Desuperheating and decompressing device for steam

A technology for reducing temperature and decompression, and steam, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., to achieve good atomization quality, ensure equipment performance, and low noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawings and examples.

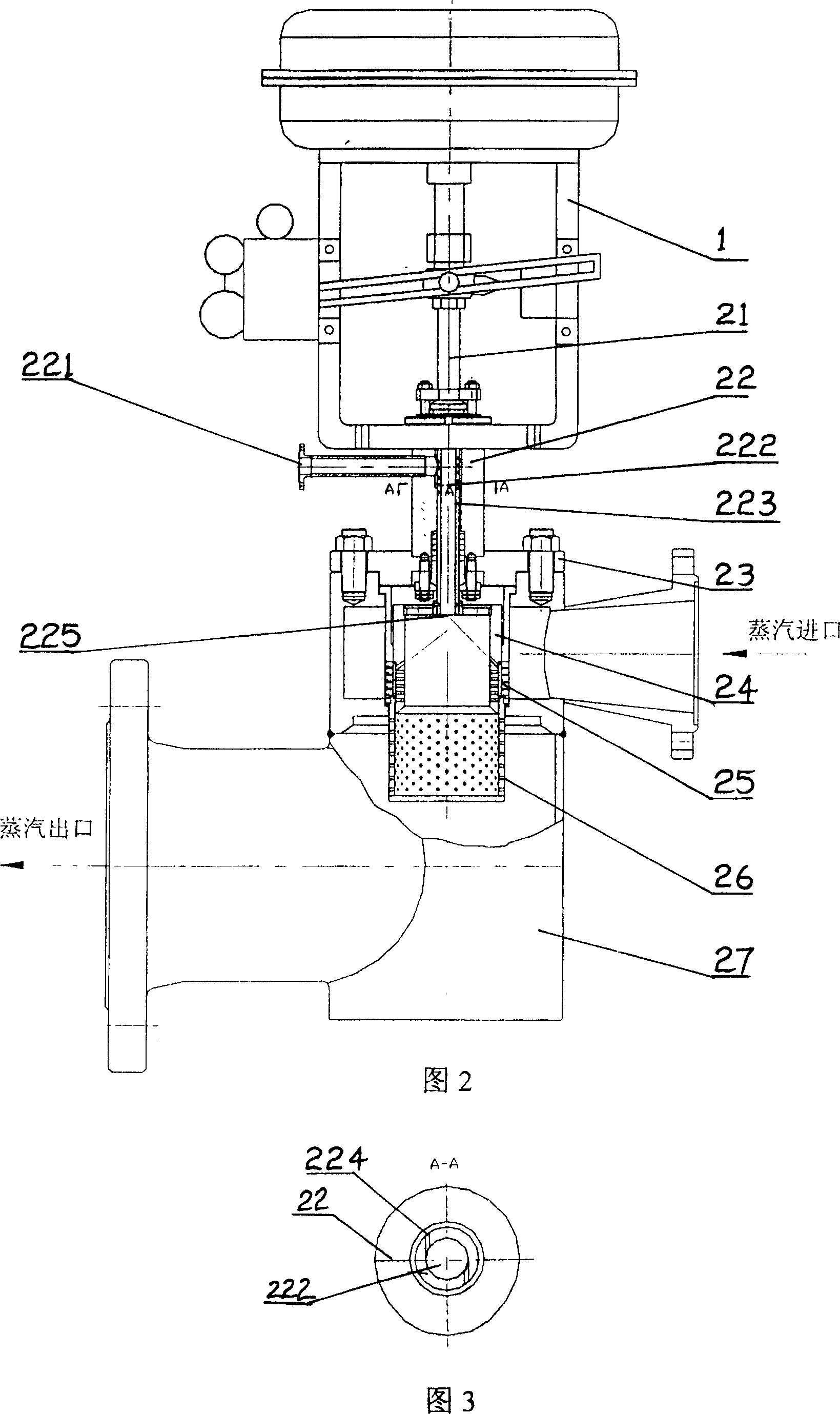

[0018] The electric actuator 1 can be driven by an electric motor or a cylinder as the power source. The electric actuator 1 and the desuperheating water flow regulating valve 3 are commercially available qualitative products. The valve stem 21 is made of stainless steel and is a cage valve. Core 24, steam inlet valve cover 25, structural steam outlet mouthpiece 26 are all made of stainless steel, and steam delivery pipe 27 is made of heat-resistant steel or carbon steel.

