Multi-stage blade centrifugal wheel

A centrifugal wheel and blade technology, applied in non-variable-capacity pumps, pump components, components of pumping devices for elastic fluids, etc., can solve problems such as stable operation, reduce pressure loss, reduce loss, The effect of widening the stable working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

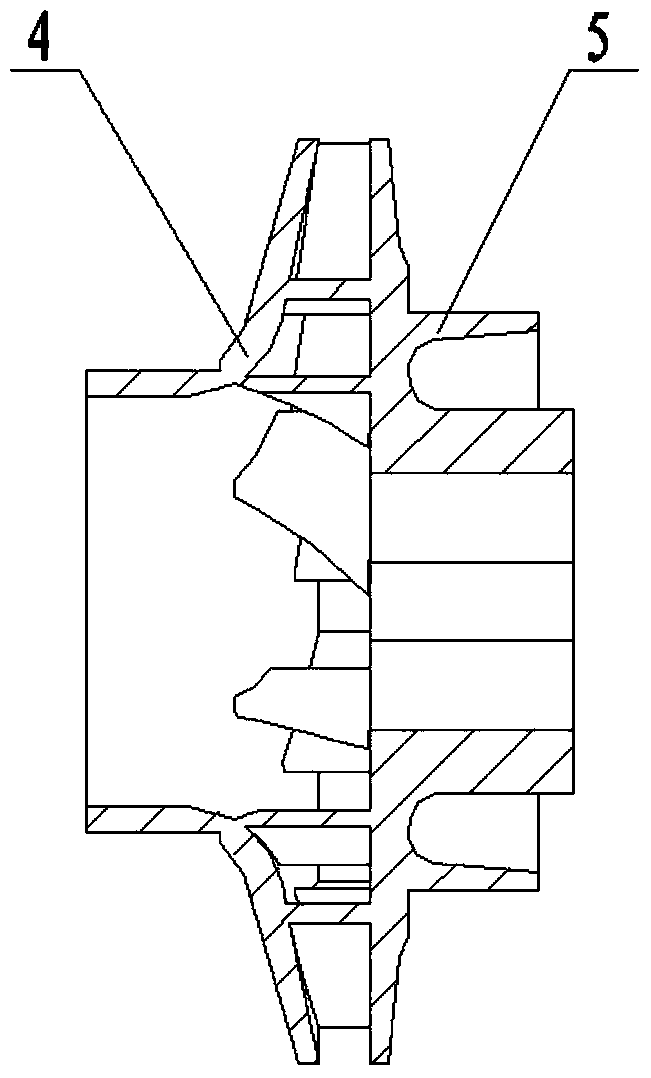

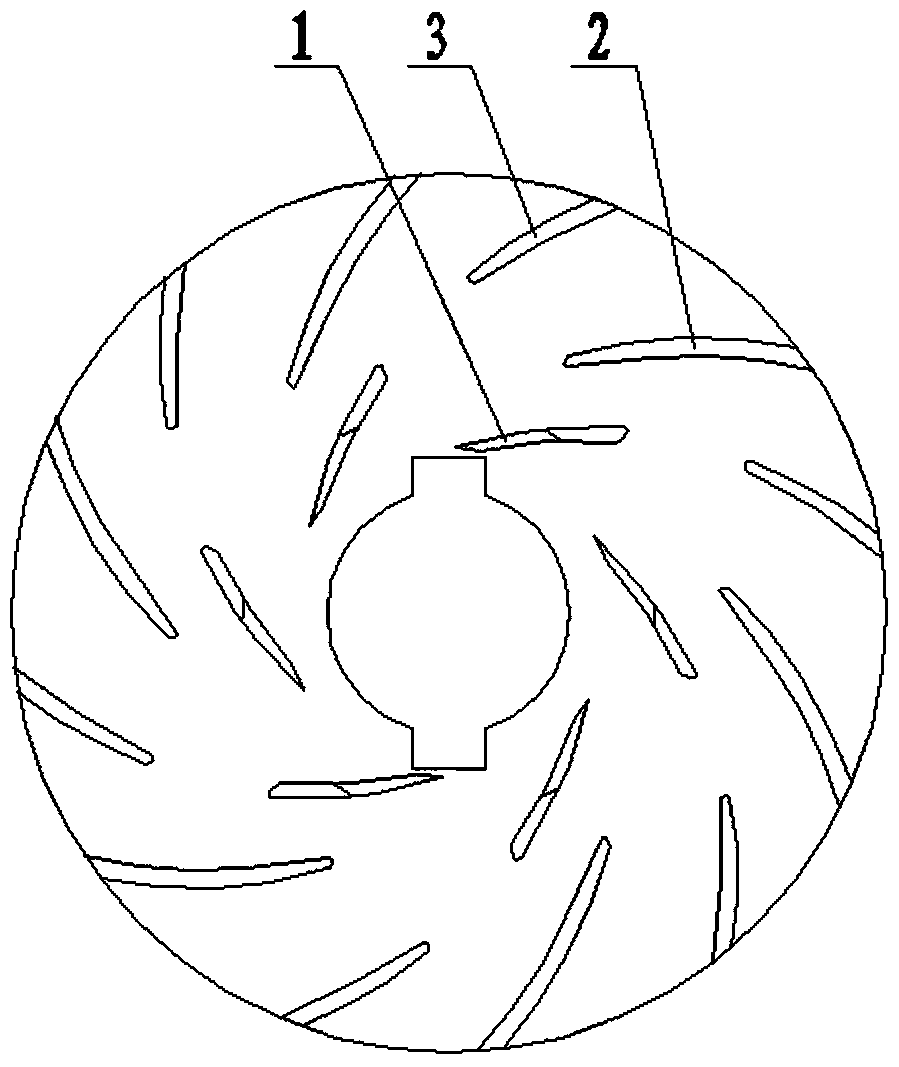

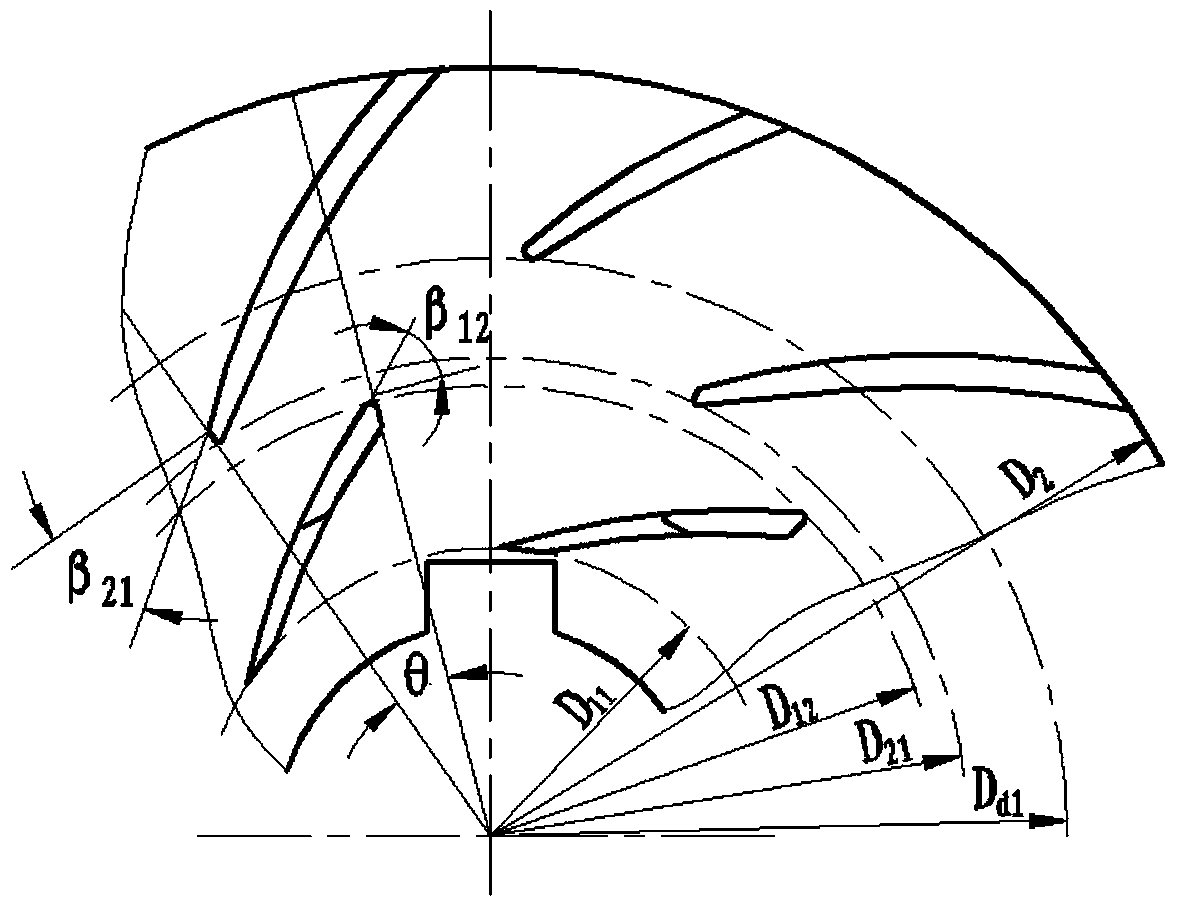

[0024] figure 1 It is a structural schematic diagram of the multi-stage blade centrifugal wheel of the present invention, which is also a preferred embodiment of the present invention. The first-stage blade 1, the second-stage blade 2 and the short blade 3 of the multi-stage blade centrifugal wheel of the present invention are integrally processed with the hub 5, and on one surface of the hub 5, a plurality of blades of the first-stage blade 1 follow the same The installation angle is arranged on the inner periphery, and multiple blades of the second-stage blade 2 are arranged on the periphery according to the same installation angle. The first-stage blades 1 and the second-stage blades 2 are alternately distributed step by step, and the short blades 3 are distributed on the second-stage blades. between. The first-stage blade 1 can adopt the same blade shape as the second-stage blade 2, and the first-stage blade outlet placement angle β 12 Greater than or equal to the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com