Integral exhaust manifold cylinder head with water jacket

A technology for exhaust manifolds and cylinder heads, which is applied to cylinder heads, cylinders, liquid cooling, etc., can solve the problems of cylinder head durability, engine knock characteristics deterioration, engine performance deterioration, etc., to improve knock characteristics and combustion characteristics , Reduce noise/vibration, improve combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

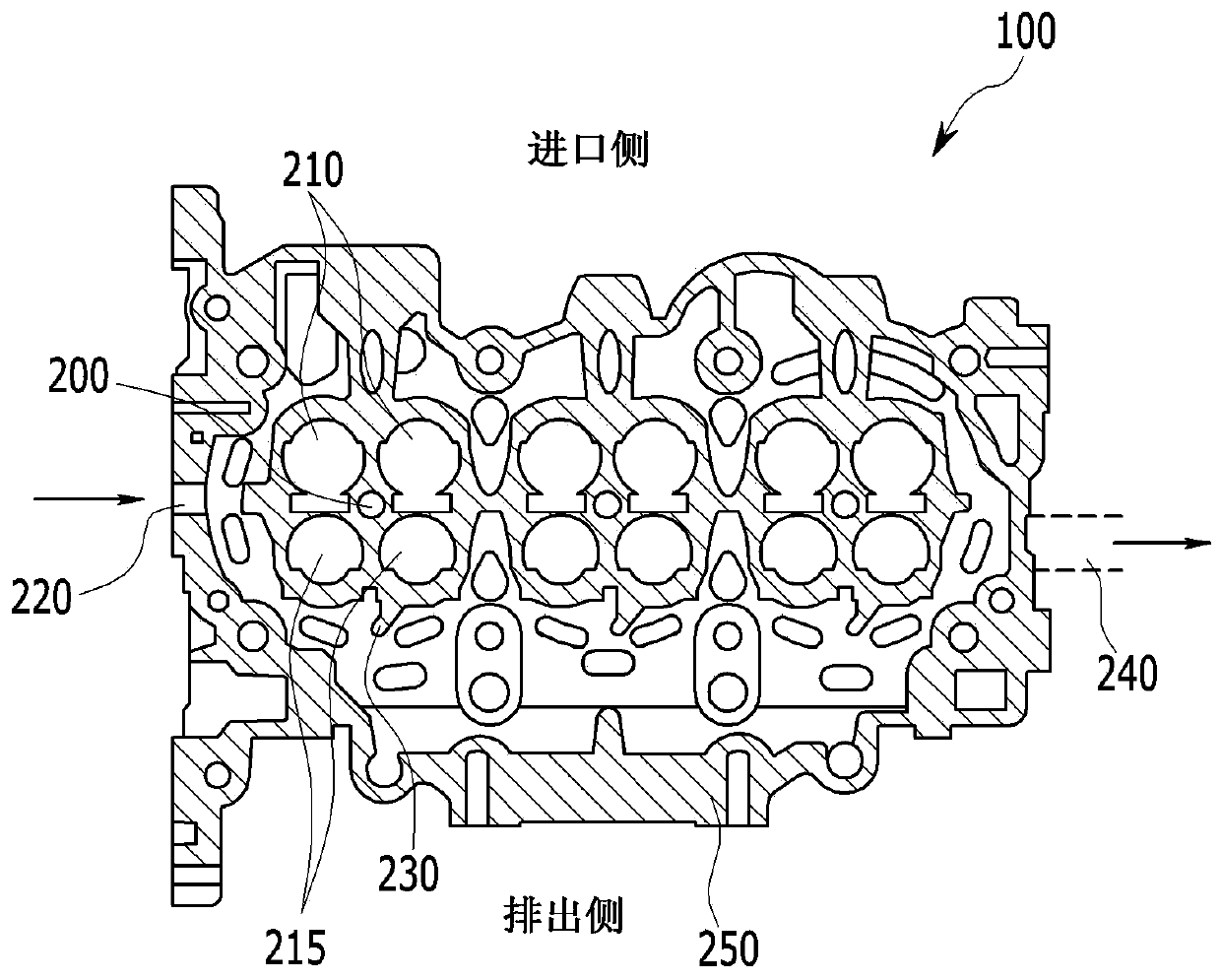

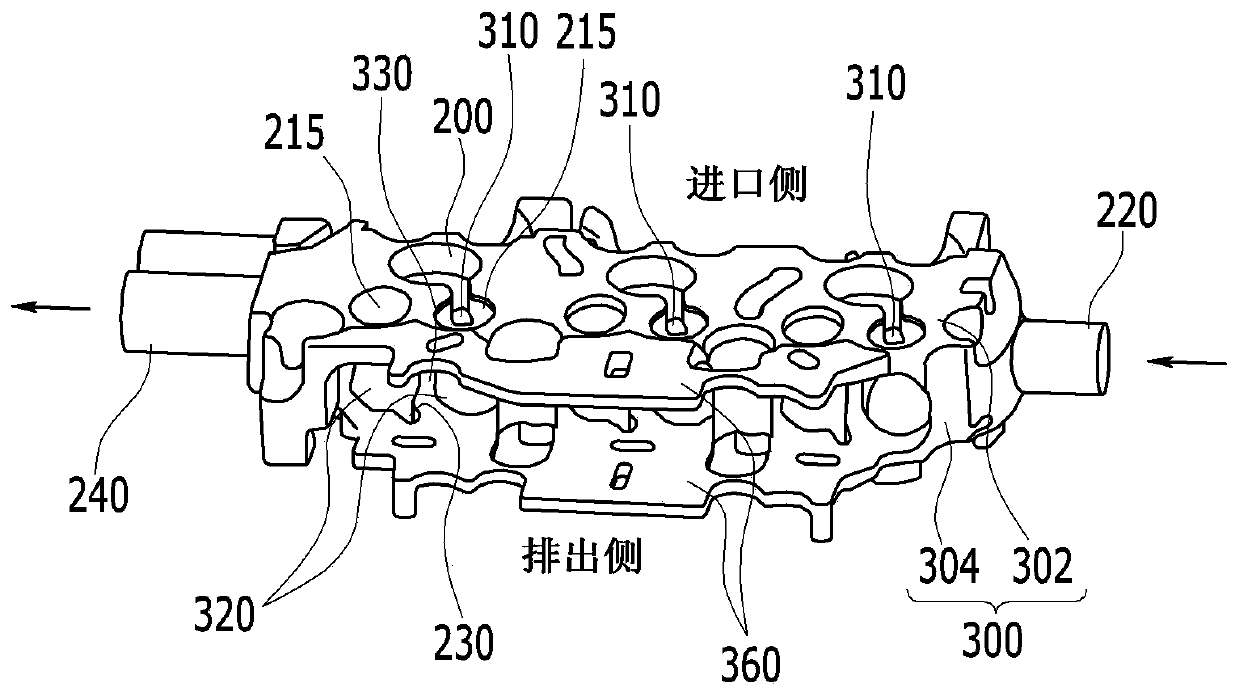

[0023] Hereinafter, an exemplary embodiment according to the inventive concept will be described in detail with reference to the accompanying drawings.