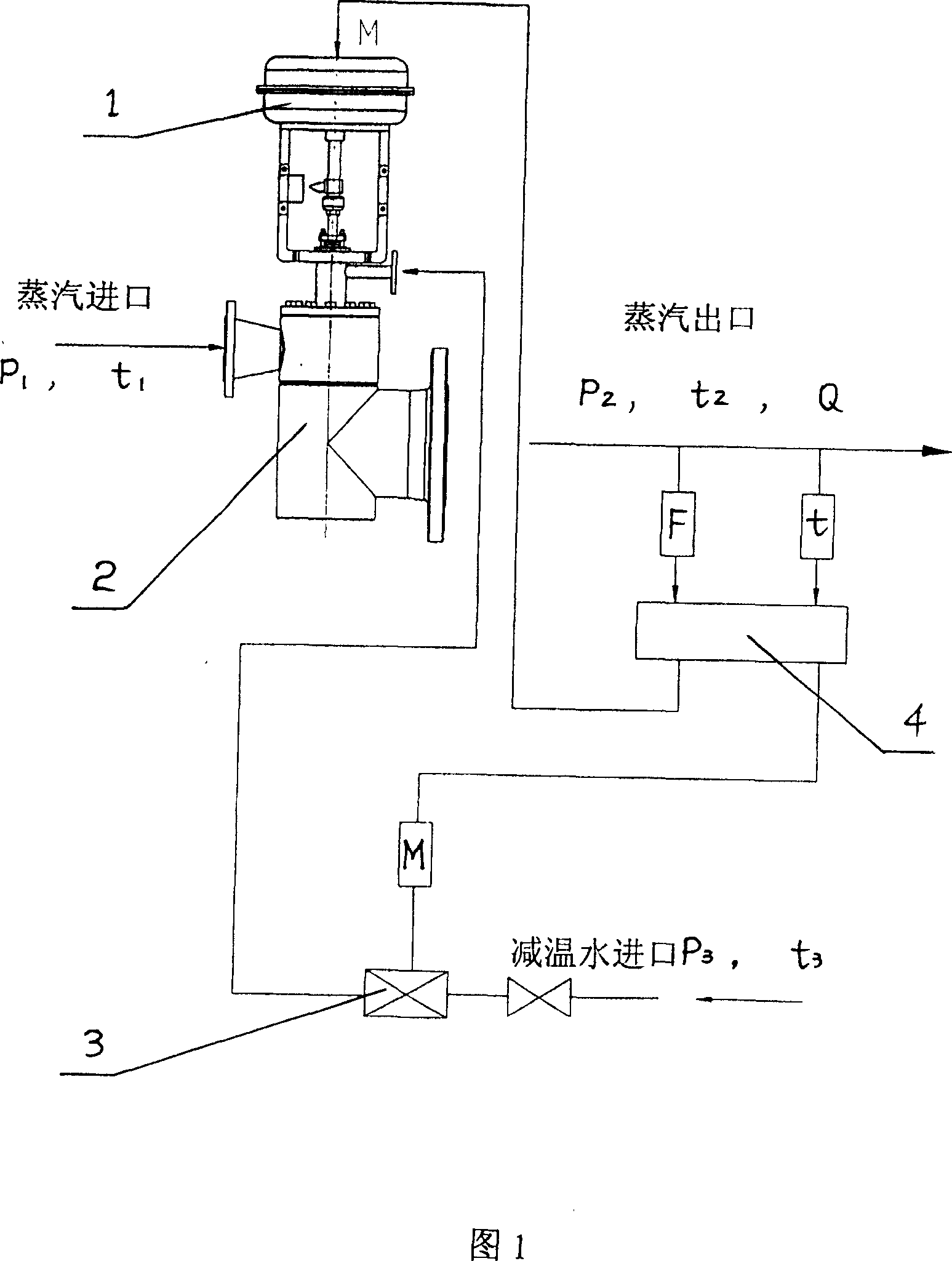

[0019] Structurally, the present invention is composed of an electric actuator 1 , a desuperheating and pressure reducing valve 2 , a desuperheating water flow regulating valve 3 and a temperature, pressure and flow regulating system 4 . The temperature and pressure reducing valve 2 includes a valve stem 21, a casing 22, a casing 23 installed on the upper part of the steam delivery pipe 27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com