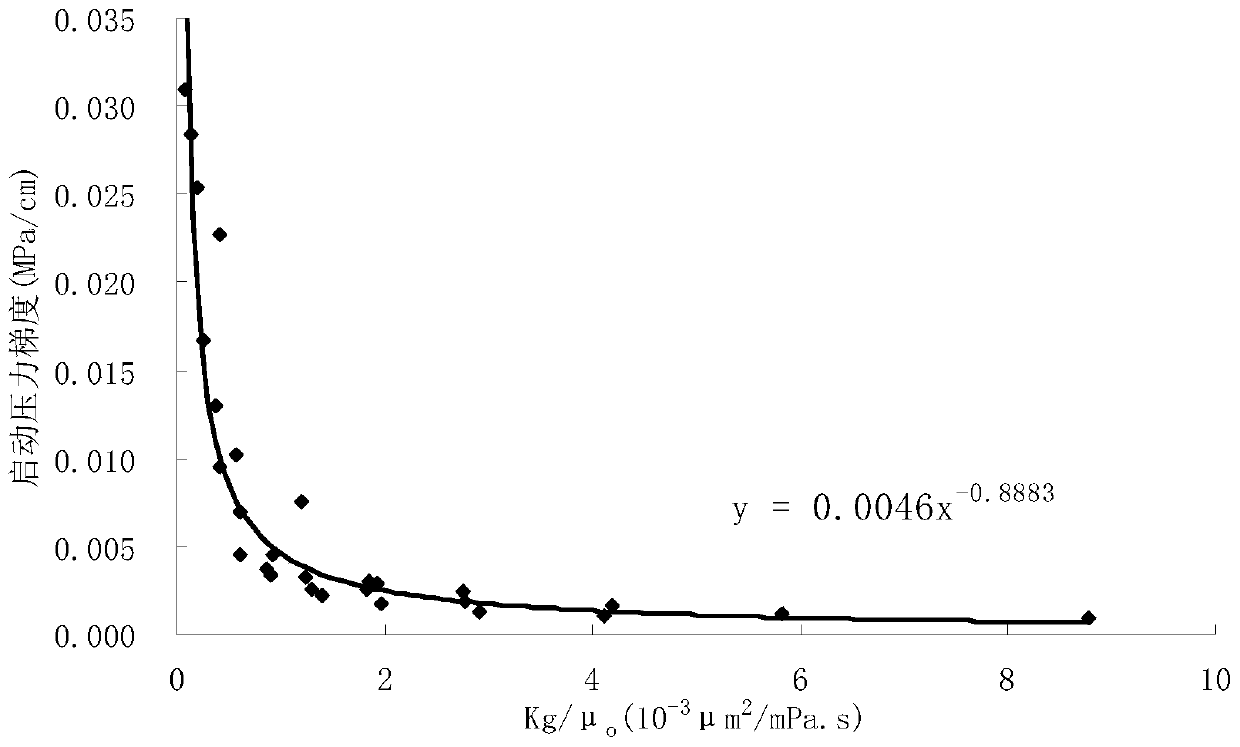

[0034] In step 101, select 5 different displacement pressures to carry out the long thin tube displacement experiment. First, the thin tube model is saturated with the formation crude oil under the formation temperature and displacement pressure, and the back pressure is controlled by the back pressure valve as required for the experiment. pressure. After the system is balanced, use 9.00cm 3 / h inject CO 2 Displacement with gas, measure the oil and gas fluid produced during the displace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com