[0024] In an exemplary embodiment of the present invention, a cylinder head integrally formed with an exhaust manifold cools the exhaust manifold through an exhaust manifold water jacket extending on the exhaust side. Since the coolant flows mainly to the exhaust manifold, the cooling efficiency near the combustion chamber (exhaust port or spark plug hole) is reduced.

[0025] Therefore, the coolant needs to flow to the exhaust manifold towards the exhaust port or near the spark plug hole.

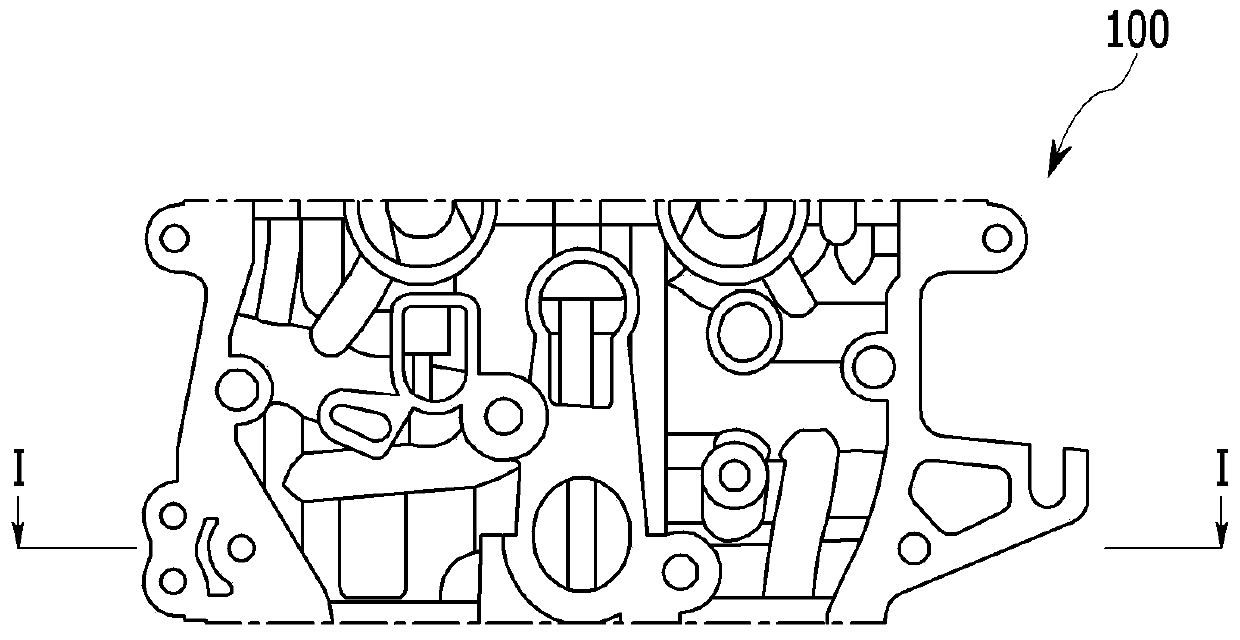

[0026] figure 1 is a view illustrating one side of an exhaust manifold-integrated cylinder head having a water jacket according to an exemplary embodiment of the inventive concept. figure 2 is along figure 1 A sectional view of the cylinder head taken along the line I-I in . image 3 is a perspective view of a head water jacket forme...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap